10- ENG

D24152

Air Hammer

Blows Per Minute 4,500

Maximum Working Pressure 90 PSI

Air Inlet 1/4" NPT

Recommended Hose Size 3/8" I.D.

SPECIFICATIONS

Operation

Before each use:

l

Drain water from air compressor tank and condensation from air lines. See

air compressor’s operators manual.

Disconnect the tool from the air supply before

lubricating.

l

Lubricate tool, see “Maintenance” section in this manual.

l

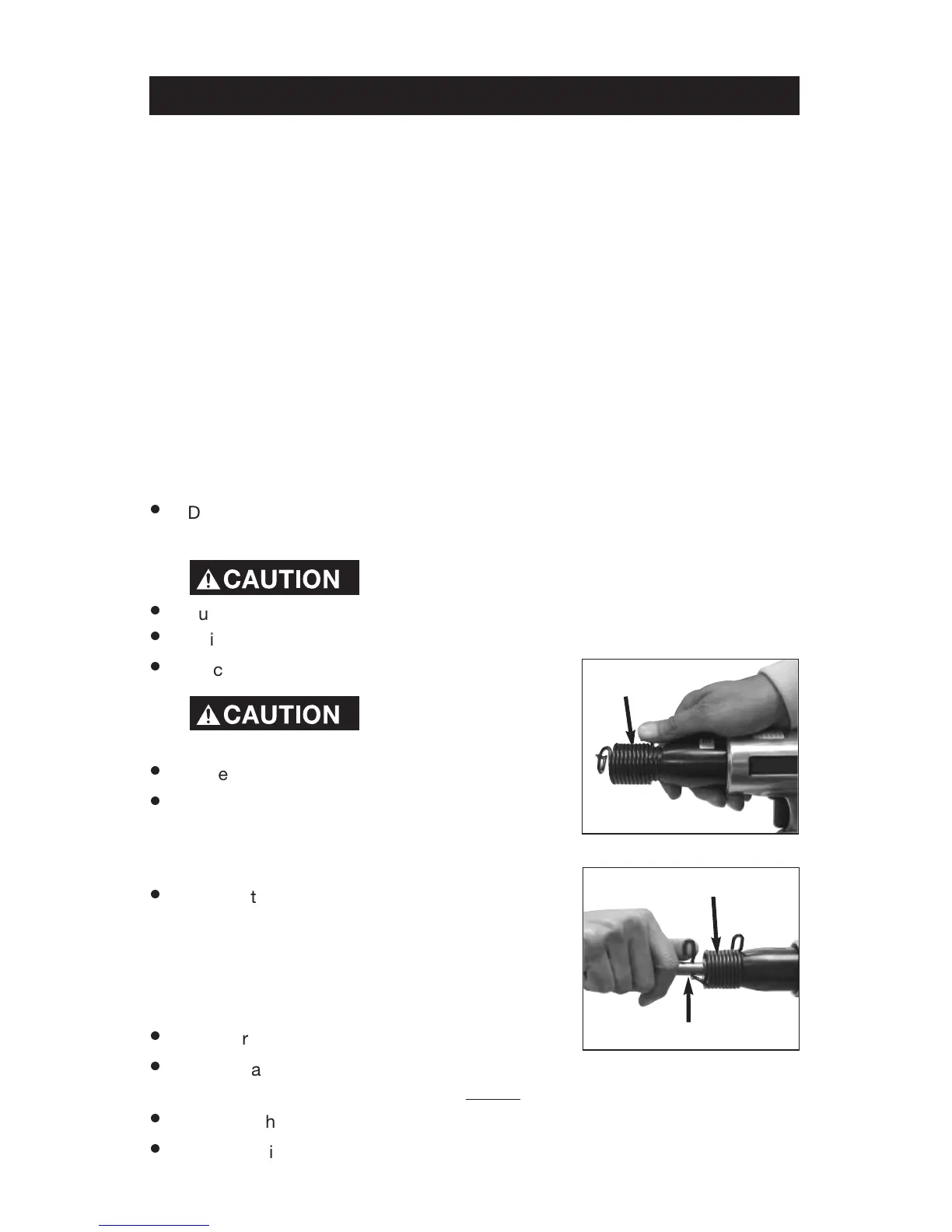

Using rear tab, as shown, remove spring retainer.

l

Place chisel into hammer.

