Blast chiller Service Manual

15

Rev 07/04/2015

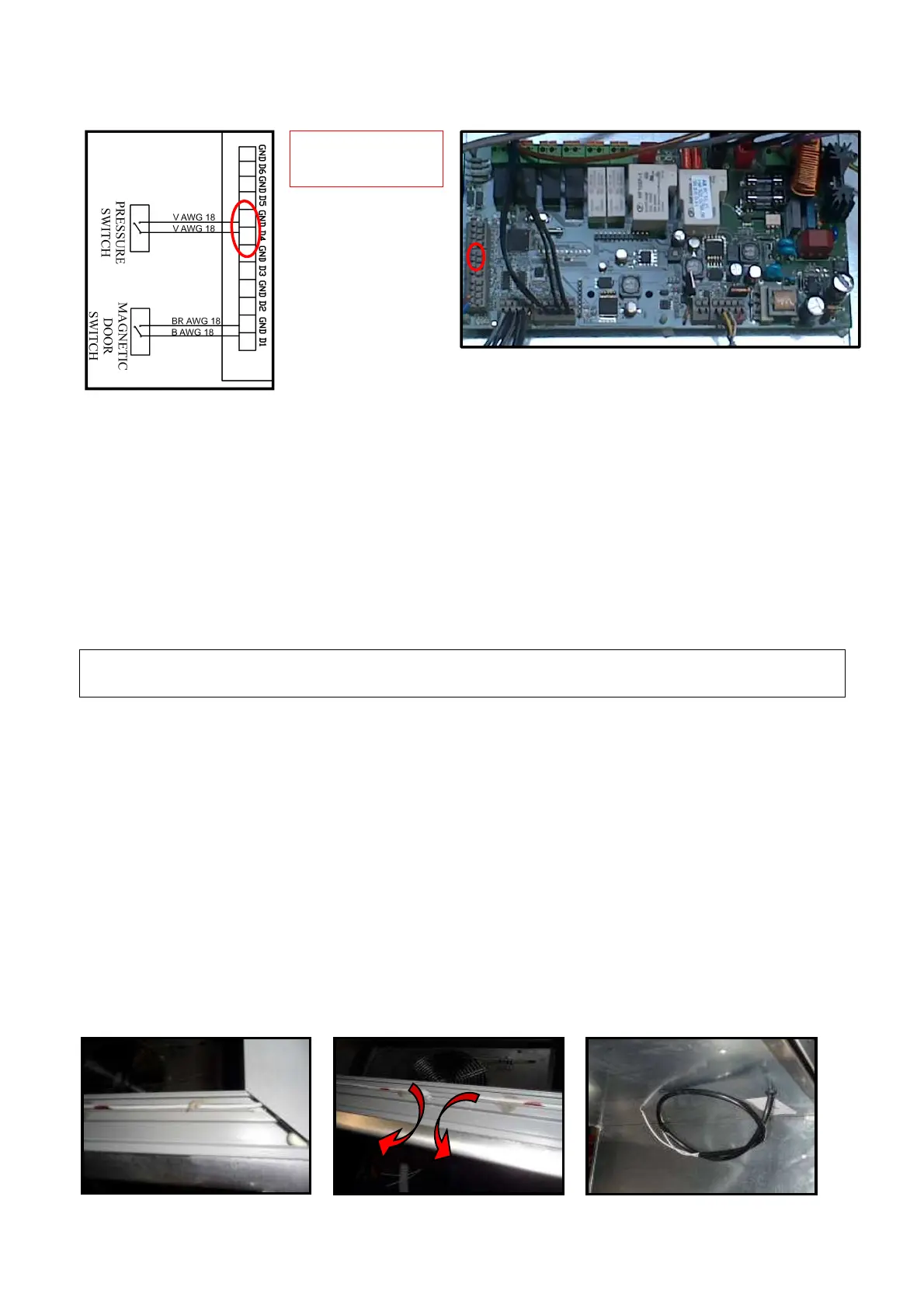

Newest self contained models (D.O.M. above January 2014) will only have a high pressure

switch. Once the pressures return to the normal range, the pressure switch will reset

automatically. Newest remote application (D.O.M. above January 2015) won’t have an

alarm connection with the pressure switch, but will be used to pump down by low pressure,

or to cut out compressor in case of high pressure.

3.3.2 Pressure Switch Working Principles – Pump Down

Remote application are equipped with a double pressure switch. A solenoid valve is used

to feed refrigerant to the evaporator. This valve will be closed when setpoint temperature is

reached in the cabinet, allowing compressor to pump down until pressure switch trips due

to low suction pressure. The pressure switch will cut out compressor contactor’s coil in this

case, either for low pressure (pump down) or high pressure (safety).

