ENGLISH

6

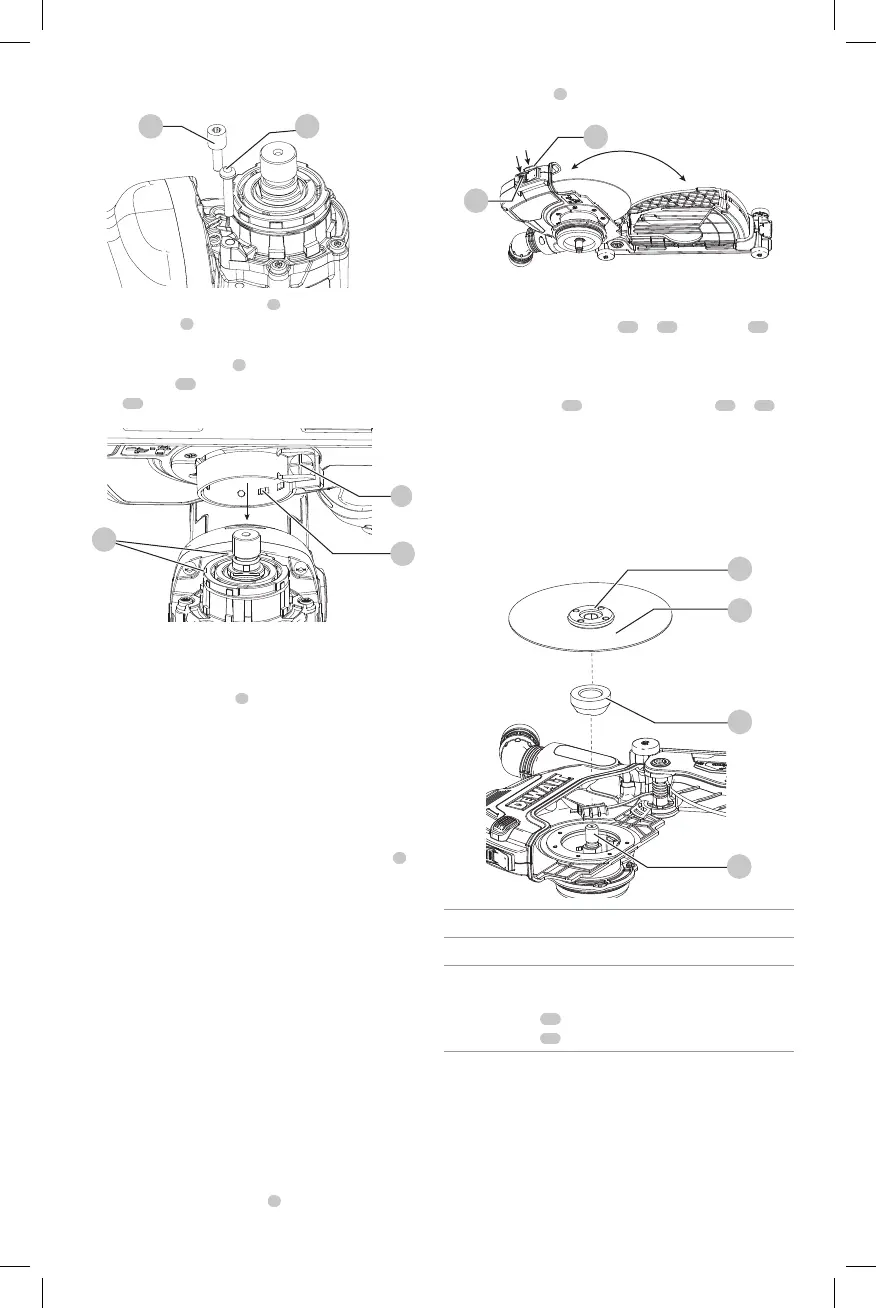

Fig. C

18 19

3. Press the front shroud button

7

and the side

shroud button

8

at the same time to fully open the

cuttingshroud.

4. Loosen the collar screw

2

on the cutting shroud and

align the tabs

20

on the cutting shroud with the

slots

21

on the grinder gearcase.

Fig. D

20

2

21

5. Rotate the shroud into the desired working position. The

shroud should be positioned between the spindle and

the operator to provide optimumefficiency.

6. Tighten the collar screw

2

to secure the cutting shroud

on the gear case. Do not operate the grinder with a

loose cuttingshroud.

7. To remove the cutting shroud, loosen the collar screw,

rotate the cutting shroud to align the slots and tabs and

pull up on the cuttingshroud.

NOTE: The cutting shroud is pre-adjusted to the diameter of

the gear case hub at the factory. If, after a period of time, the

cutting shroud becomes loose, tighten the collar screw

2

.

Only adjust the collar screw when it is on the grinder

otherwise the collar can bedamaged.

NOTICE: If cutting shroud cannot be secured by

tightening the collar screw, do not use tool. Take the

tool and cutting shroud to a service center to repair or

replace the cuttingshroud.

