ENGINE ADJUSTMENT

Every engine has been adjusted to average mixture sengs which will most likely allow the engine to

start and run in most locaons. However, as altudes and barometric pressures vary by locaon, it is very

likely that the carburetor mixture sengs will need to be adjusted to obtain opmum performance.

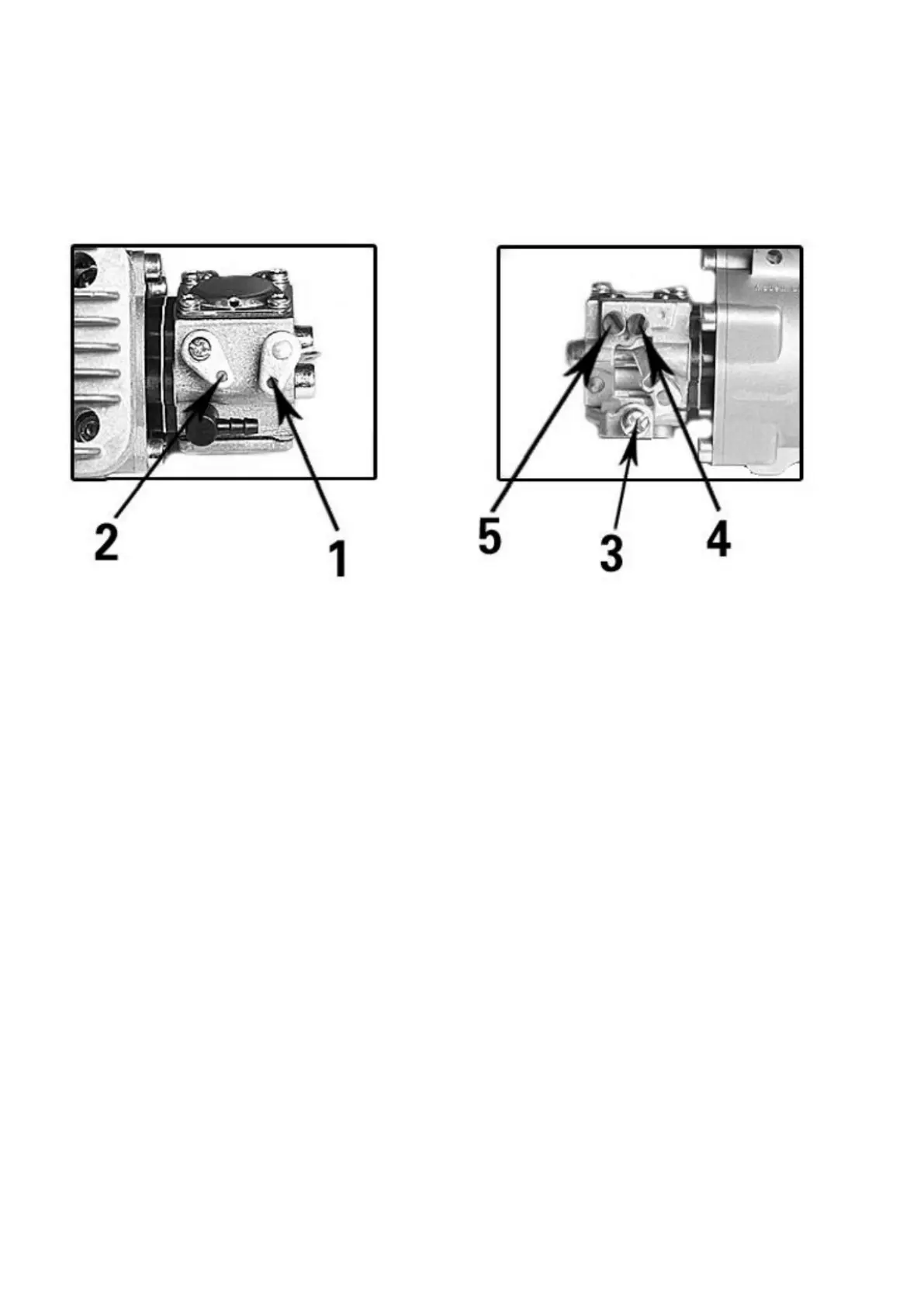

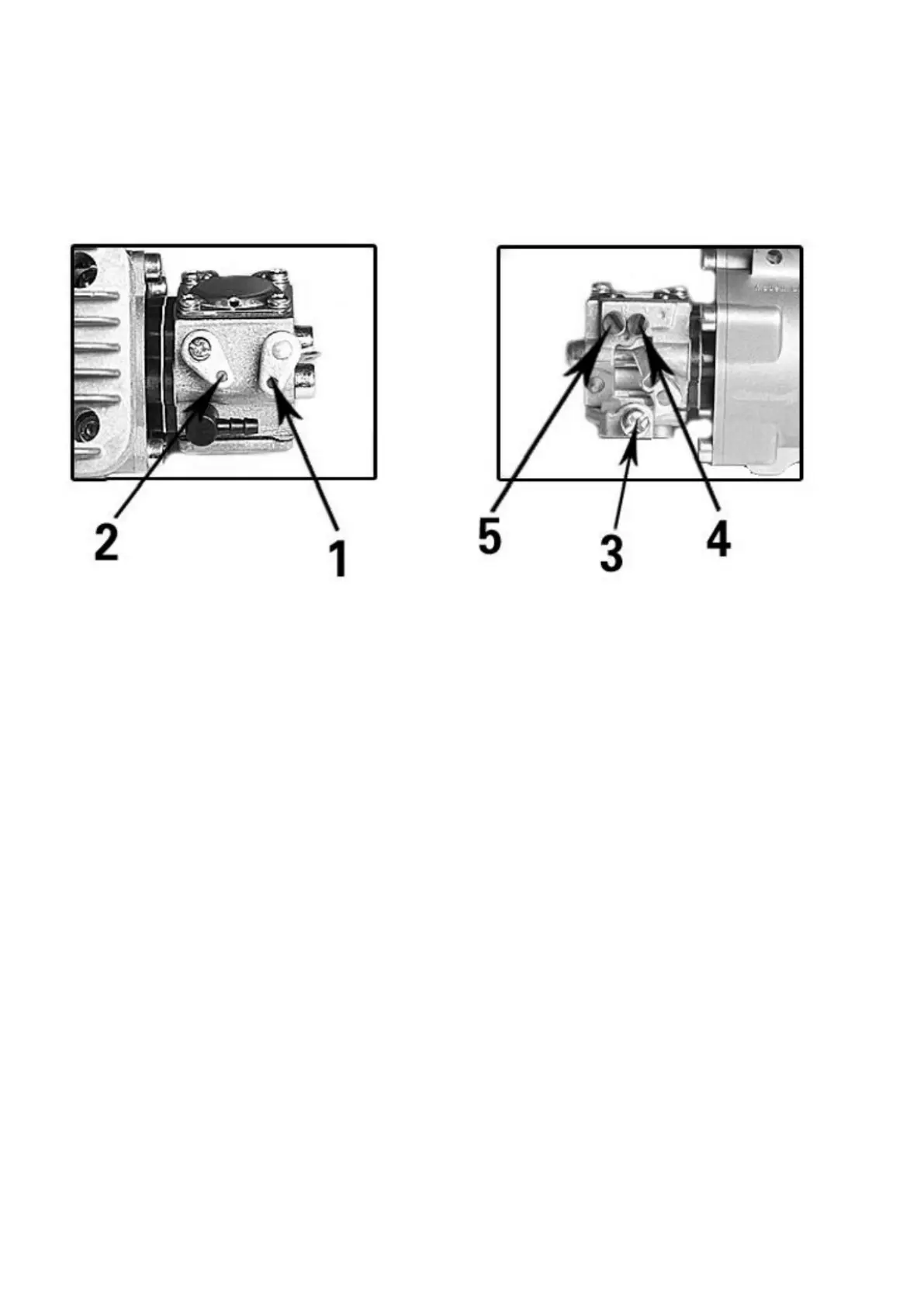

(1) Choke Lever (2) Throle Lever (3) Idle Speed Adjustment Screw

(4) Low Speed Mixture Adjustment Screw (5) High Speed Mixture Adjustment Screw

ADJUSTMENT: A general starng point is 1.25 turns out for the low speed needle (4), and 1.5 turns out

for the high speed needle (5).

Low Speed Adjustment Adjust the Low needle unl you achieve a smooth idle and a reliable transion to

high throle. If the engine dies when the throle is advanced, the mixture is likely too lean. If the engine

stumbles when the throle is advanced, the mixture is likely too rich.

High Speed Adjustment The High Speed needle adjusts the mid and high RPM mixture seng. Best prac-

ce is to set the high speed needle to achieve maximum RPM and then open an 1/8 of a turn to allow for

altude. If ever the engine slows or stops while at full throle, the high speed mixture is most likely too

lean. In this situaon open the High Speed Screw 1/8 to 1/4 of a turn.

Cauon: Don't be tempted to run an overly rich mixture. A too rich mixture will only result in poor en-

gine performance (engine stopping or spluering when accelerang or deaccelerang), pre-mature car-

bon buildup, a fouled plug and excessive exhaust residue. However, a lean mixture will also damage

the cylinder and piston. A lean run engine is not covered under warranty.

During break in and aer few runs at full throle we suggest you unscrew and check the spark plug, it

appears to be a slight yellow colour if mixture had been set properly.

Loading...

Loading...