5 MN1661

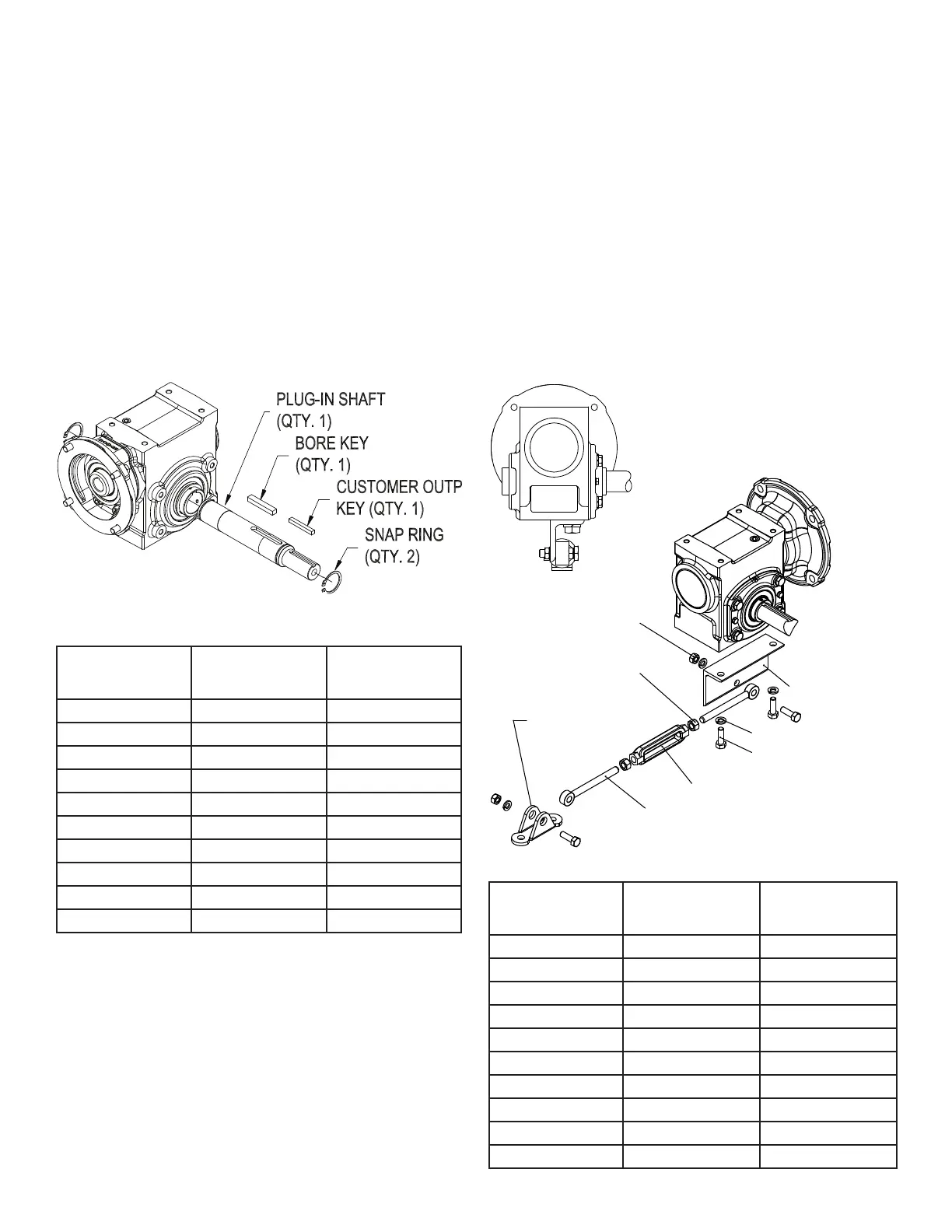

PLUG-IN SHAFT KIT

Install a snap ring on the plug-in shaft near the shaft extension

end. Insert the bore key into the key seat in the plug-in shaft.

Remove the two keyway set screws and loosen the remaining

four set screws in the hollow bore shaft in the reducer. (The

keyway set screws may be used but are not required.) Holding

the plug-in output shaft extension, slide the plug-in shaft into

the hollow bore. Install the second snap ring into the groove in

the plug-in shaft on the non-drive end. Hand tighten one of the

four set screws and then hand tighten a set screw in the same

position on the opposite side of the reducer. Continue to alternate

tightening the set screws until all four set screws have been hand

tightened. After all the set screws have been hand tightened,

use a torque wrench to tighten the set screws to the values in the

table below.

NOTE: Apply a thread-locking compound to the raised diameters

on the plug-in shaft before inserting into the reducer for improved

performance.

