11

2.3.3) Intermittent hot surface ignition pilot

1. Turn the gas knob to the “ON” position. The glow

rod on the pilot should begin to heat and when hot

enough, allow the gas to flow to the pilot. Once all

air is expelled from the pilot line, the pilot should

light;

2. The glow rod should turn off and the main gas valve

open the gas to the main burners.

2.4) Verifications and adjustments

Once the main burners are in operation the following

points MUST

be checked.

2.4.1) Manifold pressure

Install a pressure gauge downstream from the gas valve

on the pressure tap provided on the vertical section of

the gas train pipe. The pressure observed after 5

minutes of operation should correspond to the value

specified in Table 3.

If your gas train is equipped with a modulating gas valve

make sure that this valve is not modulating when the

reading is being taken.

If you need to adjust the pressure, do so by turning the

main setting screw on the gas valve.

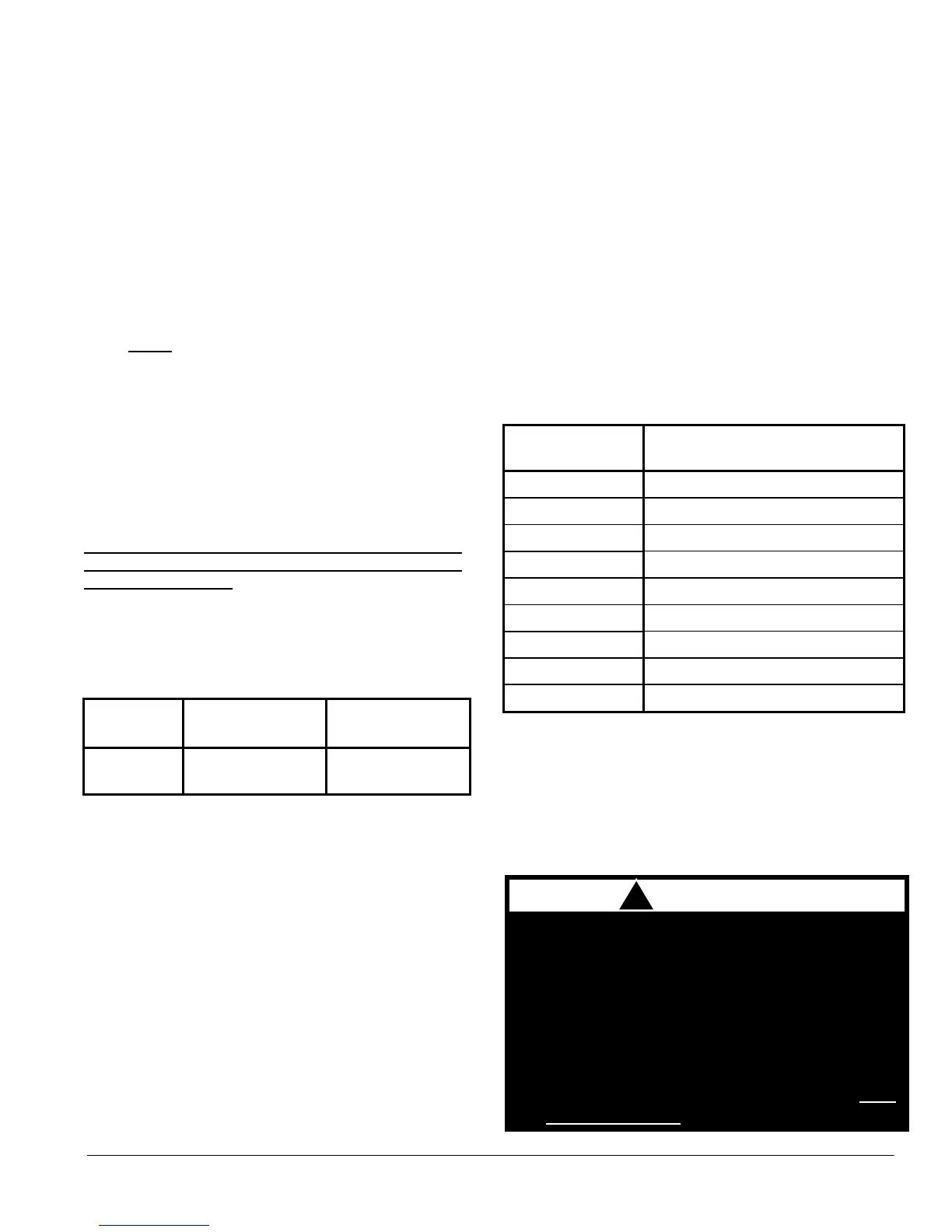

TABLE 3

Pressures Manifold

Models Pressure ("W.C.)

Natural Gas

Pression ("W.C.)

Propane Gas

HGRC 068

@ 340

3.5 10.0

2.4.2) Pilot control safety checks

Constantly burning pilot

1. Cut the gas supply by moving the gas valve knob to

“OFF”;

2. The valve must close in the following 90 seconds.

You should hear a little CLICK.

