Chapter 14 Fault Codes and DescriptionsME300

14-25

Fault treatment parameter

Pr.06-45

0: Warn and continue operation

1: Warn and ramp to stop

2: Warn and coast to stop

3: No warning

Reset method Manual reset

Reset condition Immediately reset

Record When Pr.06-45=1 or 2, OPL3 is a “Fault”, and the fault is recorded.

Cause Corrective Actions

Unbalanced three-phase

impedance of the motor

Replace the motor.

Check if the wiring is incorrect.

Check the cable and replace it if necessary.

Check the motor’s internal wiring. If the fault still exists, replace the motor.

Check if the motor is a

single-phase motor.

Choose a three-phase motor.

Check if the current sensor is

broken.

Check if the control board cable is loose. If yes, reconnect the cable and run the

drive to test. If the fault still exists, return to the factory for repair.

Check if the three-phase current is balanced with a current clamp meter. If the

current is balanced and the OPL3 fault still exists, return to the factory for repair.

Check if the drive capacity is larger

than the motor capacity.

Choose the drive that matches the motor capacity.

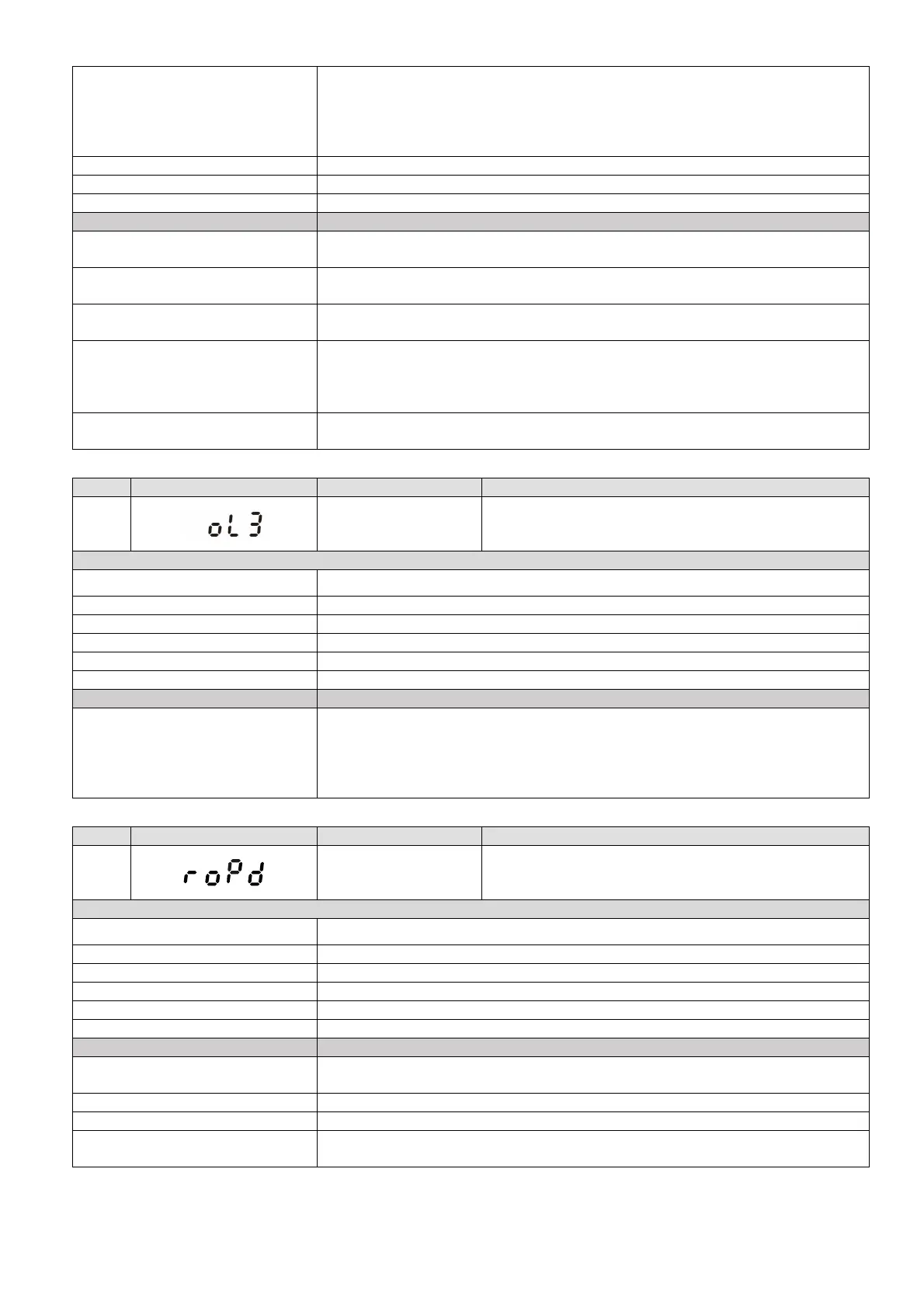

ID No. Display on LCM Keypad Fault Name Fault Descriptions

87

Overload protection at

low frequency

(oL3)

Low frequency and high current protection

Action and Reset

Action level Software detection

Action time Immediately act

Fault treatment parameter N/A

Reset method Manual reset

Reset condition Immediately reset

Record Yes

Cause Corrective Actions

The drive operates in the low

frequency range (High HP: below

15 Hz; Low HP: below 5 Hz) and

IGBT temperature (High HP: 20ºC;

Low HP: 50ºC).