Inspect chisel daily for

excessive wear or

cracks.

l

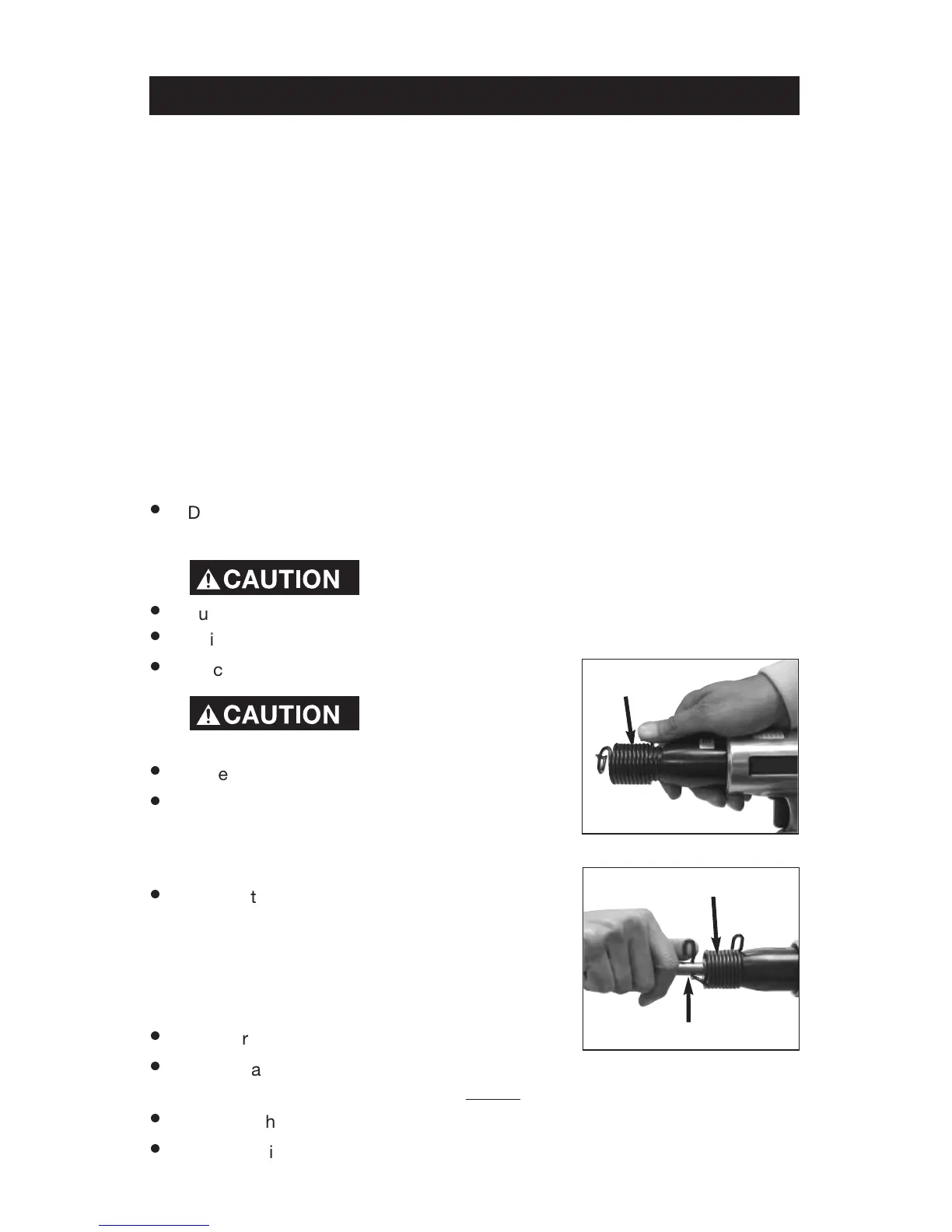

Slide spring retainer over chisel.

l

Using front tab, as shown, tightly install spring

retainer over chisel. IMPORTANT: The spring

retainer holds chisel in place. It must be secure

before the chisel can operate properly.

l

Connect tool to air hose of recommended size.

NOTE: The use of a quick connect set makes

connecting easier.

IMPORTANT: The use of air filters and air line

lubricators is recommended.

To use:

l

Turn air compressor on and allow air tank to fill.

l

Set the air compressor’s regulator to 90 PSI.

This tool operates at a maximum 90 PSI pressure.

l

Depress the trigger to operate tool.

l

Release trigger to stop tool.

ASSEMBLY

OPERATION

Retaining Spring

Retaining Spring

Remove

Install

Accessories Required

IMPORTANT: Line pressure or hose inside diameter should be increased to

compensate for unusually long air hoses (over 25 feet). Minimum hose diameter

should be 3/8” I.D. and fittings should have 1/4” NPT thread.

Loading...

Loading...