Mounting and Using Type 1 (Cutting)

Diamond Wheels (Fig.A, E, F)

WARNING: Only Type 1 Diamond Wheels shall be

used with cutting shroud. Do not cut metal. Do not

use with bonded abrasivewheels.

CAUTION: Do not use the shroud with the grinder

flanges. Only use the shroud with the flanges provided

withit.

1. With the cutting shroud attached to the grinder,

press the front shroud button

7

and the side

shroud button

8

at the same time to fully open the

cuttingshroud.

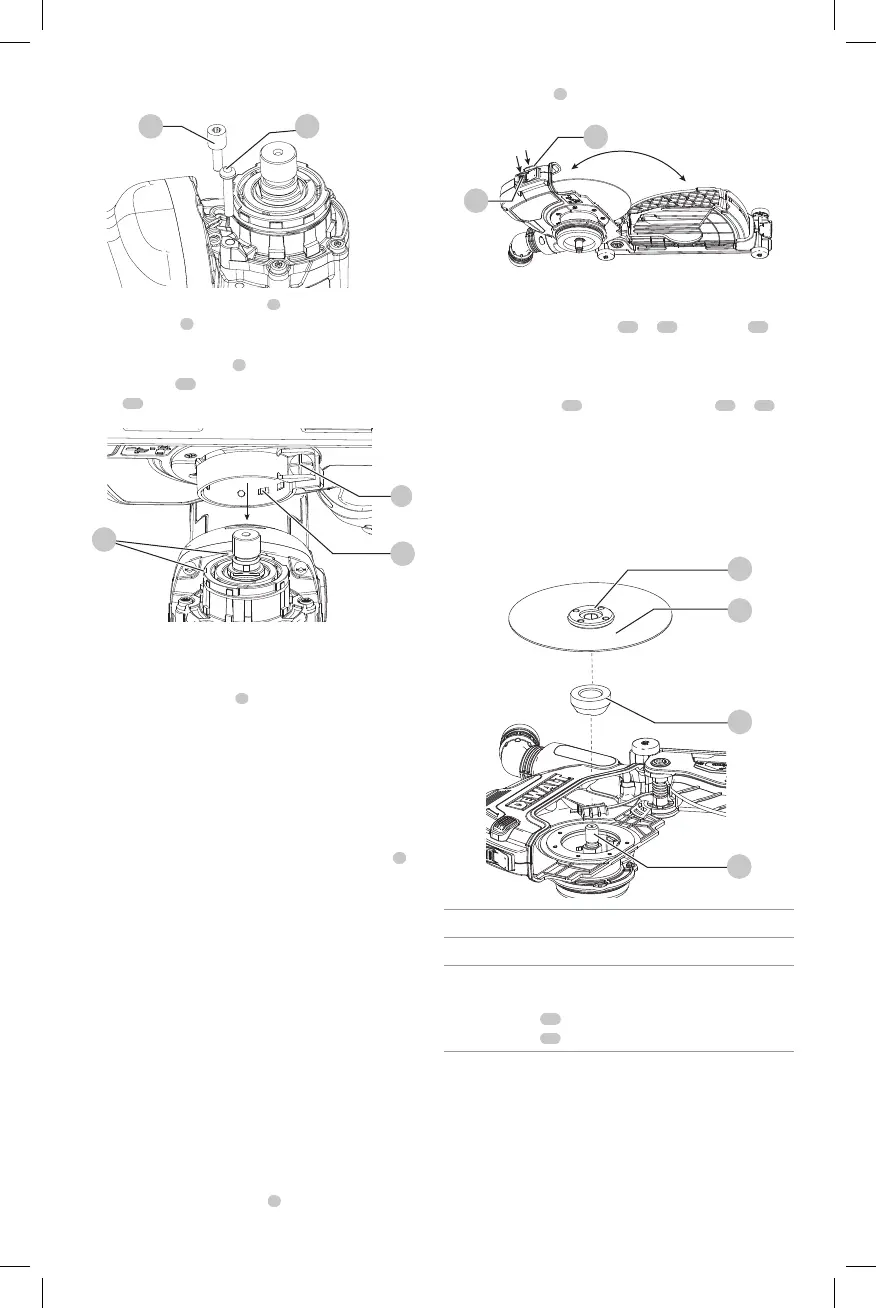

Fig. E

8

7

2. Remove the backing flange that is on the grinder (and

keep it for conversion back to agrinder).

3. Install the backing flange,

12

or

14

, on spindle

25

.

IMPORTANT: The DWE46125 comes with two sets of

flanges. Refer to the Flange/Grinder Compatibility

Chart at the end of this section for properuse.

4. Place the wheel

24

on the locking flange

11

or

13

,

and place both on the spindle, against the backing

flange, centering the wheel on the raised center of the

backingflange.

5. While depressing the spindle lock button, tighten the

locking flange using awrench.

6. To remove the wheel, depress the spindle lock button

and loosen the lockingflange.

Fig. F

11

12

24

25

Flange / Grinder Compatibility Chart

Flange set Grinder

Short (silver)

flange set:

Locking flange

11

Backing flange

12

DCG413

Loading...

Loading...