Chapter 16 PLC Function Applications│CP2000

16-123

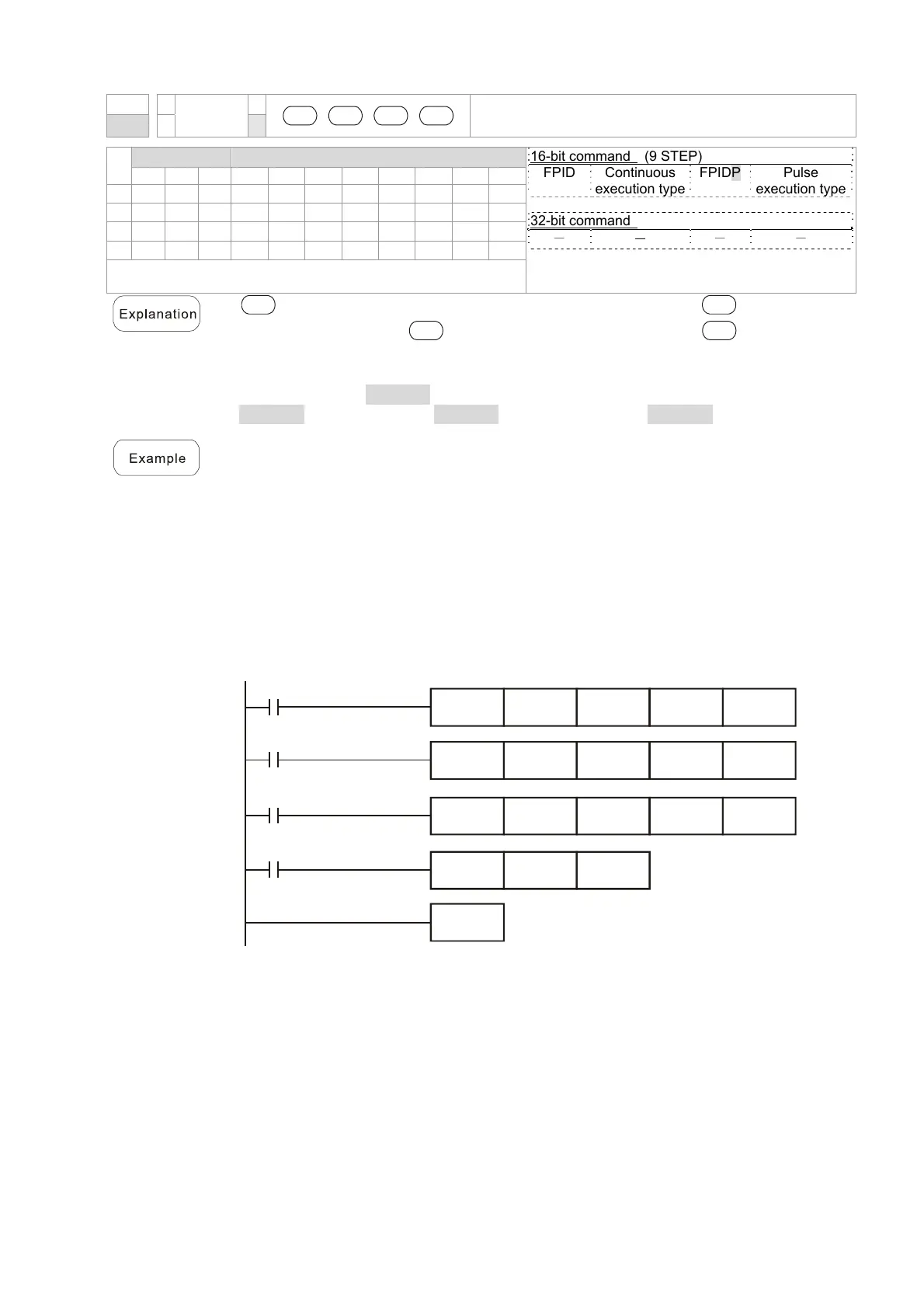

API

FPID

S1 S2 S3 S4

Driver PID control mode

141

P

Bit device Word device

16-bit command (9 STEP)

FPID Continuous

execution type

FPIDP Pulse

execution type

32-bit command

- - - -

Flag signal: none

X Y M K H KnX KnY KnM T C D

S1

* *

*

S2

* *

*

S3

* *

*

S4

* *

*

Notes on operand usage: none

S1

: PID reference target value input terminal select.

S2

: PID function

proportional gain P.

S3

: PID function integral time I.

S4

: PID function

differential time D.

The FPID command can directly control the driver's feedback control of

PID parameter Pr.08-00 PID reference target value input terminal selection,

Pr.08-01 proposal gain P, Pr.08-02 integral time I, and Pr.08-03 differential time D.

