14

ENGLISH

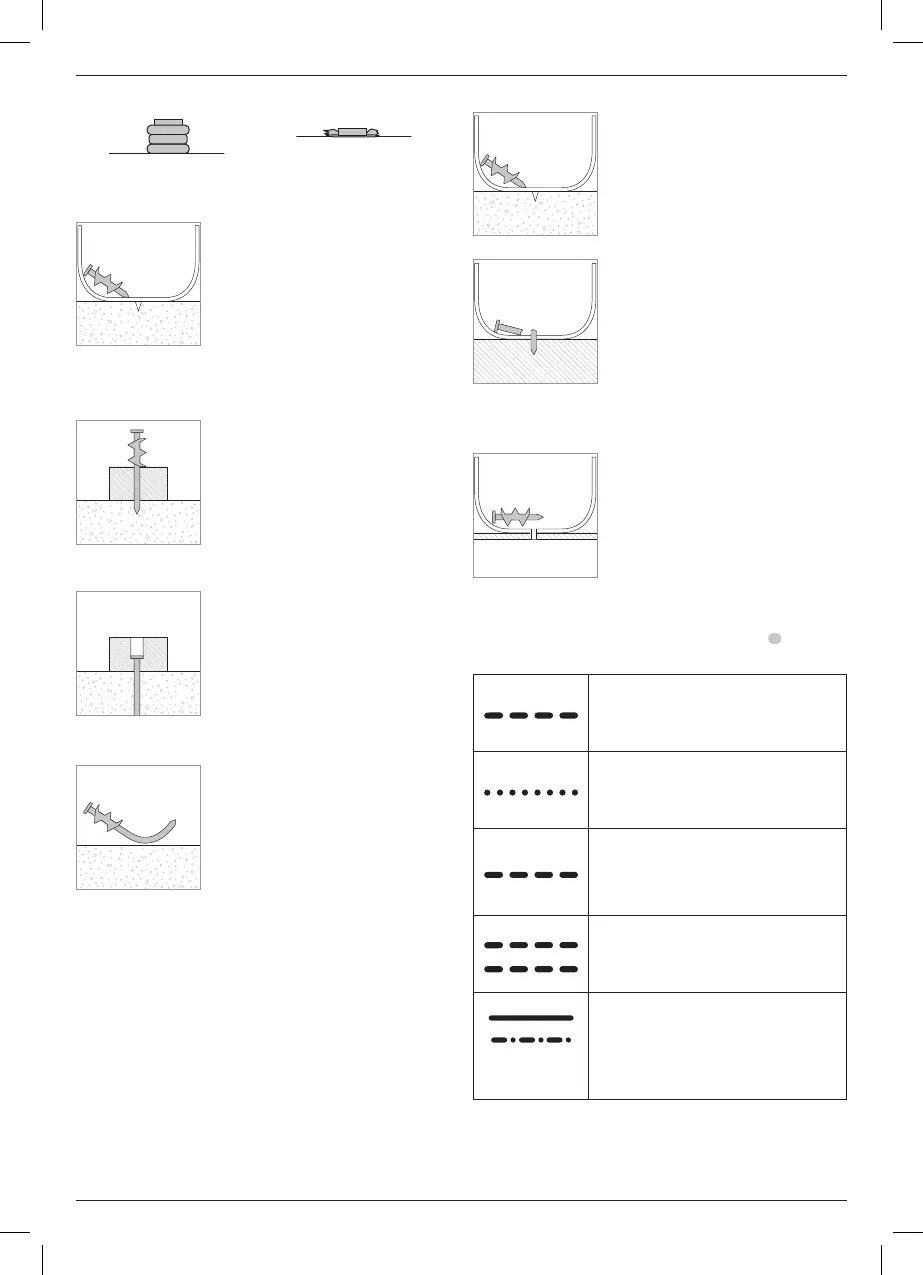

Pin/Fastener Troubleshooting

Properly driven pin Over driven pin

CONCRETE

Pin does not hold in the concrete.

Cause:

- Too hard/high strength

concrete

- Hard or large aggregate

inconcrete

Action:

- Use shorter pin.

- Switch to higher speed setting.

Pin does not drive deep enough.

Cause:

- Pin too long

- Speed setting too low

Action:

- Use shorter pin.

- Switch to higher speed setting.

Pin drives too deep.

Cause:

- Pin too short for application

- Speed setting too high

Action:

- Use longer pin.

- Switch to lower speed setting.

Pin bends.

Cause:

- Pin hit large aggregate on entry

- Too hard/high strength

concrete

- Pit hit rebar just under surface

Action:

- Use shorter pin.

- Make sure nailer is

perpendicular to the work

surface.

- Move 8 cm and tryagain.

STEEL

Pin does not penetrate the surface.

Cause:

- Speed setting too low

- Material to hard for pin type

Action:

- Increase tool speed setting

Pin breaks or bends.

