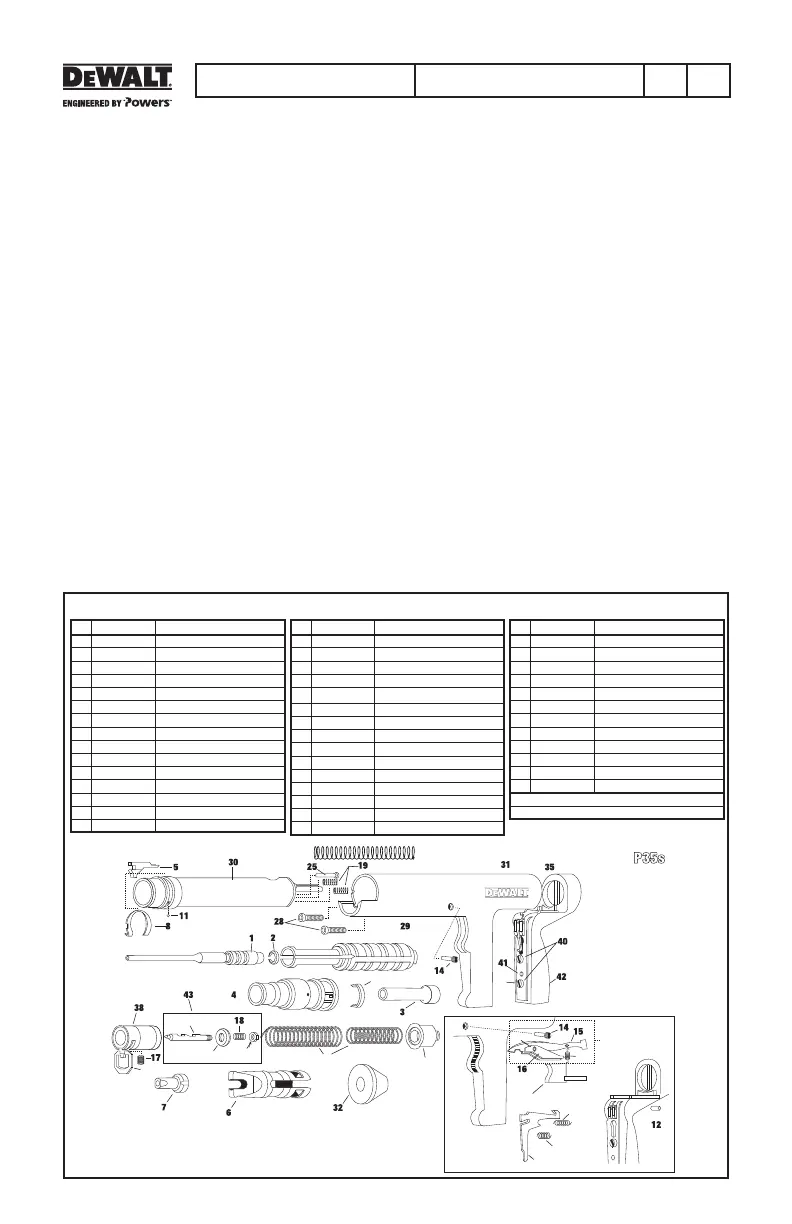

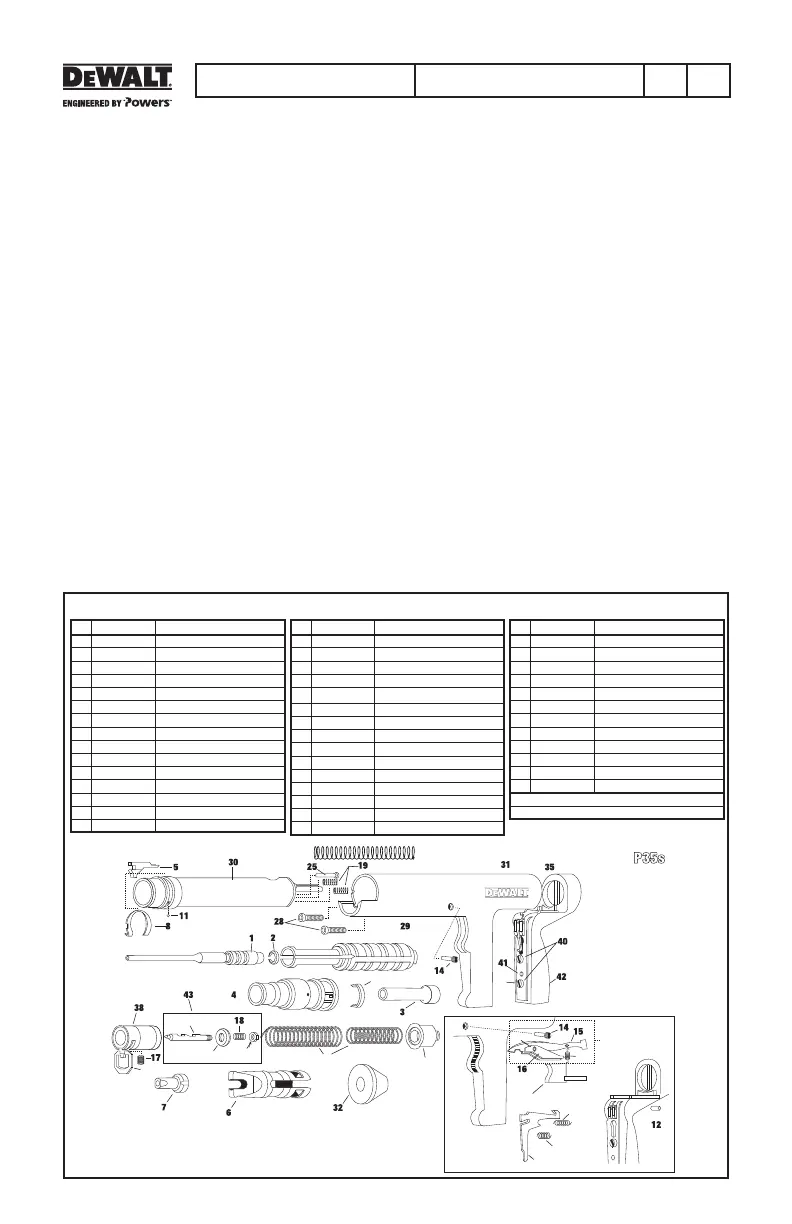

P35s

EN

10

P35s SPARE PARTS LISTING

PROPER MAINTENANCE AND CLEANING

MAKE SURE THE TOOL IS NOT LOADED. BE SURE THE TOOL IS NOT HOT PRIOR TO ATTEMPTING

DISASSEMBLY OR CLEANING.

DAILY FUNCTION TEST

Check the functioning of the tool, without a powder load or fastener in the tool, by pushing down against

the work surface, pulling the trigger, and releasing the tool from the work surface. Function the unloaded

tool several times and insure that the breech parts and firing mechanism operate freely before fastening

with the tool.

Your DEWALT Authorized representative should be asked to assist the first time you disassemble and

clean your tool. If you ever have any trouble reassembling the tool, or have any doubt about worn parts, call

your DEWALT Authorized Powder Distributor.

CLEANING

AIl parts should be cleaned with detergent oil and the wire brushes supplied with your tool kit. Remove heavy

dirt build-up with the brush. After cleaning with oil, all parts should be wiped thoroughly dry. Excess oil will

tend to collect dirt and dust. Wear eye protection when cleaning the tool. The piston rod, barrel assembly,

and receiver should all be cleaned of excess dirt on a daily basis. Check the condition of the piston for

damage from wear and deformation.

To maintain this tool in good working condition, it is necessary to disas semble and clean the entire tool if

dirt is evident in the breech face, or if the tool appears to lose power. All parts should be cleaned with oil and

wire brushes. Remove heavy dirt. All parts should be wiped thoroughly dry after cleaning with oil.

