DigitAx User Guide

Issue code: dgxu4

11-4

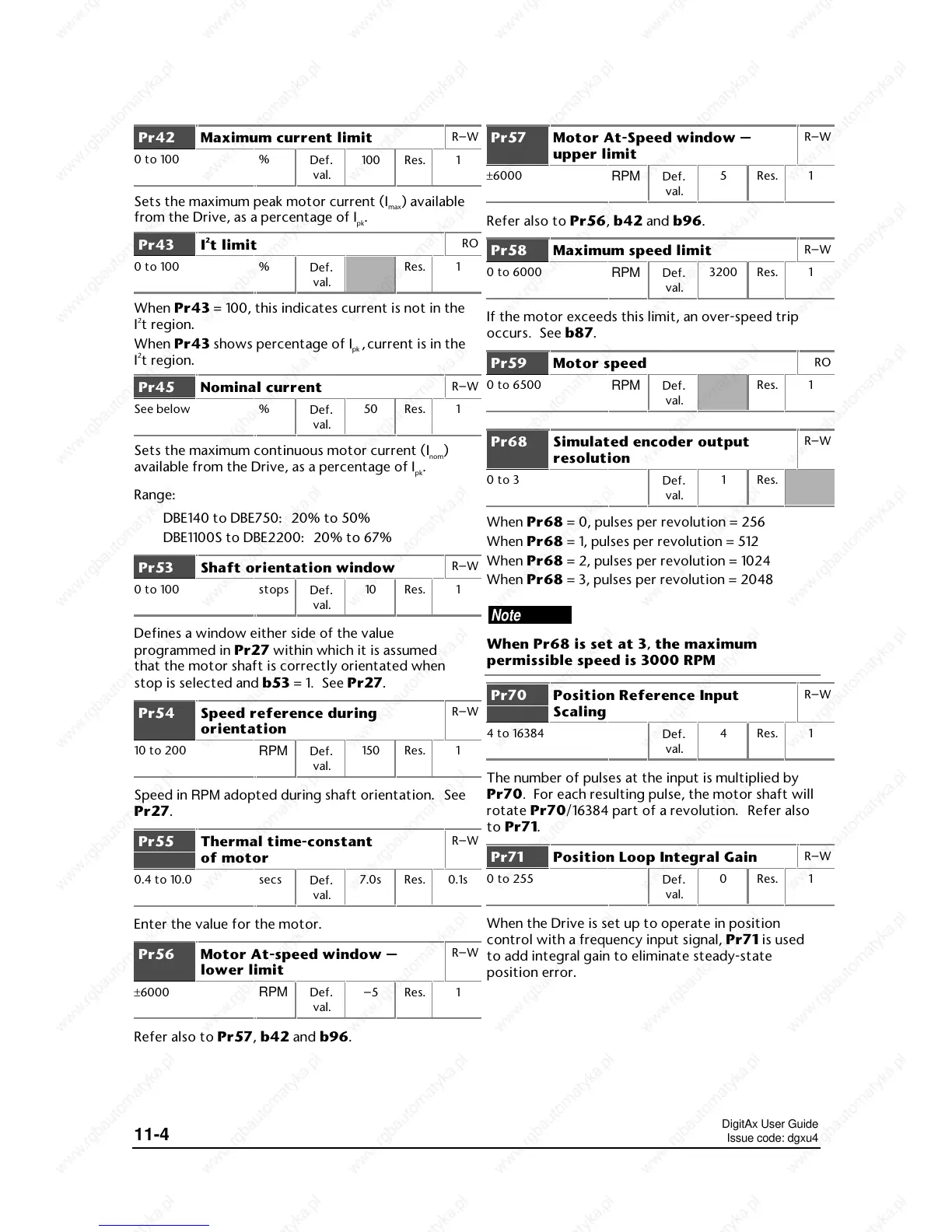

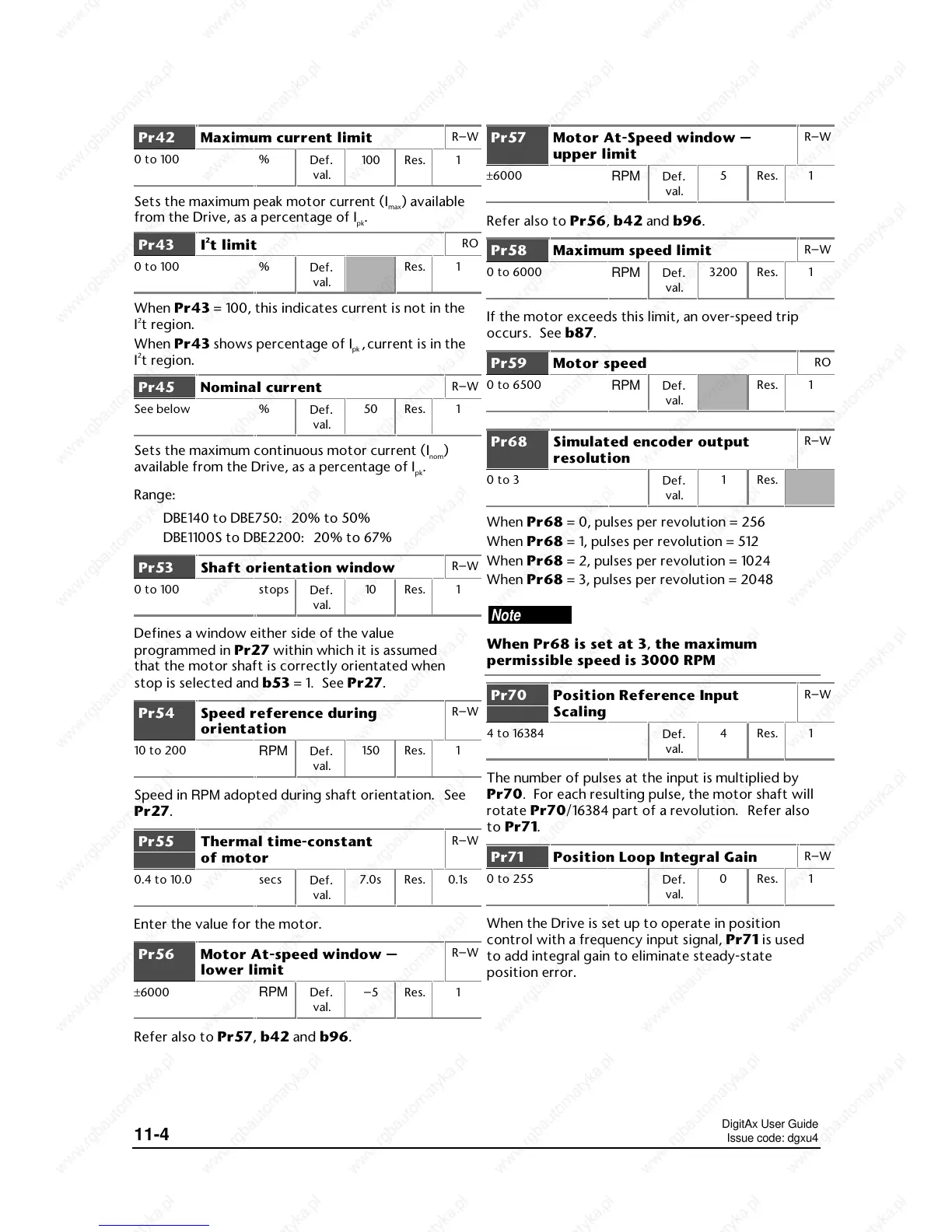

Pr42 Maximum current limit

R–W

0 to 100 %

Def

.

val.

100 Res. 1

Sets the maximum peak motor current (I

max

) available

from the Drive, as a percentage of I

pk

.

Pr43 I

2

t limit

RO

0 to 100 %

Def

.

val.

Res. 1

When Pr43 = 100, this indicates current is not in the

I

2

t region.

When Pr43 shows percentage of I

pk

,

current is in the

I

2

t region.

Pr45 Nominal current

R–W

See below %

Def

.

val.

50 Res. 1

Sets the maximum continuous motor current (I

nom

)

available from the Drive, as a percentage of I

pk

.

Range:

DBE140 to DBE750: 20% to 50%

DBE1100S to DBE2200: 20% to 67%

Pr53 Shaft orientation window

R–W

0 to 100 stops

Def

.

val.

10 Res. 1

Defines a window either side of the value

programmed in Pr27 within which it is assumed

that the motor shaft is correctly orientated when

stop is selected and b53 = 1. See Pr27.

Pr54 Speed reference during

orientation

R–W

10 to 200

RPM Def.

val.

150 Res. 1

Speed in RPM adopted during shaft orientation. See

Pr27.

Pr55 Thermal time-constant

of motor

R–W

0.4 to 10.0 secs

Def

.

val.

7.0s Res. 0.1s

Enter the value for the motor.

