7

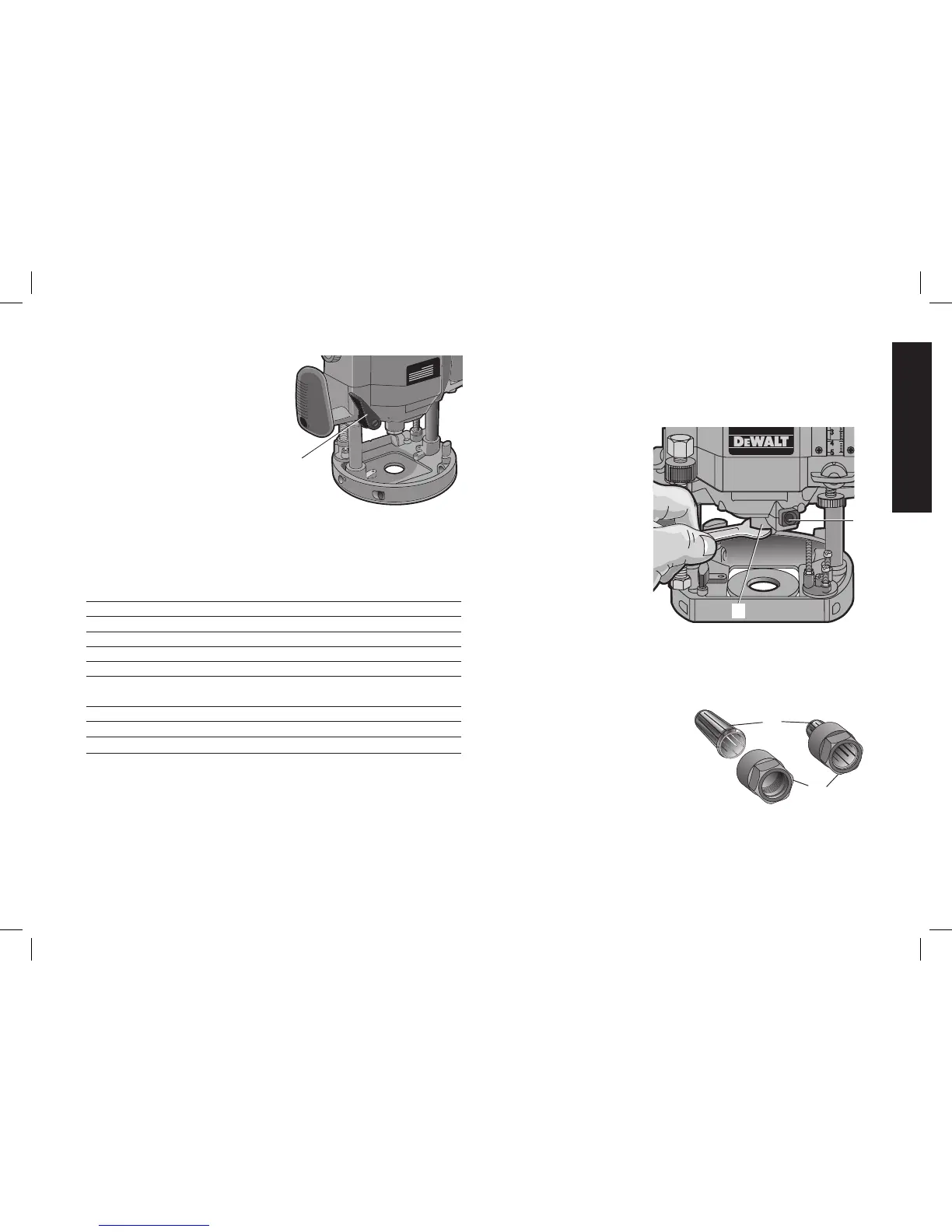

NOTE: Before installing a

E

FIG. 2

router bit in your unit,

position the tool so that the

collet is easily accessible. To

do this, rotate the height

stop thumb wheel (C),

shown, counterclockwise

until it is about 1/2" (13mm)

from the top of the threaded

height stop rod (D). Raise

the plunge lock lever (E),

shown in Figure 2, and let

the router rise to its full height. Depress the plunge release lever to

lock the tool in place.

TECHNICAL DATA

Model DW625

Voltage 120

Speed 8,000 – 20,000 rpm

Insulation double insulated

Column spring loaded twin column

Plunging stroke 2-3/4" (70 mm)

Routing depth 0-70 mm adjustable

Cutter mounting precision collet, size

1/4" (6.4mm) and 1/2" (13mm)

Cutter cap max. 2-3/8" (60 mm)

Routing (shallow)

Rotary depth stop 3 stage depth position

Controls

NOTE: Before operating any of the controls, read this whole

section.

PLUNGE LOCK LEVER (FIG. 2)

The plunge lock lever (E) allows the router bit to be plunged directly

into the workpiece. Simply raise the plunge lock lever when you

want to lower the router into the work, as shown. You can lower

the unit until it reaches your preset stop. To lock the tool in place

anywhere along its vertical travel, depress the lever.