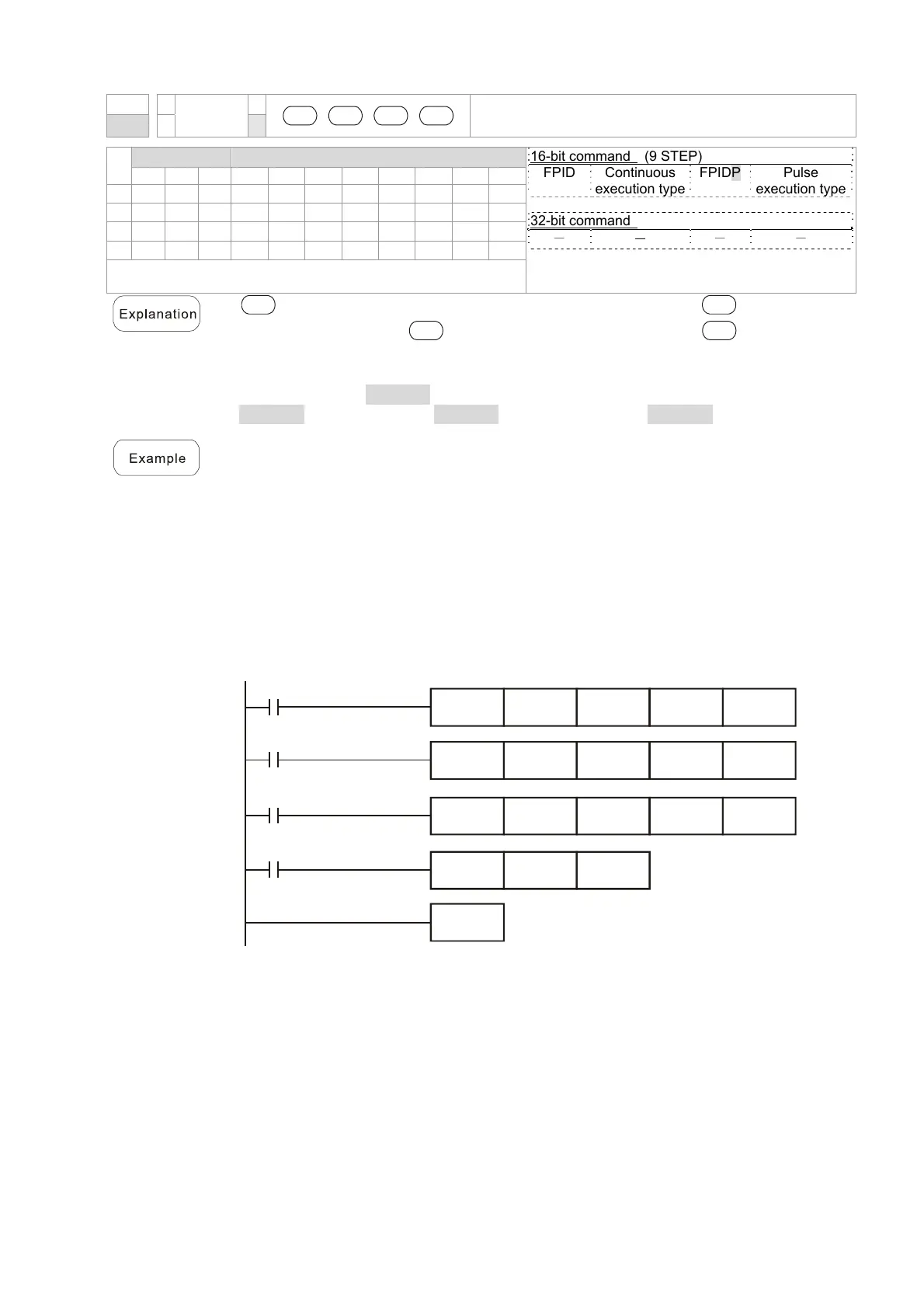

When M0=On, the set PID reference target value input terminal selection is 0 (no

PID function), the PID function proportional gain P is 0, the PID function integral

time I is 1 (units: 0.01 sec.), and the PID function differential time D is 1 (units:

0.01 sec.).

When M1=On, the set PID reference target value input terminal selection is 0 (no

PID function), the PID function proportional gain P is 1 (units: 0.01), the

PID function integral time I is 0, and the PID function differential time D is 0.

When M2=On, the set PID reference target value input terminal selection is 1

(target frequency input is controlled from the digital keypad), the PID function

proportional gain P is 1 (units: 0.01), the PID function integral time I is 0, and the

PID function differential time D is 0.

D1027: Frequency command after PID operation.

END

H0

M2

M1

M0

M1000

H1

H0

H0

H1

H1

H1 H1

H0 H0

H0 H0

FPID

MOV

D1027

D1

FPID

FPID

Loading...

Loading...