Pr56 Motor At-speed window —

lower limit

R–W

±6000

RPM Def.

val.

–5 Res. 1

Refer also to Pr57, b42 and b96.

Pr57 Motor At-Speed window —

upper limit

R–W

±6000

RPM Def.

val.

5 Res. 1

Refer also to Pr56, b42 and b96.

Pr58 Maximum speed limit

R–W

0 to 6000

RPM Def.

val.

3200 Res. 1

If the motor exceeds this limit, an over-speed trip

occurs. See b87.

Pr59 Motor speed

RO

0 to 6500

RPM Def.

val.

Res. 1

Pr68 Simulated encoder output

resolution

R–W

0 to 3

Def

.

val.

1 Res.

When Pr68 = 0, pulses per revolution = 256

When Pr68 = 1, pulses per revolution = 512

When Pr68 = 2, pulses per revolution = 1024

When Pr68 = 3, pulses per revolution = 2048

Note

When Pr68 is set at 3, the maximum

permissible speed is 3000 RPM

Pr70 Position Reference Input

Scaling

R–W

4 to 16384

Def

.

val.

4 Res. 1

The number of pulses at the input is multiplied by

Pr70. For each resulting pulse, the motor shaft will

rotate Pr70/16384 part of a revolution. Refer also

to Pr71.

Pr71 Position Loop Integral Gain

R–W

0 to 255

Def

.

val.

0 Res. 1

When the Drive is set up to operate in position

control with a frequency input signal, Pr71 is used

to add integral gain to eliminate steady-state

position error.

Loading...

Loading...