NOTE: No high pressure alarm message will be displayed from the controller in

case of remote chillers working in pump down configuration.

3.3.3 Pressure Switch Factory Setting

The factory setting for the pressure switch is as follows. Do not change these settings!

High pressure limit = 29 barg (425psig)

Low pressure limit = 0 barg (0 psig)

Differential = 1,2 barg (18 psig)

3.4. DOOR FRAME HEATER

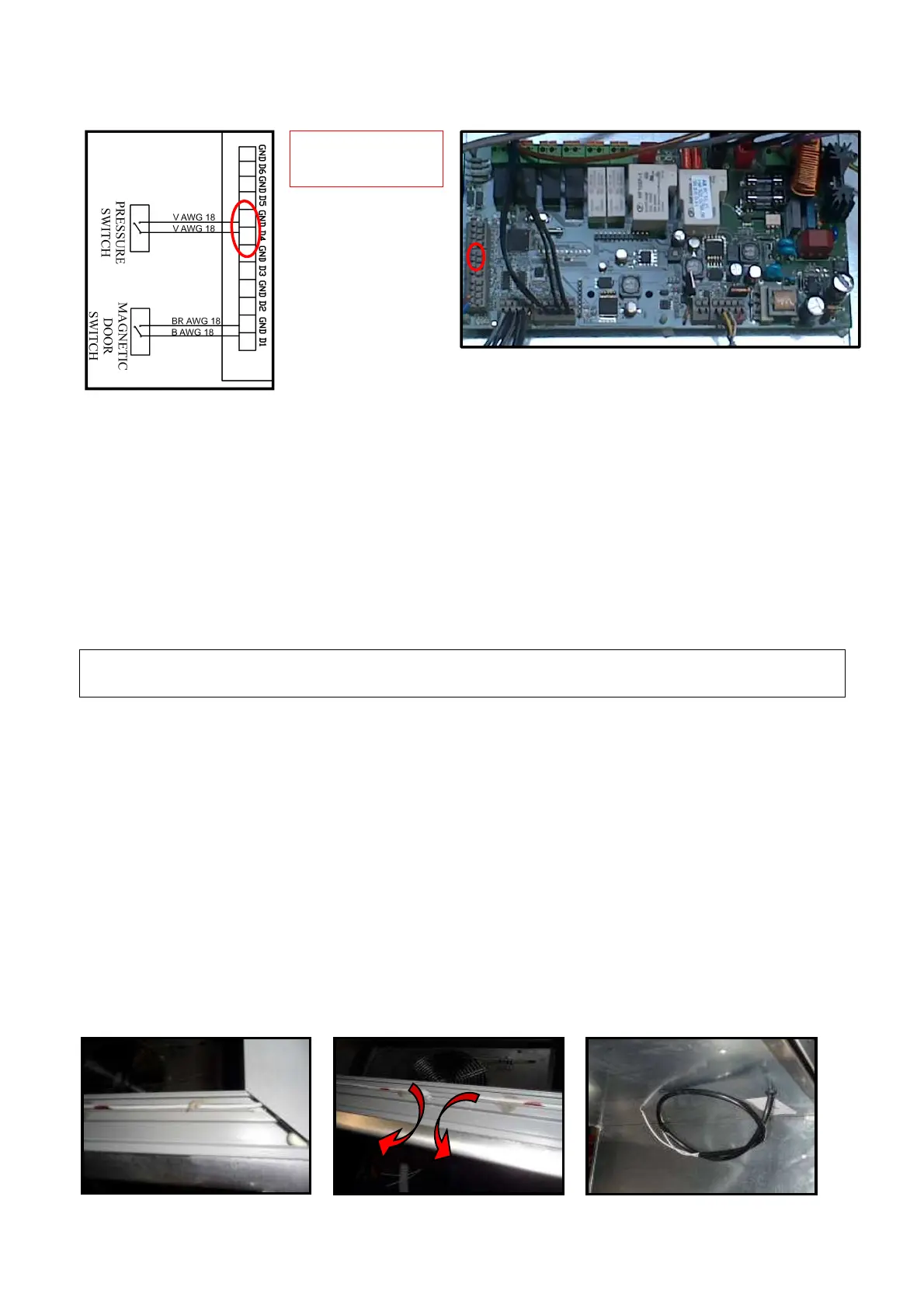

Both Shock Freezer and Blast Chiller units come equipped with a door frame

heater to prevent frost build up on the door gasket. The heater may be either

115V or 220V depending on the model/rating. For 220V 3-phase units (or 220V

single-phase units with no neutral), the door frame heater is connected between

two live mains. The heater runs around the frame, under a plastic strip cover.

Electrical connections run through the lower cabinet panel to the electrical

component box.

VERSION

Loading...

Loading...