Intermittent pilots (electronic and hot surface)

1. Cut the gas supply by moving the gas valve knob to

“OFF”;

2. The control circuit should close the valve within 1

second.

2.4.3) Temperature control limit check

Adjust the temperature control limit below the present

water temperature. The gas supply to the burners

should stop immediately. Set the control for a higher

temperature and the burners should come on again.

2.4.4) Modulating valve (if used)

With the boiler running, turn the thermostatic valve knob

through its various positions. The gas flow to the

burners should decrease when the selected setting

point is reached. Consult Table 4 to select the correct

valve setting for your needs.

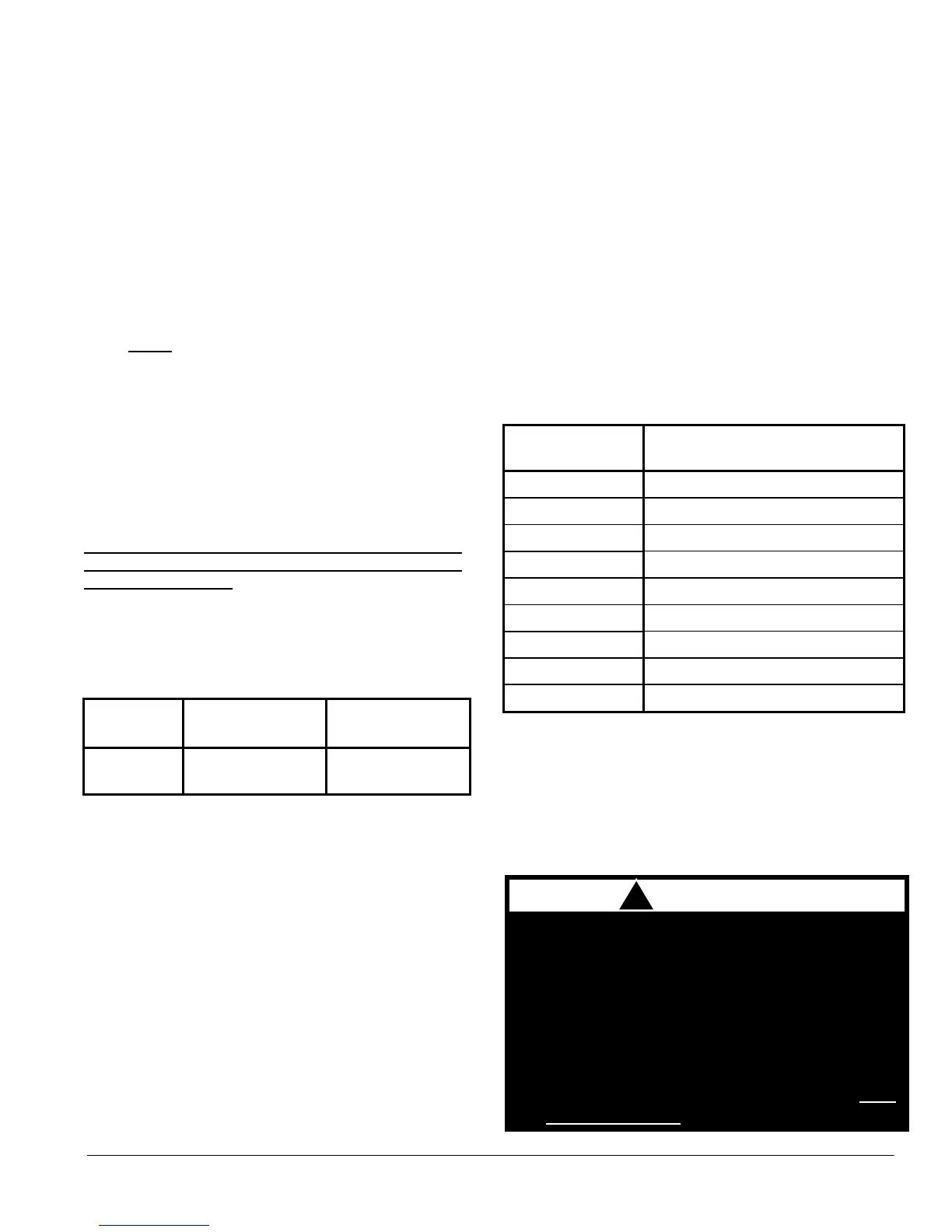

TABLE 4

Temperature modulation

Selector

position

Modulation temperature

o

F (

o

C)

1 49°C (120°F)

2 57°C (135°F)

3 66°C (150°F)

4 74°C (165°F)

5 82°C (180°F)

6 91°C (195°F)

7 99°C (210°F)

8 107°C (225°F)

9 116°C (240°F)

2.4.5) Gas leaks

Check the whole system for gas leaks after the

installation is completed. Use a solution of soap and

water on the pipe joints.

DANGER

If there is an major leak is detected or the

smell of gas is strong :

1. Open the windows,

2. Do not activate any electrical switches,

3. Extinguish all flames,

4. Immediately call your gas supplier from

another building.

Loading...

Loading...