9- ENG

D24152

To use:

l

Turn air compressor on and allow air tank to fill.

l

Set the air compressor’s regulator to 90 PSI. This tool operates at a

maximum 90 PSI

pressure.

l

Place tool in forward or reverse position.

l

Depress the throttle control lever to operate tool. NOTE: The throttle

control lever provides instant response when depressed.

l

Release throttle control lever to stop tool.

l

Always disconnect air supply when changing sockets.

l

When job is complete, turn the air compressor off and store as described

in the air compressor operator manual.

Tips

l

Drive the fastener until the ratchet stalls and then further tighten by

operating the air ratchet in the same manner as a manually operated

ratchet.

MAINTENANCE

Lubrication

Air tools require lubrication throughout the life of the tool. The air motor and

bearing uses compressed air to power the tool. Because moisture in

compressed air will rust the air motor, you must lubricate the motor daily. An

inline oiler is recommended.

To lubricate the air motor manually:

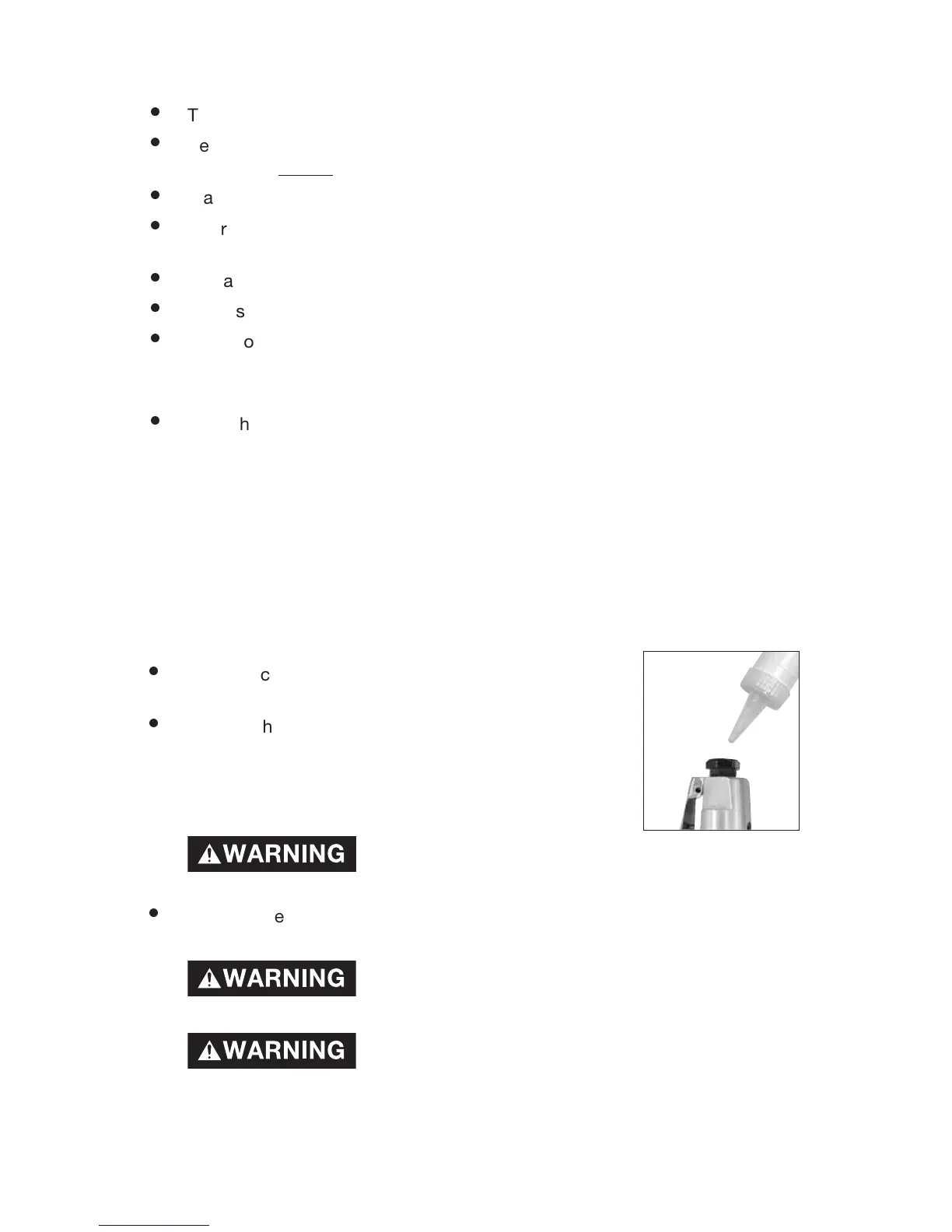

l

Disconnect the tool from the air supply holding it so the

air inlet faces up.

l

Depress throttle control lever and place one to two

drops of air tool oil in the air inlet Depressing the

throttle control lever helps circulate oil in the motor.

NOTE: Use SAE #10 weight oil if air tool oil is not

available.

Keep out of the reach of children. If taken

internally, do not induce vomiting, call a

doctor immediately or contact your local poison control center.

l

Connect the tool to an air source, cover the exhaust end with a towel and

run for a few seconds.

Any excess oil in the motor is immediately

expelled from the exhaust port. Always direct

exhaust port away from people or objects.

Failure to lubricate the tool at the air inlet will

void your warranty.

Loading...

Loading...