10. Cylinder block/head

156

Valve

General Information

The overhead valves are actuated via chilled cast iron

tapets, push rods and rocker arms from the camshaft.

Check of Valve

After cleaning the valves with clean diesel oil, measure the

valve as follow.

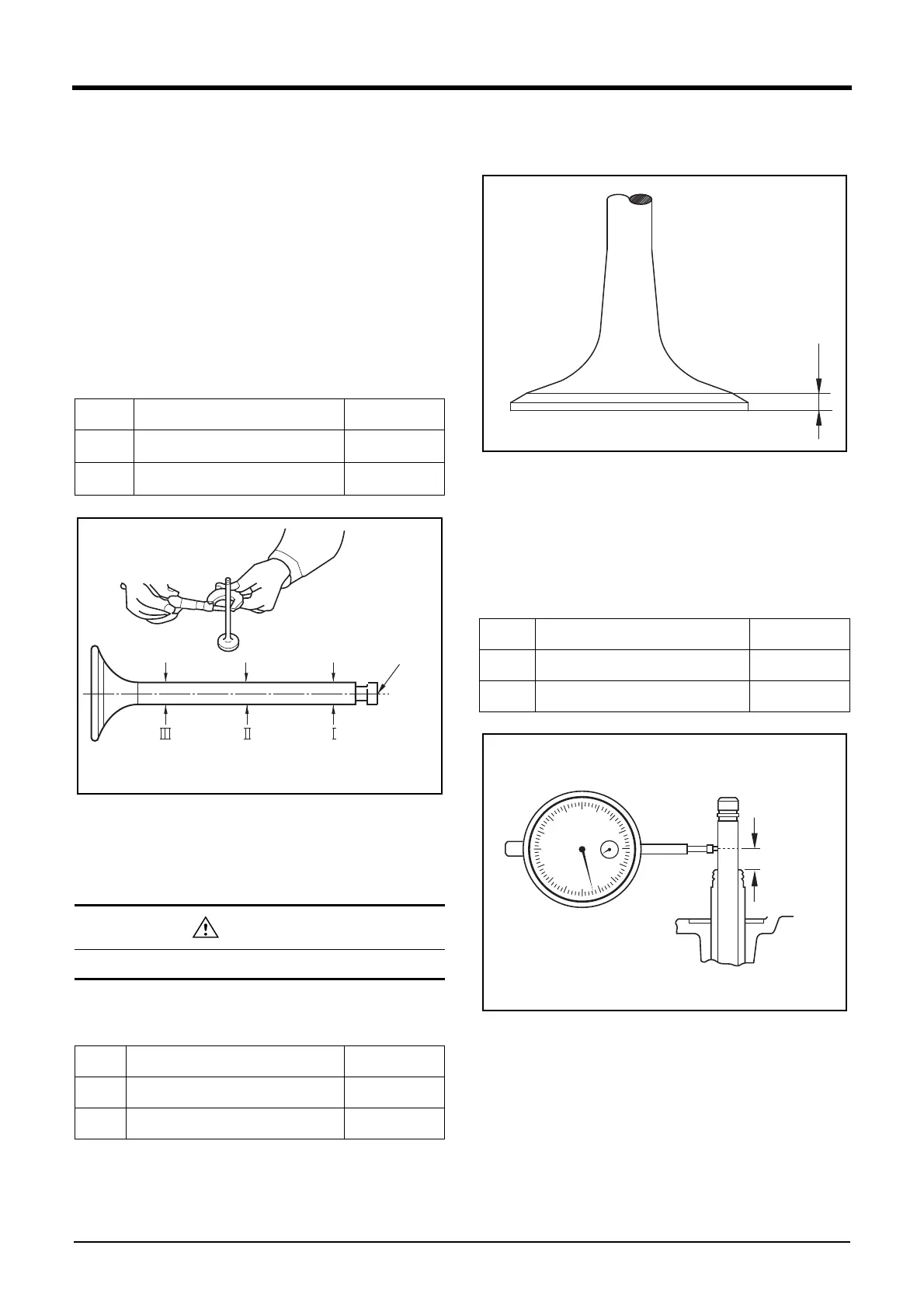

1. Measure the valve stem’s outside diameter at upper,

middle, and lower to determine the wears and when the

wear limit is more than limit, replace the valves.

DV2213117A_E

2. inspect the scratch and wear of valve stem seal

contacting face, and if necessary correct with the grinding

paper but if severe replace it.

3. if valve head thickness becomes less than limit, replace

the valve.

