17

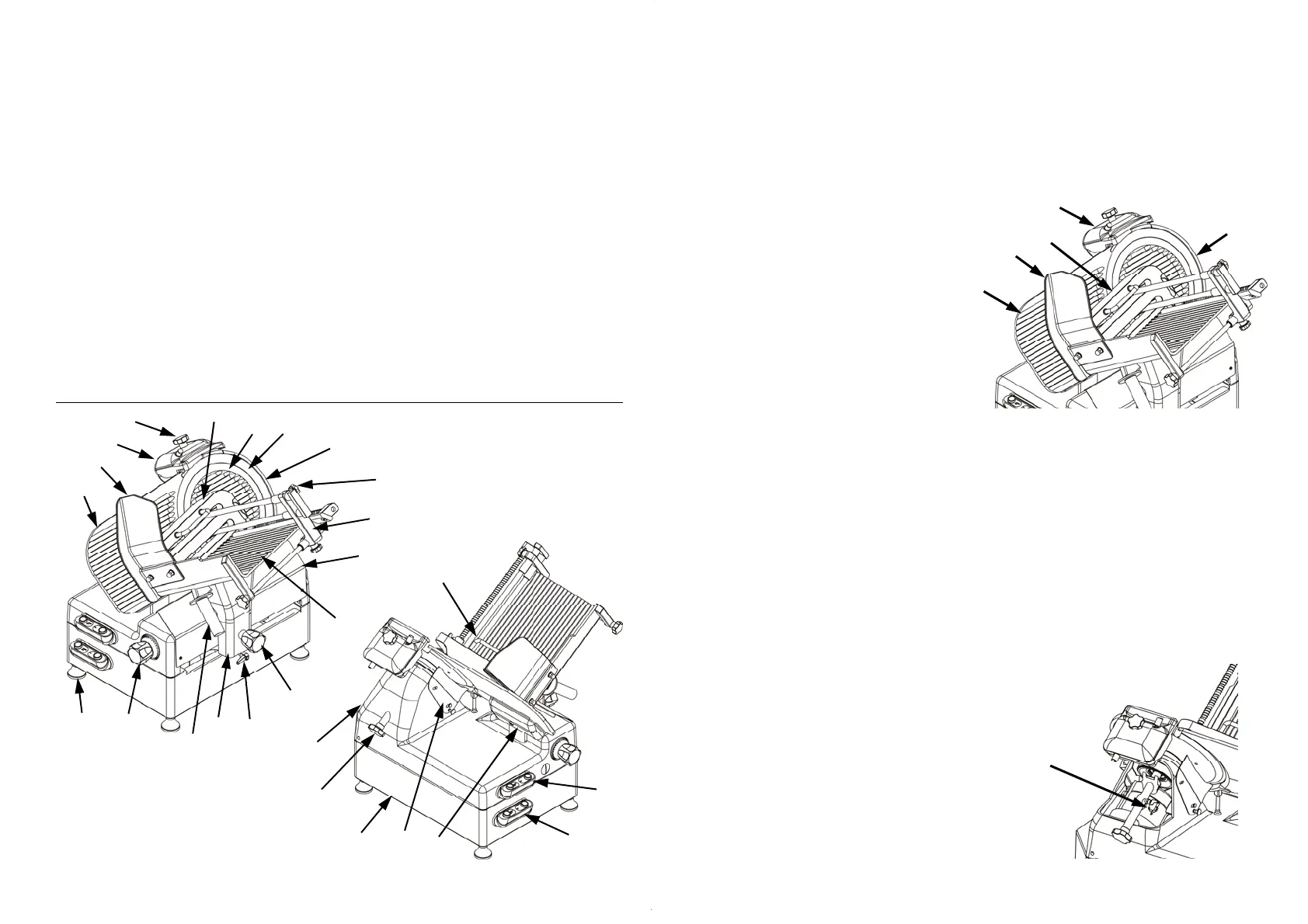

4.2 - SAFETY DEVICES INSTALLED ON THE MACHINE

4.2.1 - Mechanical safety

As far as mechanical safety is concerned, the slicer described in this manual

responds to:

- CEE 2006/42 machine directives.

4.2.2 - Electrical safety

Concerning electrical safety, the slicer described in this manual responds to:

- EEC 2006/95 low tension directive;

- Directive 2004/108 electromagnetic compatibility.