1. Improve heat dissipation

2. Raise power

3. Change the control mode

4. Reset or reduce the carrier frequency

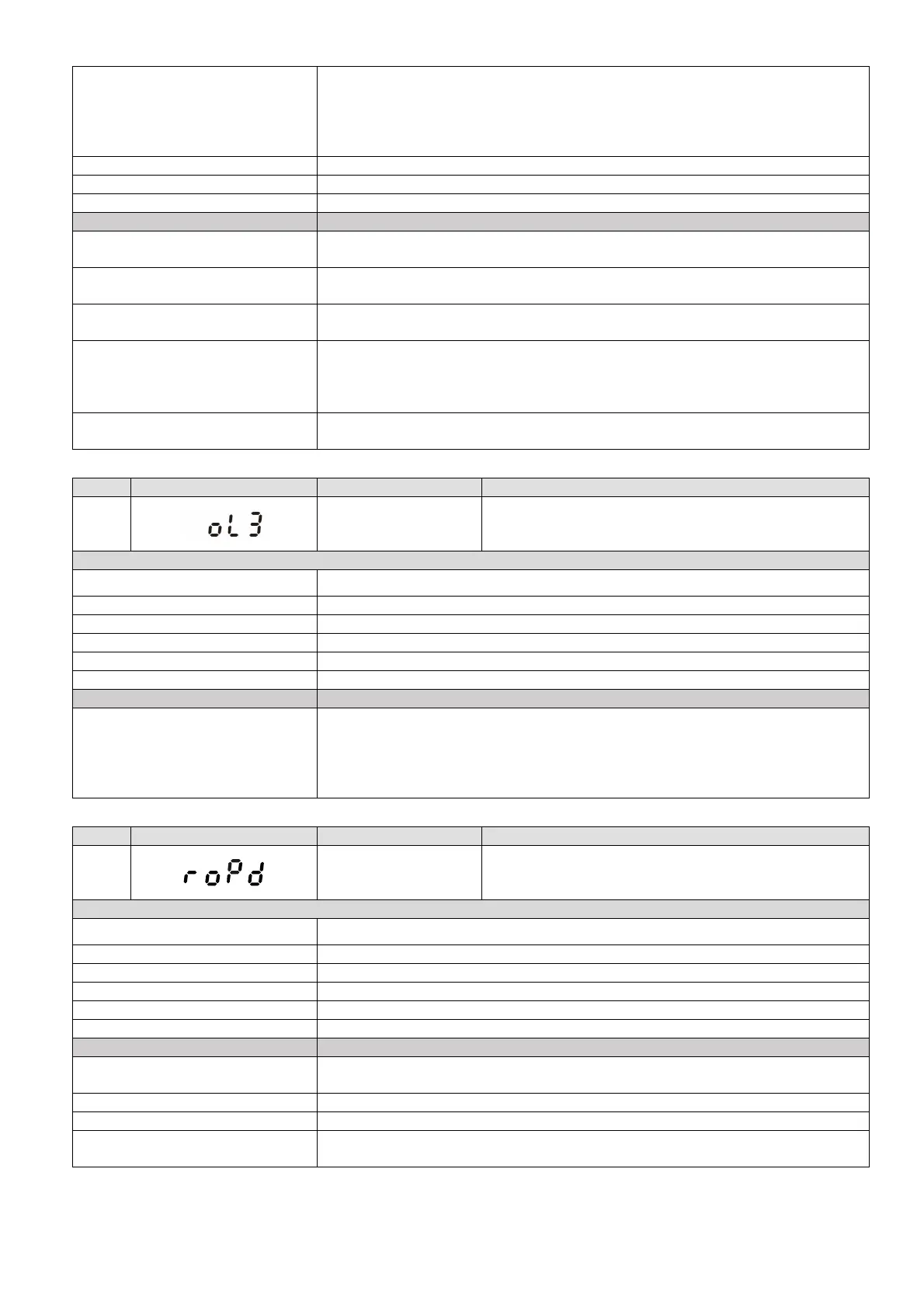

ID No. Display on LCM Keypad Fault Name Fault Descriptions

89

Rotor position

detection error

(RoPd)

Rotor position detection error protection

Action and Reset

Action level Reset the software.

Action time Immediately act

Fault treatment parameter N/A

Reset method Manual reset

Reset condition Immediately reset

Record Yes

Cause Corrective Actions

Check if the motor cable is

abnormal or broken.

Check or replace the cable.

Motor coil error Replace the motor.

Hardware failure IGBT broken. Return to the factory for repair.

Drive’s current feedback line error

Cycle the power. If RoPd still occurs during operation, return to the factory for

repair.

Loading...

Loading...