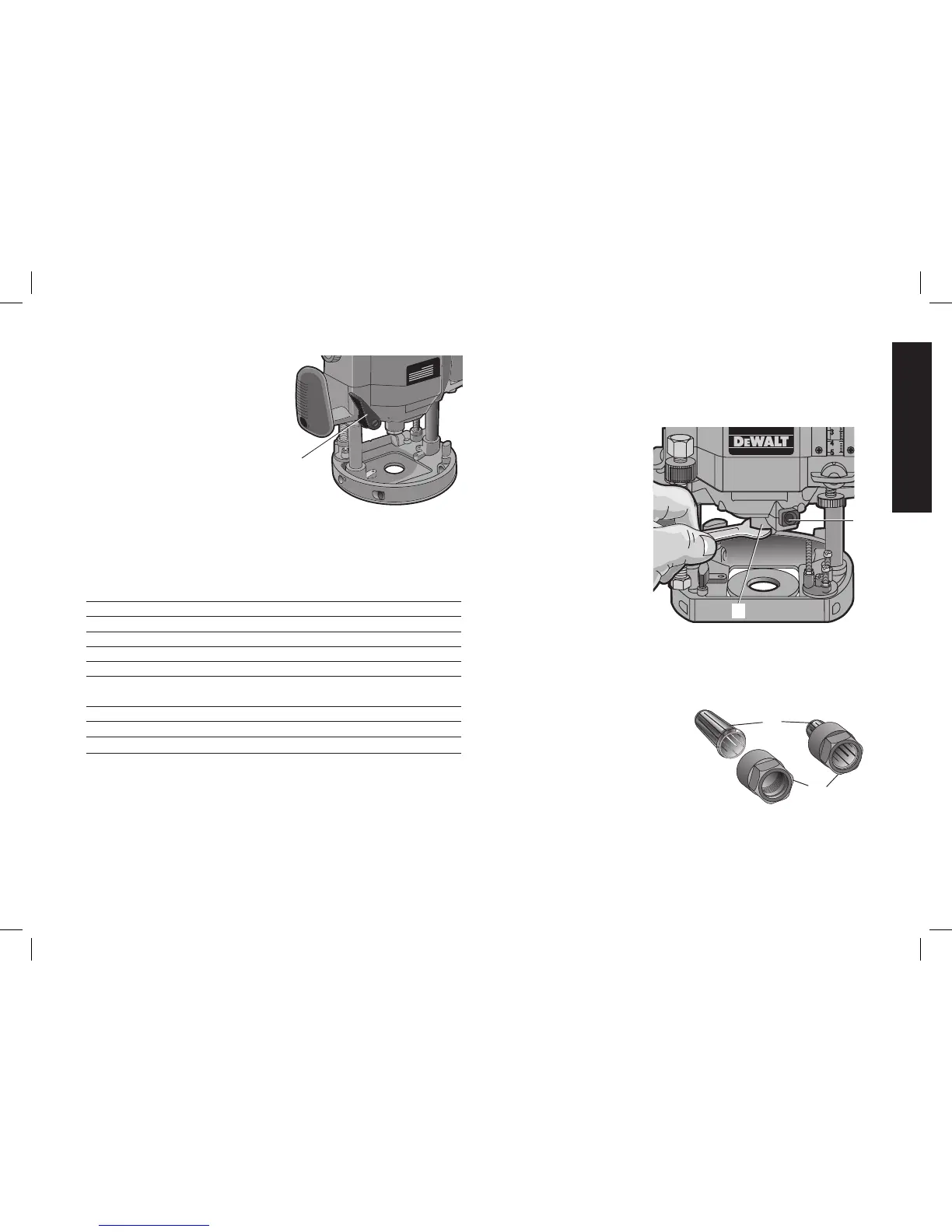

BIT INSTALLATION AND REMOVAL (FIG. 3, 4)

IMPORTANT NOTE:

FIG. 3

H

I

Always snap the collet (I)

firmly into the collet nut

(G), (past the retainer

spring) before installing a

bit.

Use the supplied wrench

and the spindle lock

button (H) as necessary to

loosen (counterclockwise)

the collet nut, as shown.

Insert the round shank of

the desired router bit into

the loosened collet as far

as it will go and then pull

it out about 1/16" (1.6 mm).

Hold the spindle shaft by depressing the spindle lock button while

firmly tightening the collet nut with the wrench.

Your router has a unique locking

FIG. 4

I

G

system for retaining the bit. When

removing a bit, the collet nut must

be loosened with the wrench. The

collet nut will turn approximately

3/4 of a turn and then become

tight again. At this point the bit

can’t be removed. Using the same

procedure, loosen the nut a

second time.This lifts the collet and

makes it very easy to remove the

bit.

Loading...

Loading...