19

5. USE OF DULL OR DIRTY BLADES

Dull blades cause increased loading of the saw. To compensate, an operator will

usually push harder which further loads the unit and promotes twisting of the blade

in the kerf. Worn blades may also have insufficient body clearance which increases

the chance of binding and increased loading.

6. LIFTING THE SAW WHEN MAKING BEVEL CUTS

Bevel cuts require special operator attention to proper cutting techniques –

especially guidance of the saw. Both blade angle to the shoe and greater blade

surface in the material increase the chance for binding and misalignment (twist) to

occur.

7. RESTARTING A CUT WITH THE BLADE TEETH JAMMED

AGAINST THE MATERIAL.

The saw should be brought up to full operating speed before starting a cut or

restarting a cut after the unit has been stopped with the blade in the kerf. Failure to

do so can cause stalling and kickback.

CUTTING

Support the work so that the cut will be on your right. Place the wider portion of the

saw shoe on that part of the work piece which is solidly supported, not on the

section that will fall off when the cut is made. As examples, Figure E14 illustrates the

CORRECT way to cut off the end of a board, and Figure E15 the WRONG way. Always

clamp work. Don’t try to hold short pieces by hand! Remember to support

cantilevered and overhanging material. Use caution when sawing material from

below.

Be sure saw is up to full speed before blade contacts material to be cut. Starting

saw with blade against material to be cut or pushed forward into kerf can result in

kickback.

Push the saw forward at a speed which allows the blade to cut without labouring.

Hardness and toughness can vary even in the same piece of material, and knotting

or damp sections can put a heavy load on the saw. When this happens, push the

saw more slowly, but hard enough to keep it working without much decrease in

speed.

Forcing the saw can cause rough cuts, inaccuracy, kickback and over-heating of the

motor.

Should your cut begin to go off the line, don’t try to force it back on. Release the

switch and allow blade to come to a complete stop. Then you can withdraw the saw,

sight anew, and start a new cut slightly inside the wrong one. In any event, withdraw

the saw if you must shift the cut. Forcing a correction inside the cut can stall the saw

and lead to kickback. IF SAW STALLS, RELEASE THE TRIGGER AND

BACK THE SAW UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN

THE CUT AND CLEAR OFF THE EDGE BEFORE RESTARTING.

As you finish a cut, release the trigger and allow the blade to stop before lifting the

saw from the work. As you lift the saw, the spring-tensioned telescoping guard will

automatically close under the blade. Remember the blade is exposed until this

occurs, never reach under the work for any reason whatsoever. When you have to

retract the telescoping guard manually (as is necessary for starting pocket cuts)

always use the retracting lever.

NOTE: When cutting thin strips, be careful to ensure that small cutoff pieces don’t

hang up on inside of lower guard.

When ripping (cutting with the grain) the use of a rip fence is recommended.

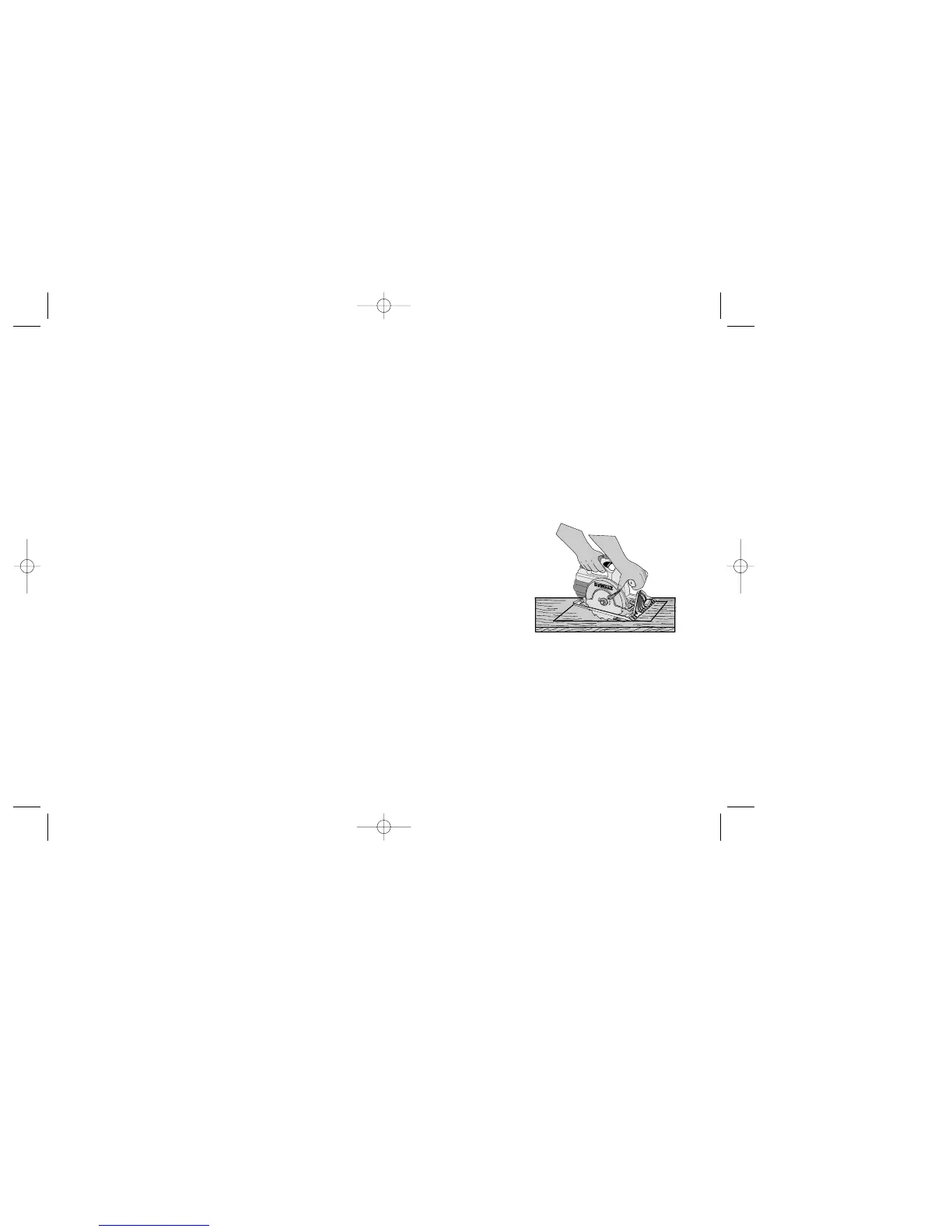

POCKET CUTTING

DISCONNECT TOOL FROM

BATTERY PACK WHEN MAKING

THIS OR ANY OTHER

ADJUSTMENT.

Adjust saw shoe so blade cuts at

desired depth. Tilt saw forward and rest

front of the shoe on material to be cut.

Using the retracting lever, retract blade

guard to an open position. Lower rear of

shoe until blade teeth almost touch

cutting line. Now release the blade

guard (its contact with the work will

keep it in position to open freely as you

start the cut) (Figure E16). Start the motor

and gradually lower the saw until its shoe rests flat on the material to be cut.

Advance saw along the cutting line until cut is completed. Release trigger and allow

blade to stop completely before withdrawing the blade from the material. When

starting each new cut, repeat as above. Never tie the blade guard in a raised

position.

E16

Loading...

Loading...