10

FIG. E

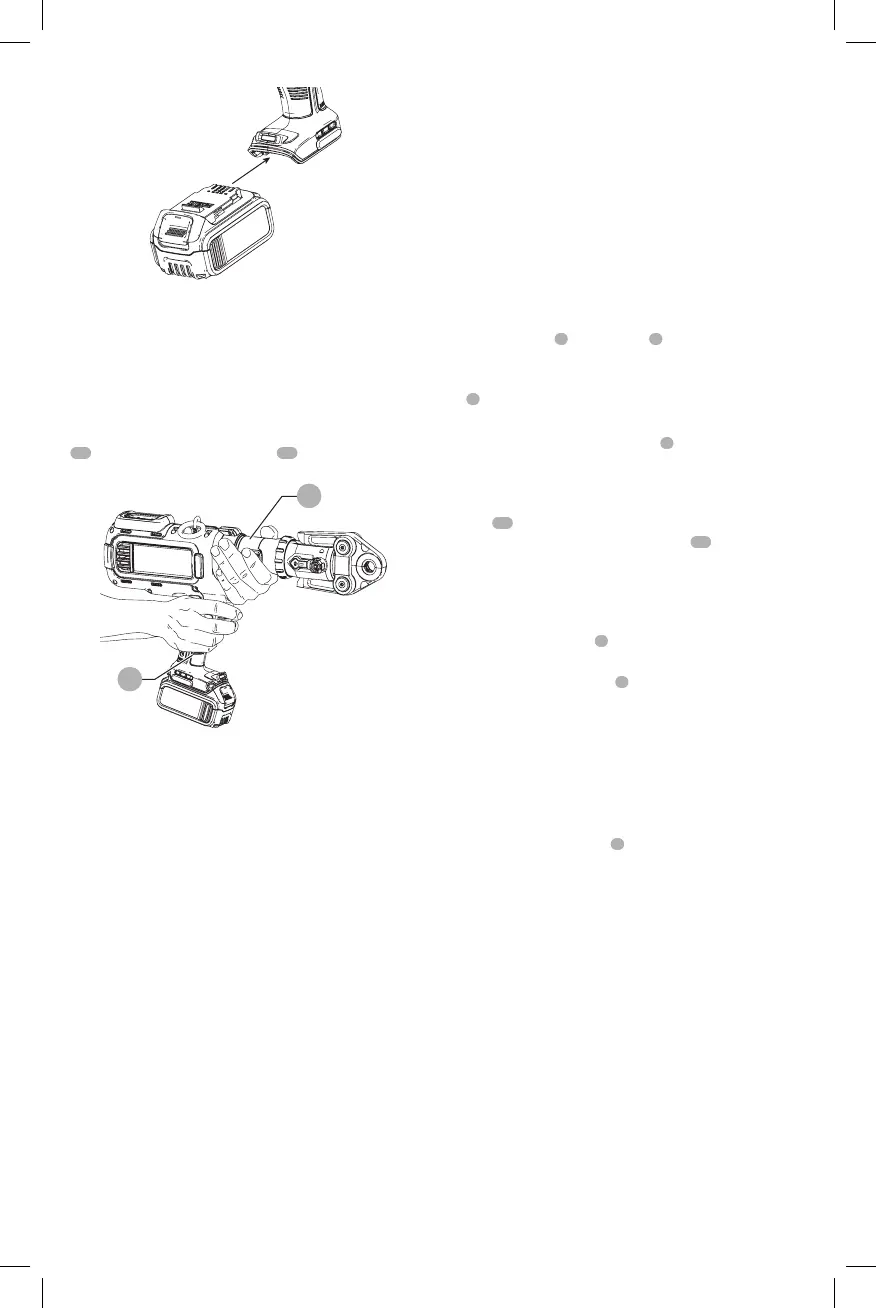

Proper Hand Position (Fig. F)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal injury,

ALWAYS hold securely in anticipation of a sudden

reaction.

Proper hand position requires one hand on the main handle

15

and one hand on the tool neck

16

, of the press tool.

FIG. F

15

16

Preparing the Connection

WARNING: Always follow the specific

manufacturer's installation instructions for press

tool attachments being used. It is the installer's

responsibility to ensure the compatibility of the pipe

and fittings used for the connection. Contact the

manufacturer for specific information on their fittings

system. Failure to follow all instructions and warnings

may result in property damage and/or serious

personalinjury.

• Make sure to clear the work area of loose debris and any

other items that could hinder the pressing operation.

• Always ensure the work area is set up properly and that

the tool's connection is prepared according to the fitting

manufacturer’s instructions.

• Follow the fitting manufacturer’s instructions to make

sure the tubing is inserted properly into the fitting.

Pressing (Fig. A, C)

WARNING: To reduce the risk of serious personal

injury, inspect the jaw assembly for cleanliness,

cracks or other damage before beginning a press.

Using a dirty or damaged jaw assembly could result

in improper press connections that could lead to

extensive property damage. Return damaged jaw

assembly to a

service facility.

WARNING: To reduce the risk of serious personal

injury, prior to use, inspect workpieces for cracks,

defects or wear. Defective workpieces may shatter.

WARNING: Before turning on the press tool, be

sure hands are clear of the jaws.

Before beginning a press, check the fuel gauge to determine

whether the battery charge is sufficient to complete the

pressing operation.

NOTE: The tool will turn off automatically after 2 minutes

of no use.

1. Press jaw arms

2

to open jaws

1

and place around

thefitting.

2. Turn the tool ON by holding the power ON/OFF button

8

until all 3 LEDs illuminate green.

3. Hold tool securely.

4. Press and hold the trigger switch

5

(bottom trigger)

until the cycle is complete, indicated by the ram

automatically returning to its original position.

5. When the press cycle is complete, the Cycle Complete

LED

18

will flash green for 5 seconds. If the press cycle

is incomplete, the cycle complete LED

18

will flash red

for 5 seconds. No action is possible until the user presses

the ON/OFF button.

6. If the battery dies or tool malfunctions during the press

connection, the rollers can retract by pressing the

reverse trigger switch

6

. This will retract the ram and

allow the jaws to be opened.

7. Press the ON/OFF button

8

to turn the tool OFF, then

press the jaw arms to open the jaw set.

NOTE: If the tool does not complete the press properly, read

the Troubleshooting Guide or LED Indications sections or

take the tool to a

factory service center.

NOTE: When pressing overhead, always confirm workpiece

and tool are secure before pressing.

NOTICE: In the event of an incomplete press, press the

reverse trigger switch

6

to open the press jaws and

remove the material.

Inspecting the Pressed Connection

1. Clear the pressed fitting of any control rings or control

labels. These are used by fitting manufacturers to

indicate an unpressed fitting.

2. Check for excessive misalignment, tubing not fully

inserted into the fitting, and incorrect jaw or attachment

alignment. Make sure no other issues are present on the

pressed connection per the manufacturer’s instructions.

If any issues are present, remove the fitting and replace

with a new one.

3. Test the fitting according to manufacturer’s instructions

or local codes.

MAINTENANCE

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

Loading...

Loading...