3

PART 1

INSTALLATION

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE, COMBUSTIBLE OR CORROSIVE

VAPOURS AND LIQUIDS IN THE VICINITY OF THIS

APPLIANCE.

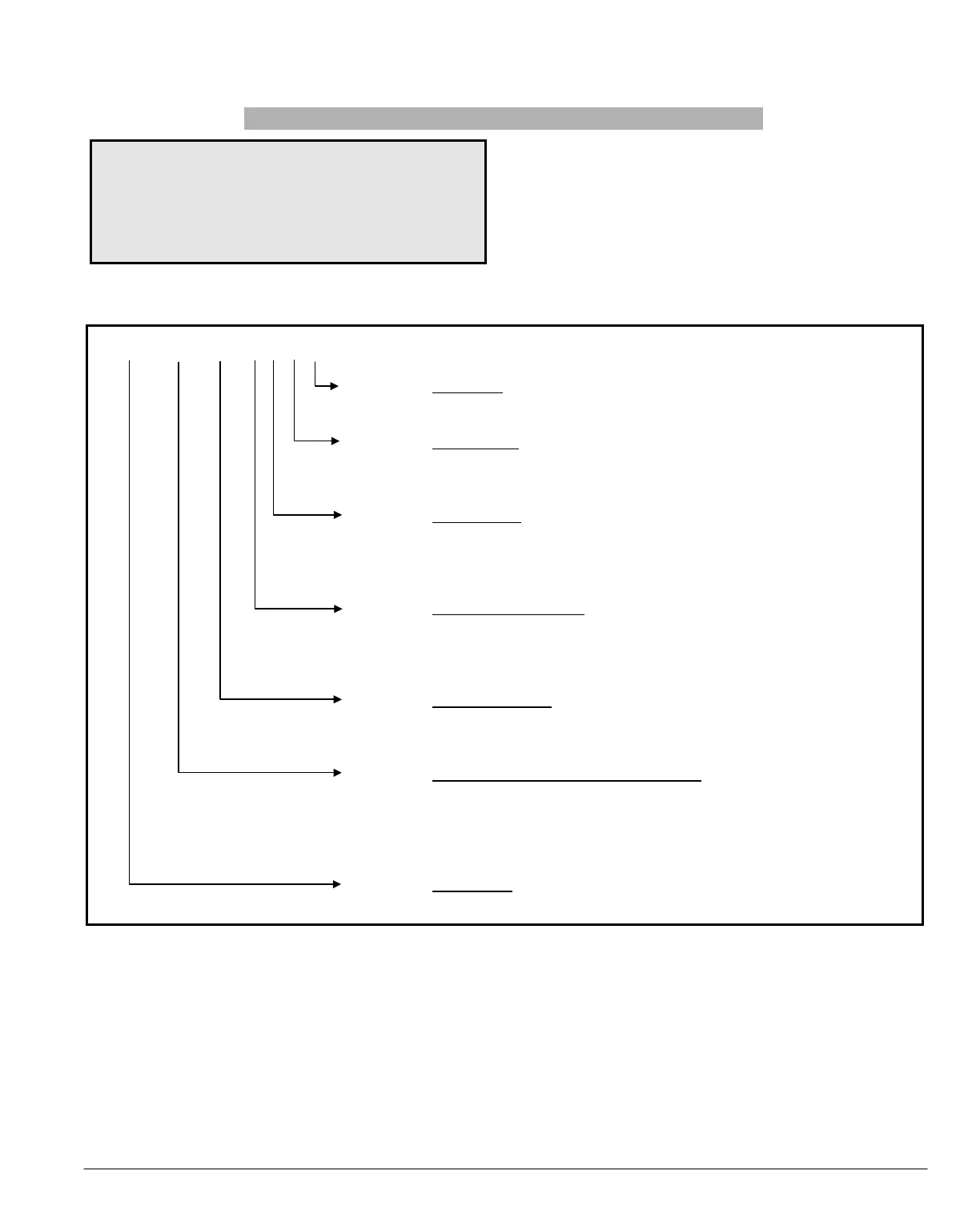

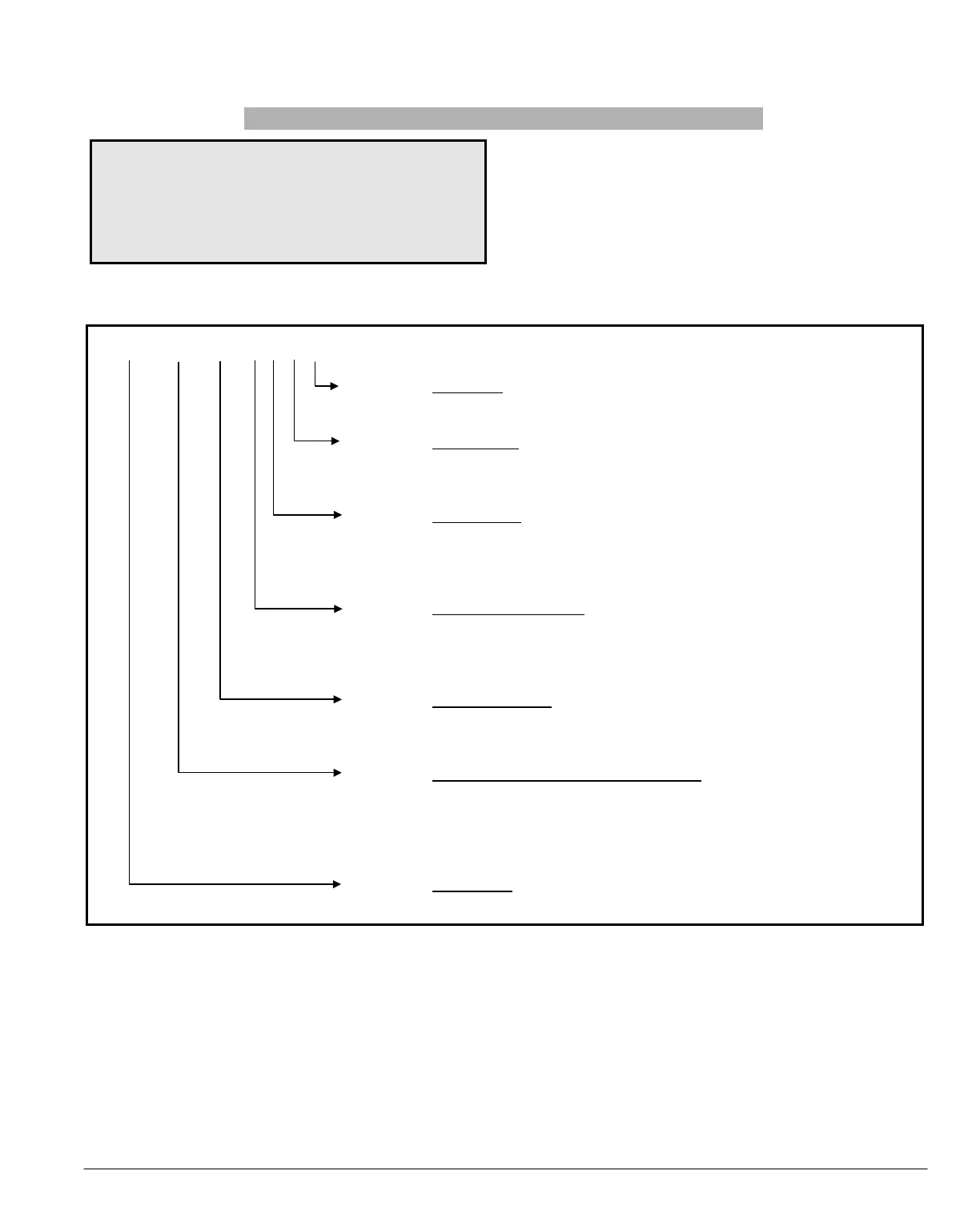

1) HGC LINE

HGC boilers and water heaters are natural or propane

gas fired units and are available with inputs ranging

from 404,000 BTU/h to 1,1515,000 BTU/h. The model

designations are as follows:

FIGURE 1

HGC Series

HGC - 0000 - XX – X X X X

Aquastat :

N : Standard

Evacuation :

N : Chimney

V : SWV HGC-808 to HGC-1313

Relief valve :

1 : 150 Lbs (HGC-HW)

5 : 50 Lbs (HGC-AC)

9 : 90 Lbs (HGC-AC)

Ignition and gas type :

E : Electronic, natural

P : Constant, Propane (HGC-0404 to HGC-0909)

C : Constant, Natural

Heat exchanger :

AC : Steel

HW : Stainless steel

Capacity (Input) in thousands of BTU/h

0404 0505 0606

0707 0808 0909

1010 1111 1212

1313 1414 1515

Unit name :

HGC : Commercial Gas Hydronic

2) DESCRIPTIONS OF MAIN

COMPONENTS

2.1) Heat exchanger

The heat exchanger consists of ten (10) integral copper

finned tubes assembled between two (2) steel

manifolds. A double pass system is used. Standard

components used in conjunction with the exchanger

include a temperature/pressure gauge, a safety valve, a

temperature limiting device, a flow switch and a drain

valve.

2.2) Gas train

The gas train consists of a removable burner tray

assembly. Basically, the gas train incorporates a

combination gas control (valve and pressure regulator),

and a complete ignition system including a pilot.

2.3) Draft hood

All models use an integral type draft-hood that must be

used without alteration.

Loading...

Loading...