6 MN1661

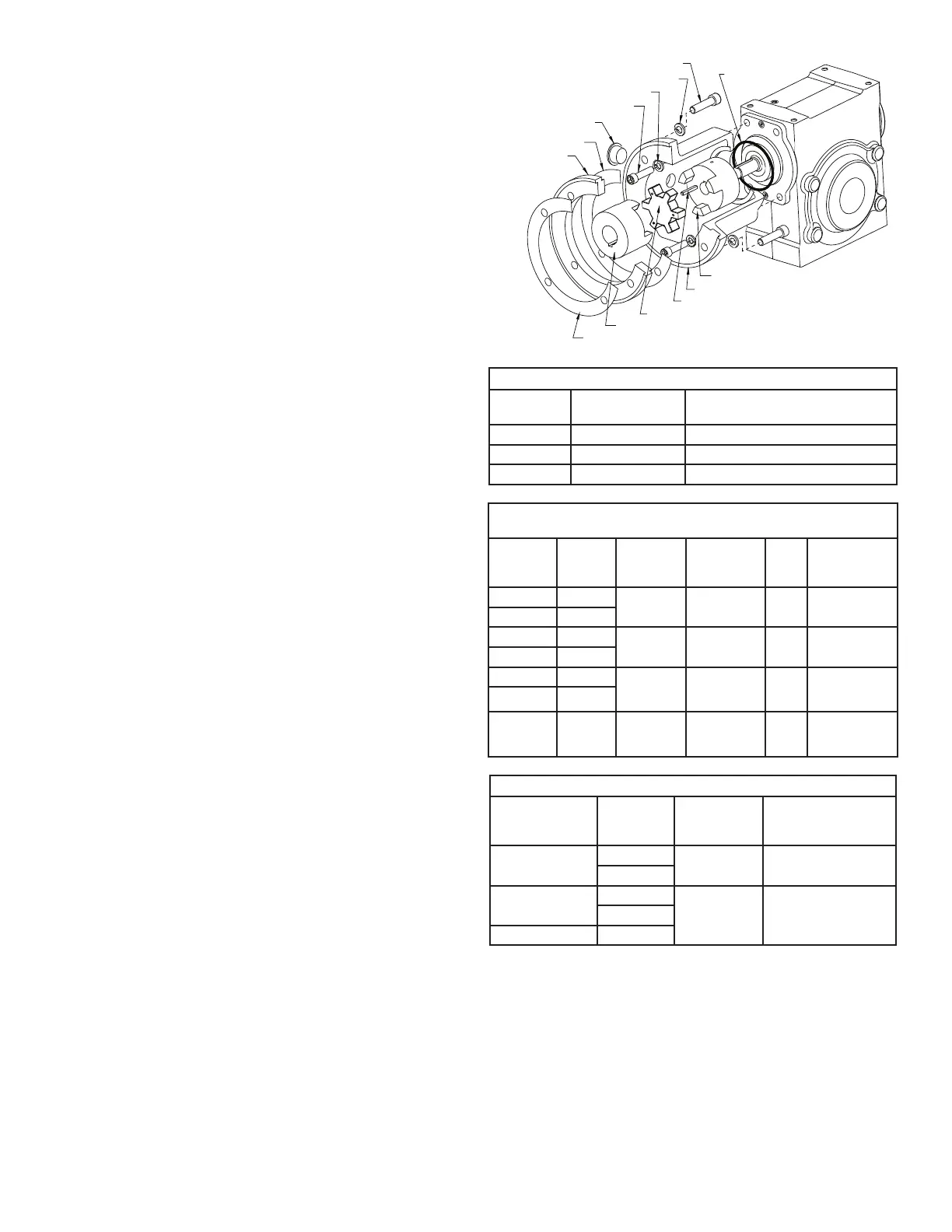

MOTOR ADAPTER KIT

Locate the reducer on a secure surface with the input shaft facing

up. Loosen the set screws in both coupling halves. Position the

input shaft. Insert the reducer key and tighten the set screw(s).

