Do you have a question about the Dhollandia DH-RMM 25 and is the answer not in the manual?

| Brand | Dhollandia |

|---|---|

| Model | DH-RMM 25 |

| Category | Farm Equipment |

| Language | English |

Explains common safety signs like Danger, Warning, Caution, and Notice used in the manual.

Outlines manufacturer's liability limitations regarding liftgate modification, misuse, and installation.

Defines specific terminology related to the DH-RPL liftgate model.

Defines key installation parameters like lift arm length, vehicle floor height, and chassis total height.

Provides initial steps and considerations before commencing liftgate installation.

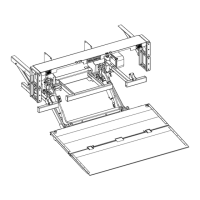

Details standard configurations and critical fitting dimensions for DHOLLANDIA RMM* liftgates.

Provides specific installation dimensions for the RMM* 51" platform depth model.

Provides specific installation dimensions for the RMM* 60" platform depth model.

Provides specific installation dimensions for the RMM* 63" platform depth model.

Directs users to contact distributors for queries on installation parameters.

Illustrates chassis cut dimensions for the RMM* 51" platform depth model based on bed heights.

Illustrates chassis cut dimensions for the RMM* 60" platform depth model based on bed heights.

Illustrates chassis cut dimensions for the RMM* 63" platform depth model based on bed heights.

Provides illustrations for rear sill cut requirements for different RMM* platform depth models.

Details the process for bolting or welding the bed extension to the vehicle's rear sill.

Guides on safely removing the liftgate from its skid and positioning it for installation.

Explains fitting and aligning mount plates to the lift frame and vehicle chassis.

Addresses chassis connection strength and anti-corrosion protection for metalwork.

Details mounting and routing for the main control toggle switch on the liftgate.

Guides on installing the cabin-mounted switch for remote liftgate operation.

Instructions for mounting and wiring the 2-button remote control unit.

Covers routing and connecting (+) battery and (-) ground cables to the electric motor.

Details steps for initial operation, checks, and hydraulic bleeding for service.

Explains how to adjust platform pitch and ensure levelness for safe operation.

Instructions for attaching side steps to the liftgate bed extension.

Covers the installation of optional 102" widening blocks for the bed extension.

Details the mounting of the optional bumper light cluster kit (OAM060).

Instructions for installing the optional walk ramp kit hanger bracket (OAM054).

Guides on lubricating articulation points with acid-free grease per the maintenance checklist.

Covers finishing steps, function execution, and Pre-Delivery Inspection (PDI) checklist completion.

Instructions for affixing various safety and information decals to the liftgate and vehicle.

Details the proper use and placement of the 'out of service' warning sign.

Provides a comprehensive overview of safety, mandatory, and prohibition signs used in the manual.

Lists required torque values for bolts and nuts to ensure secure connections.

Specifies minimum requirements for batteries, cables, and hydraulic oils for liftgate systems.

Advises on safe operator placement and risk reduction measures on the liftgate platform.

Concludes the manual with thanks and links to further information and support.

Indicates where to find wiring diagrams for the liftgate system.

Points to detailed procedures for preventative maintenance and care of liftgates.

Loading...

Loading...