Cause:

- Pin too long

- Speed setting too low

- Material to hard for pin type

Action:

- Use shorter pin.

- Switch to higher speed setting.

Pin does not hold in the steel.

Cause:

- Steel base material too thin

Action:

- Use alternative means to secure

base material.

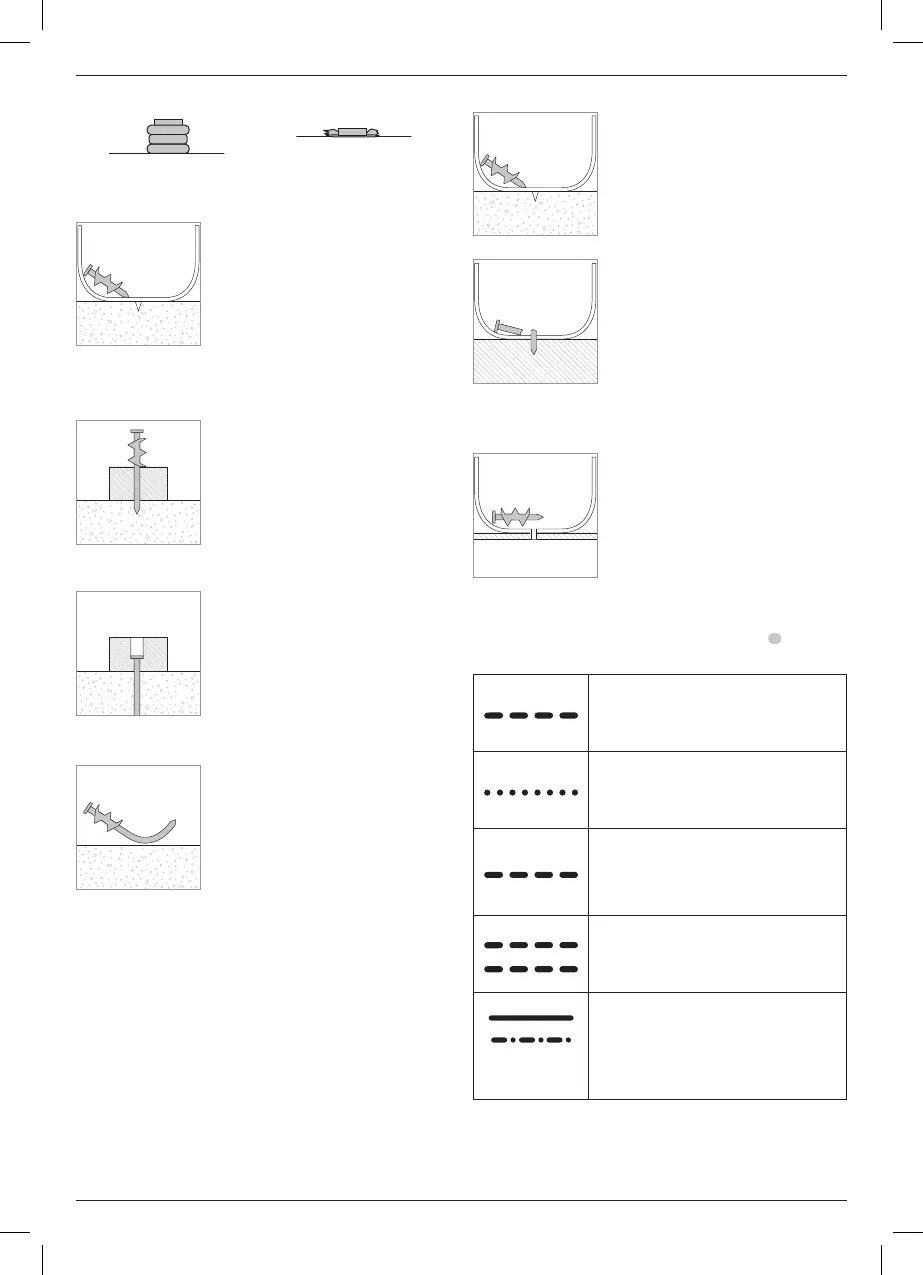

Headlights/LED Indicator (Fig. A)

There are low battery and jam/stall indicator lights

9

located on

the front of the tool on each side of the magazine.

LOW BATTERY

Replace battery with a charged pack.

HOT PACK

Let the battery cool or replace it with a

cool pack.

JAM/STALL CONDITION

Rotate the stall release lever to release.

Refer to Stall Release or Clearing a

Jammed Pin.

HOT TOOL (Both LEDs Flashing)

Let the tool cool down before continuing

use.

or any other

combination.

ERROR

Reset tool by removing and reinserting

battery pack or cycling trigger lock off.

If error code persist, take tool to an

authorised

service center.

Loading...

Loading...