Coupling hubs may contain one or two set screws. Rotate the

coupling hub one complete revolution to verify the number of set

screws. Torque all set screws per Table 2 below. A hex socket

and extension, not a T-handle wrench, must be used to tighten

the set screws. Install the o-ring on the motor adapter and install

the motor adapter on the reducer using the motor adapter bolts

and copper washers. Tighten the motor adapter bolts to the

torque values listed in Table 1 below. Install the gasket between

gasket, place and align the gasket onto the motor face for the 56

and 140TC frame motors and onto the motor adapter face for the

180, 210, and 250TC frame motors. A small amount of grease

or other suitable product can be placed on the gasket in three

locations to temporarily hold gasket into place.

NOTE: On 210 and 250 frame motor adapter kits, an adapter plate

and additional gasket may be supplied. Place the adapter plate

onto the gasket on the motor adapter and then place the additional

gasket onto the adapter plate.

Insert the elastomeric element into the reducer coupling half.

Place the motor coupling half onto the elastomeric element.

Install the motor key into the motor shaft. Stake the key into

the motor shaft keyway using a punch or small chisel. Align the

motor shaft key with the coupling half keyway and slowly lower

or the adapter plate face. No visible gap should be present.

Do not use the motor mounting bolts to pull the motor onto

the motor adapter. Install the motor mounting bolts and lock

washers. Torque the motor mounting bolts per Table 3 below.

Looking through the access hole, verify that the coupling faces

are in full contact with the coupling elastomeric element. To

set the required gap, insert a .010–.030” shim or feeler gauge

between the elastomeric element and the motor coupling half.

failure. Tighten the motor coupling set screw(s). Coupling hubs

may contain one or two set screws. Rotate the coupling hub one

complete revolution to verify the number of set screws. Torque all

set screws per Table 2 below. Install access hole plug.

NOTE: The Tigear-2 three piece couplings are sourced from

two manufacturers. Tigear-2 reducers may contain either

manufacturer’s coupling.

O-RING (QTY.1)

MOTOR ATTACHMENT BOLTS (QTY.4)

LOCKWASHER (QTY.4)

ACCESS PLUG (QTY.1)

GASKET (QTY.1)

ADAPTER PLATE

(QTY.1 - SEE TEXT)

GASKET (QTY.1 -SEE TEXT)

MOTOR COUPLING HALF (QTY.1)

ELASTOMERIC ELEMENT (QTY.1)

MOTOR ADAPTER BOLT (QTY.4)

REDUCER COUPLING HALF (QTY.1)

LOCKWASHER (QTY.4)

MOTOR ADAPTER (QTY.1)

REDUCER KEY (QTY.1)

