P35s

EN

3

Washer

Stop

Spall

CAT # DESCRIPTION CTN

50065

-PWR

6’ (1.8m) Di-electric Pole Tool 1

50066

-PWR

8’ (2.44m) Di-electric Pole Tool 1

FASTENER FUNCTIONING

Prior to learning the safe operating procedures for this tool, it is important to understand

how a powder actuated fastener works. A powder actuated fastener is considered to be

a direct drive or forced entry type of fastener because it is driven directly into the base

material. The driving action causes tremendous forces to be applied to the fastener.

DEWALT powder actuated fasteners are specially designed and manufactured to

withstand the forces imposed during the driving operation. Only fasteners manufactured

or supplied by DEWALT should be used in this tool.

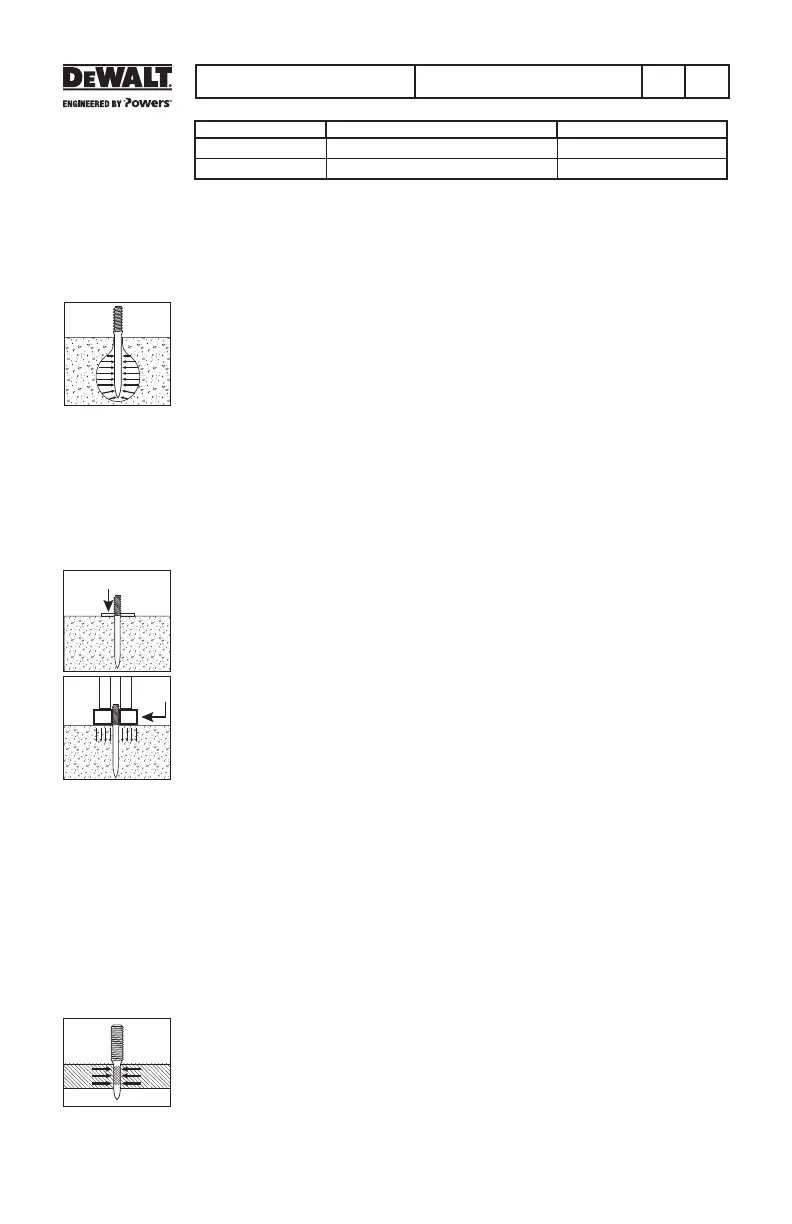

FUNCTIONING IN CONCRETE

The performance of a powder actuated fastener when installed into concrete or

masonry base materials is based on the following factors:

1. Strength of the base material

2. Hardness and concentration of the aggregate

3. Shank diameter of the fastener

4. Depth of embedment into the base material

5. Fastener spacing and edge distance

In addition to these factors, installation tool accessories such as a stop spall, which

reduces the tendency of the concrete surface to spall during the driving action, can

increase the performance of the fastener.