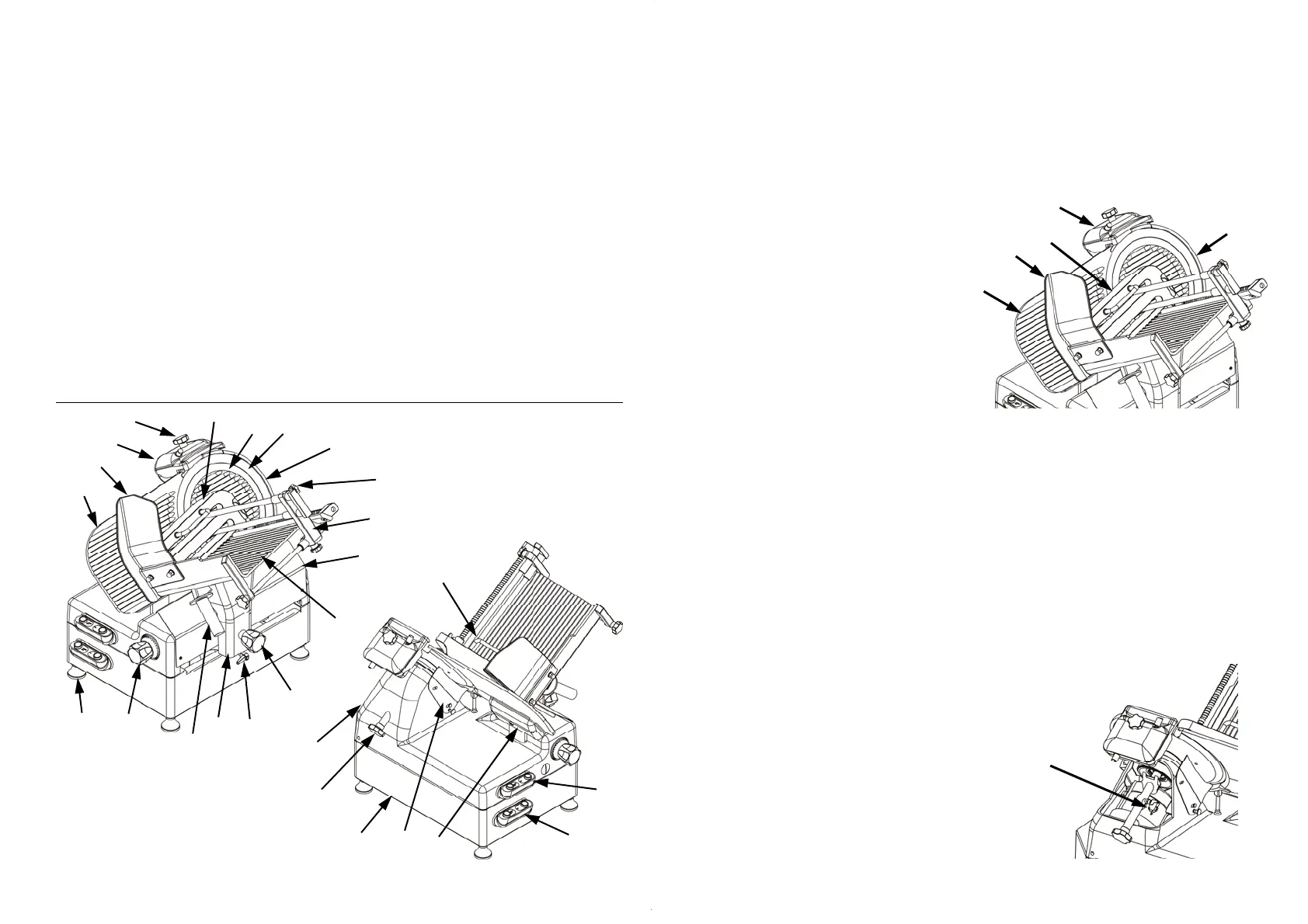

Fig. n°34

Micro

The slicer is fitted with:

- a microswitch on the bladeguard

causes the machine to stop if the bla-

deguard tie-rod is removed, and pre-

vents the slicer from being turned on

if the bladeguard is not properly

closed (Fig. n°35);

Safety is ensured by:

(Fig. n°34)

- Gauge plane (ref. n°1);

- Ring (ref. n°2);

- Cap (ref. n°3);

- Product pusher (ref. n°4);

- Handguard (ref. n°5);

- Trolley transported only when thick-

ness gauge plane is at “0”, at the end

of the run and towards operator side.

5

4

3

2

1

Fig. n°35

16

LEGEND:

1 Cap knob

2

3

4

5

6

7

8

9

10

11

12

13

Sharpener cover

Handguard

Thickness gauge hopper

Foot

Graduated hand grip

Stem grip

Stem

Mechanism lever

Stem knob

Product hopper

Edge

Adjustable product holder

14 Knob for adjustable product holder

15 Blade protection ring

16 Blade

17 Blade guard

18 Product pusher

19 Product pusher grip

20 Base

21 Blade guard tie rod hand grip

22 Shell

23 Deflector

24 Thickness gauge plate

25

Automatism control

26 Blade control

Fig. n°33

20

6

7

8

9

10

11

15

5

4

3

18

16

1

2

17

14

13

21

26

23

22

19

25

24

12

Loading...

Loading...