General tool mainte nance should be performed at six month intervals or more frequently as required by the

frequency of tool use.

23

39

27

22

21

24

24

37

20

9

26

36

33

LEVER

GUIDE 13

KIT

33

# DESCRIPTION

1 52200-PWR Piston W/Ring 21/SDF-Standard

2 52106-PWR Piston Ring

3 52204-PWR Guide 21/F3-1Full Size

4 52206-PWR Baseplate 21/SI Full Size

5 52208-PWR Piston Stop

6 52210-PWR Baseplate 21/S2 Limited Access

7 52212-PWR Guide 21/F-2-1Limited Access

8 52214-PWR Annular Spring

9 52118-PWR Trigger

10 52120-PWR Shear Clip

11 52122-PWR Steel Annular Ball

12 52124-PWR Release Lever Pin

13 52126-PWR Lever Guide Kit

†

14 52128-PWR Threaded Pin

15 52130-PWR Advance Lever

# DESCRIPTION

16 52132-PWR Advance Lever Guide

17 52134-PWR Sear Spring

18 52138-PWR Firing Pin Return Spring

19 52140-PWR Strip Pressure Ball & Spring

20 52142-PWR

Advance Lever Spring

21 52144-PWR Rear Spring Kit

22 52146-PWR Sear

23 52148-PWR Firing Pin

24 52150-PWR End Cap

25 52152-PWR Pressure Pin

26 52154-PWR Compression Spring

27 52156-PWR Firing Pin Nut

28 52158-PWR Front Allen Cap Screw (2)

29 52216-PWR Piston Guide

30 52218-PWR Steel Liner Assembly

# DESCRIPTION

31 52220-PWR Trigger Return Spring

32 52222-PWR Housing

33 52168-PWR Support Strip Assembly

34 52170-PWR Release Lever

35 52172-PWR Retaining Ring

36 52174-PWR Trigger Return Spring

37 52176-PWR Advance Lever Bushing

39 52180-PWR Spring Detent (2)

40 52182-PWR Cheese Head Screw (2)

41 52184-PWR Handle Allen Screw

42 52186-PWR Rubber Grip

43 52181-PWR Firing Pin Assembly

*

* Firing Pin Assembly Includes Items #18, 23, 27 & 39

†

Lever Guide Kit Includes Items # 14, 15, 16, 20 & 39

Loading...

Loading...