What to do if Dentsply Sirona Furnace shows 'SENSOR BROKEN' error?

- JJoseph GrantJul 30, 2025

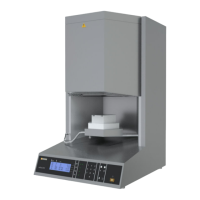

If your Dentsply Sirona Furnace displays a 'SENSOR BROKEN' error, it could be due to loose thermocouple connections. Ensure these connections are secure. Alternatively, the thermocouple itself might be defective and require replacement.