6

PC=corrected final pressure, psig

PR=final pressure as read, psig

T1=beginning temperature, degrees F

T2=final temperature, degrees F

Note: A rule of thumb is that the final pressure should not be less than half the

initial pressure after twenty-four hours.

6. If the system looses pressure at an unacceptably high rate, re-pressurize.

7. Leave the gas/air supply on and find the leak(s) using a “leak detector” or

bubble soap.

Should it be necessary to identify a leak, use non-ammonia based leak detection

soap, such as Snoop, by Swagelok. If unavailable use a simple mixture of dish

detergent and water. Ammonia and ammonia-based chemicals are extremely

incompatible with brass and brass is one of the main components in

transmission line and antenna systems. Ammonia makes the brass more

susceptible to stress-corrosion cracking.

8. Correct any leaks that are found.

9. Repeat steps 2 thru 5.

D. Purging System

The transmission line and the antenna system should be purged prior to applying

power.

1. Purge by pressurizing the antenna array to about 10 psi (70 kPa) with

compressed dehydrated air or cylinder nitrogen

2. Loosen the connection between the transmission line and input section to power

divider just enough to allow an air leak.

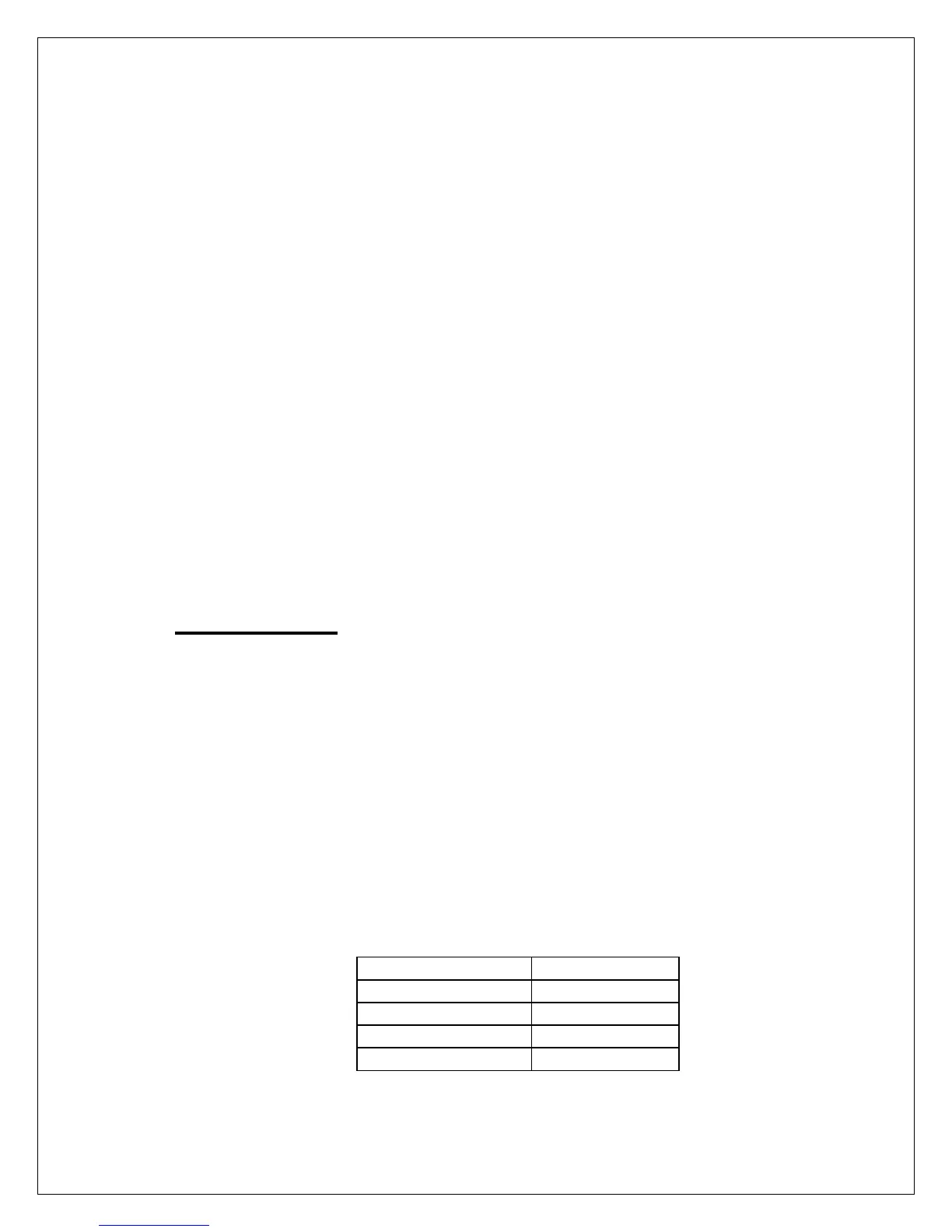

3. Purge using table below.

Note: Usually allow three volume changes of dry gas/air for a system. See

table below for approximate volumes inside various coax sizes.

VOLUME OF COAX PER

1000 FEET OF LENGTH

Diameter Volume

1-5/8” 13 cu. ft.

3-1/8” 50 cu. ft.

4-1/16” 90 cu. ft.

6-1/8” 200 cu. ft.

One full nitrogen cylinder, size K, contains about 240 cubic feet of gas.

Loading...

Loading...