Reducer

Size

Bolt or Screw Size

Tightening

Torque

(ft-lb)

13 1/4-28 8

15 1/4-28 8

17 1/4-28 8

20 1/4-28 8

23 1/4-28 8

26 1/4-28 8

30 5/16-24 15

35 5/16-24 15

40 3/8-24 28

47 3/8-24 28

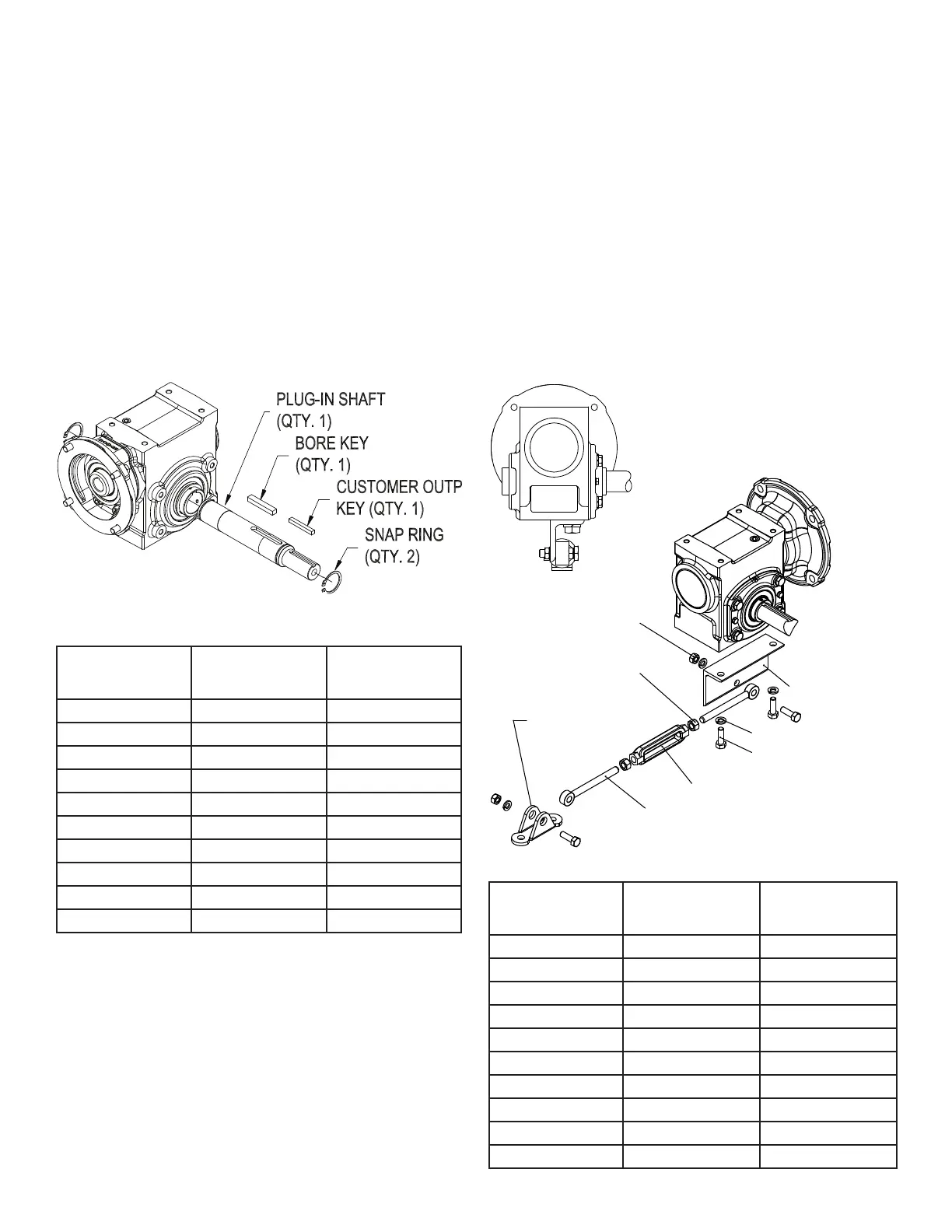

TIE ROD KIT

Assemble tie rod assembly components—right-hand threaded

rod end, right-hand nut, turn buckle, left-hand threaded rod end

and left-hand nut. The tie rod mounting bracket can be located

on the top or bottom of the reducer. Using the diagram below

as a reference, position the bracket so the tie rod assembly

is on the side of the reducer closet the driven equipment.

Install the mounting bracket cap screws and lock washers and

rod assembly onto the mounting bracket and the fulcrum onto

the tie rod assembly using the supplied hardware (cap screws,

lock washers and nuts). Hardware should only be hand-tight.

Install the fulcrum at an angle not more than 30 degrees from the

motor centerline using customer supplied hardware. The tie rod

assembly length can be adjusted by rotating the tie rod assembly

turn buckle. Tighten the tie rod assembly mounting hardware.

Tighten tie rod assembly jam nuts against the turn buckle to lock

the assembly’s length.

Reducer

Size

Bolt or Screw Size

Tightening

Torque

(ft-lb)

13 1/4-20 8

15 1/4-20 8

17 5/16-18 17

20 3/8-16 30

23 3/8-16 30

26 3/8-16 30

30 7/16-14 48

35 7/16-14 48

40 5/8-11 130

47 5/8-11 130

MOUNTING BRACKET (QTY. 1)

THREADED ROD END (QTY. 2)

TURNBUCKLE (QTY. 1)

FULCRUM (QTY. 1)

JAM NUT (QTY. 2)

HEX HEAD CAP SCREW (QTY. 4)

LOCKWASHER (QTY 4)

NUT (QTY. 2)

Loading...

Loading...