EE1OM066

Check of Valve Guide

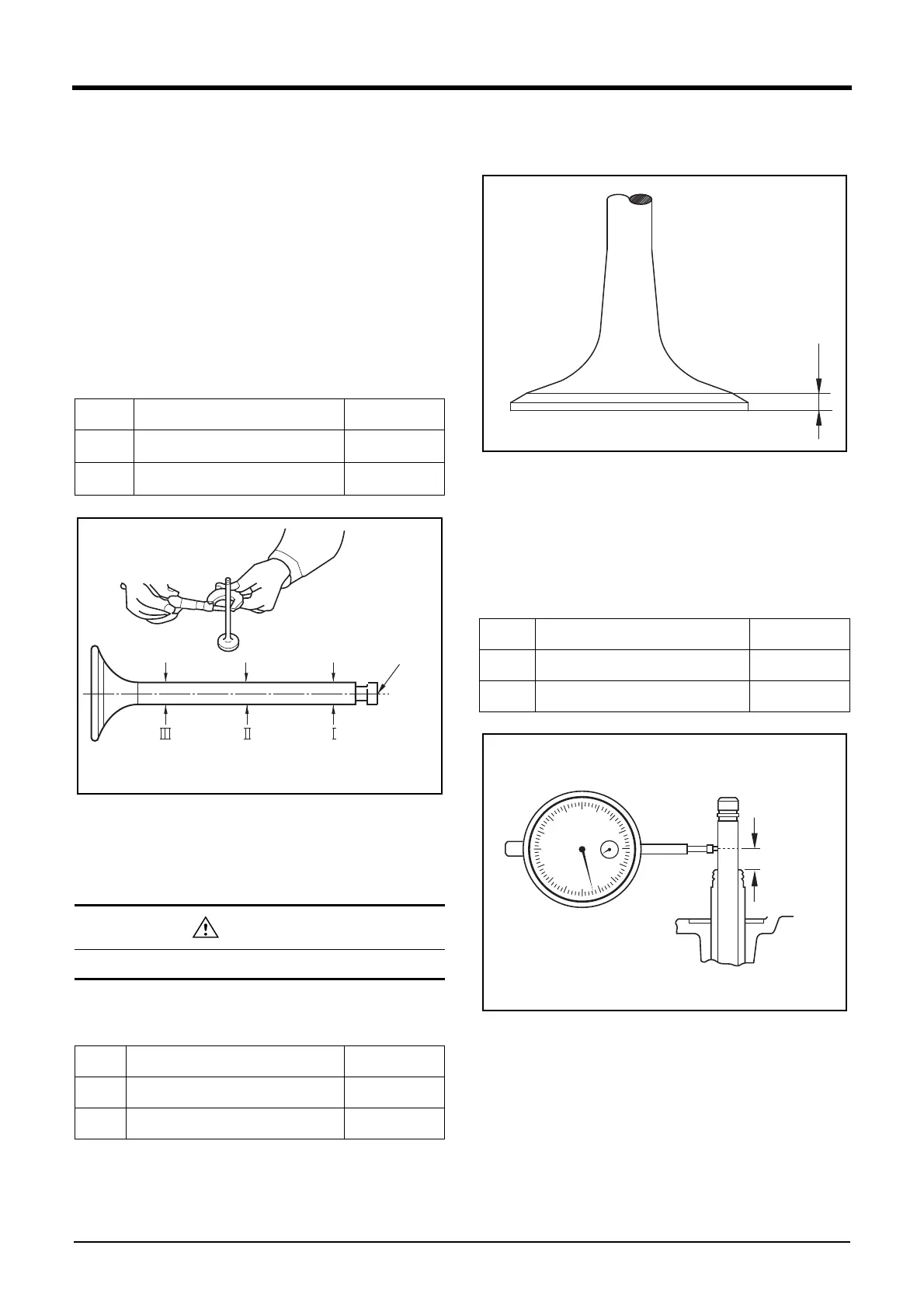

1. Inser the valve into valve guide and measure the clear-

ance between valve and valve guide by the shaking

degree of valve. If the clearance is bigger, measure the

valve and then replace the more worn valve guide.

DV2213119A_E

2. If the valve guide has already been replaced, measure

the center with valve seat if it deviates or not and if

abnormal it must be corrected.

Note) Simultaneously be processed when in guide reamer

process.

Valve Seat

1. Visual inspection: Inspect the damage and wear of valve

seat and if necessary replace.

Item Standard Limit

In.

Ø11.969 ~ Ø11.980mm Ø11.949mm

Ex.

Ø11.945 ~ Ø11.955mm Ø11.914mm

If the damage is severe, replace new one.

Item Standard Limit

In. 4.6 ~ 5.0mm 4.1mm

Ex. 4.33 ~ 4.83mm 3.83mm

Item Standard Limit

In. 0.020 ~ 0.049mm 0.10mm

Ex. 0.045 ~ 0.074mm 0.15mm

Loading...

Loading...