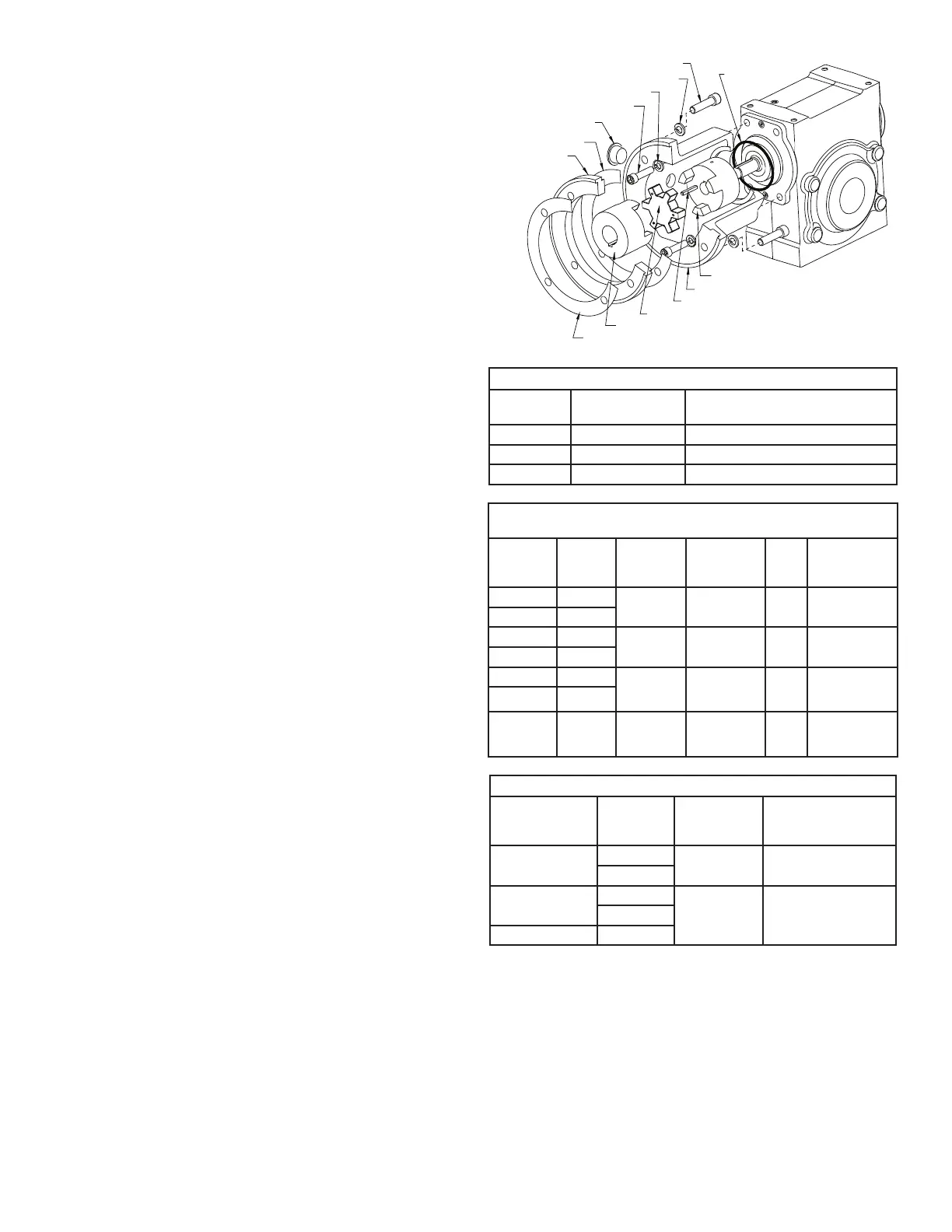

Motor Adapter Kit Table 1–Motor Adapter Bolt Torque

Reducer

Size

Bolt or

Capscrew Size

Tightening Torque

(non-lubricated)

13 - 20 5/16 - 18 17 ft-lb

23 - 30 3/8 - 16 30 ft-lb

35 - 47 7/16 - 14 48 ft-lb

Motor Adpater Kit Table 2–Three Piece Coupling Motor &

Reducer Coupling Set Screw Torque

Reducer

Size

C-Face

Coupling

Size

Set Screw

Size

Hex

Key

Size

Tightening

Torque

13A - 30A 56C

L075 1/4-20 x 5/16 1/8

78 - 87 in-lb

(6.5 - 7.3 ft-lb)

13A - 15A 140TC

35A 56C

L090 1/4-20 x 5/16 1/8

78 - 87 in-lb

(6.5 - 7.3 ft-lb)

17A - 35A 140TC

40A - 47A 140TC

L099 5/16-18 x 3/8 5/32

150 - 165 in-lb

(12.5 - 13.8

ft-lb)

23A - 47A 180TC

35A - 47A 210TC L110 3/8-16 x 1/2 3/16

260 - 290 in-lb

(21.7 - 24.2

ft-lb)

Table 3–Motor Mounting Bolt Torque

Reducer Size C-Face

Bolt or

Capscrew

Size

Tightening Torque

(non lubricated)

13 - 40 56C 3/8 -16 23 ft-lb

140TC

23 - 47 180TC 1/2 - 13 57 ft-lb

210TC

250TC

Loading...

Loading...