When a powder actuated fastener is driven into concrete, it displaces the volume of

concrete around the embedded area of the fastener shank. As this occurs, the concrete

directly surrounding the fastener is compressed and in turn presses back against the

shank of the fastener. Additionally, the driving action generates heat which causes

particles within the concrete to fuse to the shank of the fastener. This combination

of compression and fusion holds the fastener in the concrete base material. A similar

action occurs when fastening into block masonry.

Generally, the performance of the fastener in a given concrete strength will increase

with greater embedment depths in a certain range. Depending on the fastener style

and base material strength, embedment depths range from 5/8" to 1-1/2". For depths

greater than this range, there is the possibility of fastener bending or fishhooking which

may decrease expected load capacities and create a safety hazard.

During the driving action, some localized surface spalling of the concrete may occur.

Normally, this is a surface effect which does not effect the performance of the fastener.

However, it may pose an aesthetic problem for exposed applications where a fixture is

not used. In cases such as this, two methods can be used to improve the appearance

of the fastener.

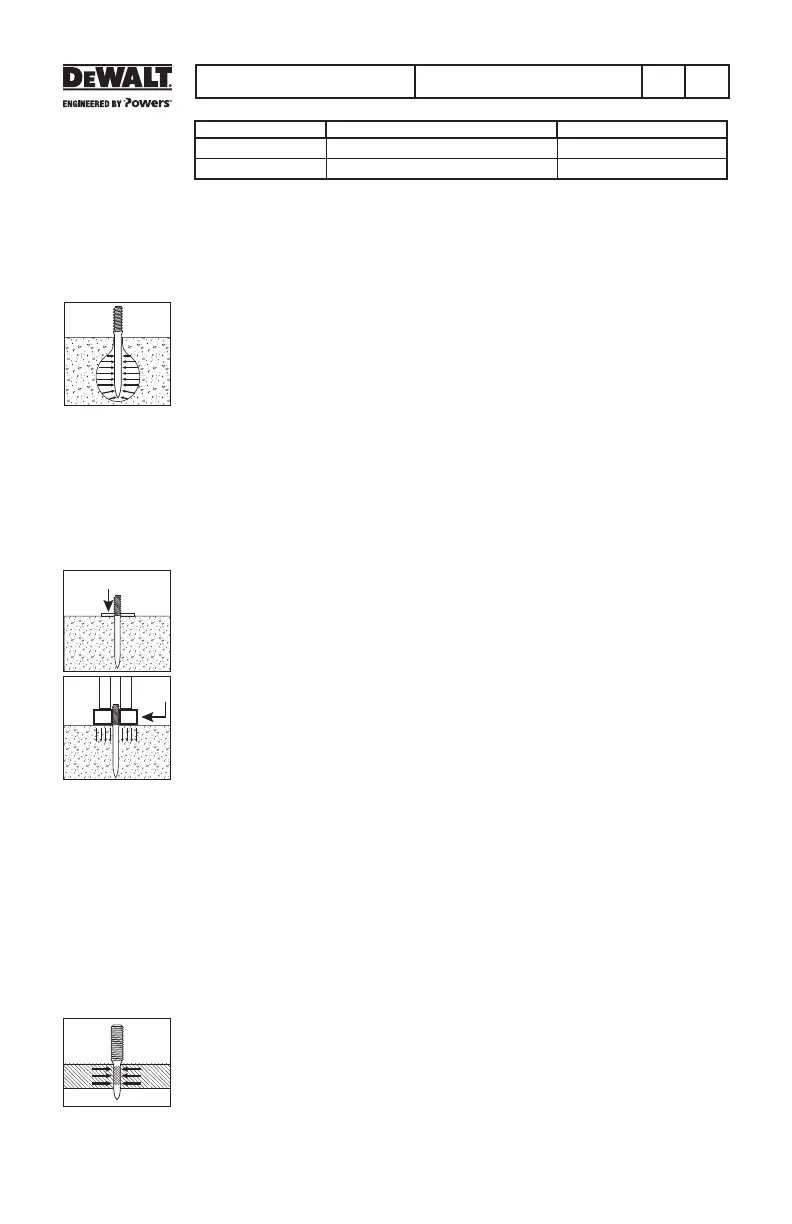

1. Another method used is to drive the fastener through a steel washer to improve the

appearance of the application.

2. A stop spall adapter mounted on the powder actuated tool can help to reduce

surface spalling.

FUNCTIONING IN STEEL

The load performance of a powder actuated fastener when installed into steel base

materials is based on the following factors:

1. Thickness of the steel

2. Tensile strength of the steel

3. Shank diameter of the fastener

4. Depth of point penetration through the steel

5. Fastener spacing and edge distance.

Loading...

Loading...