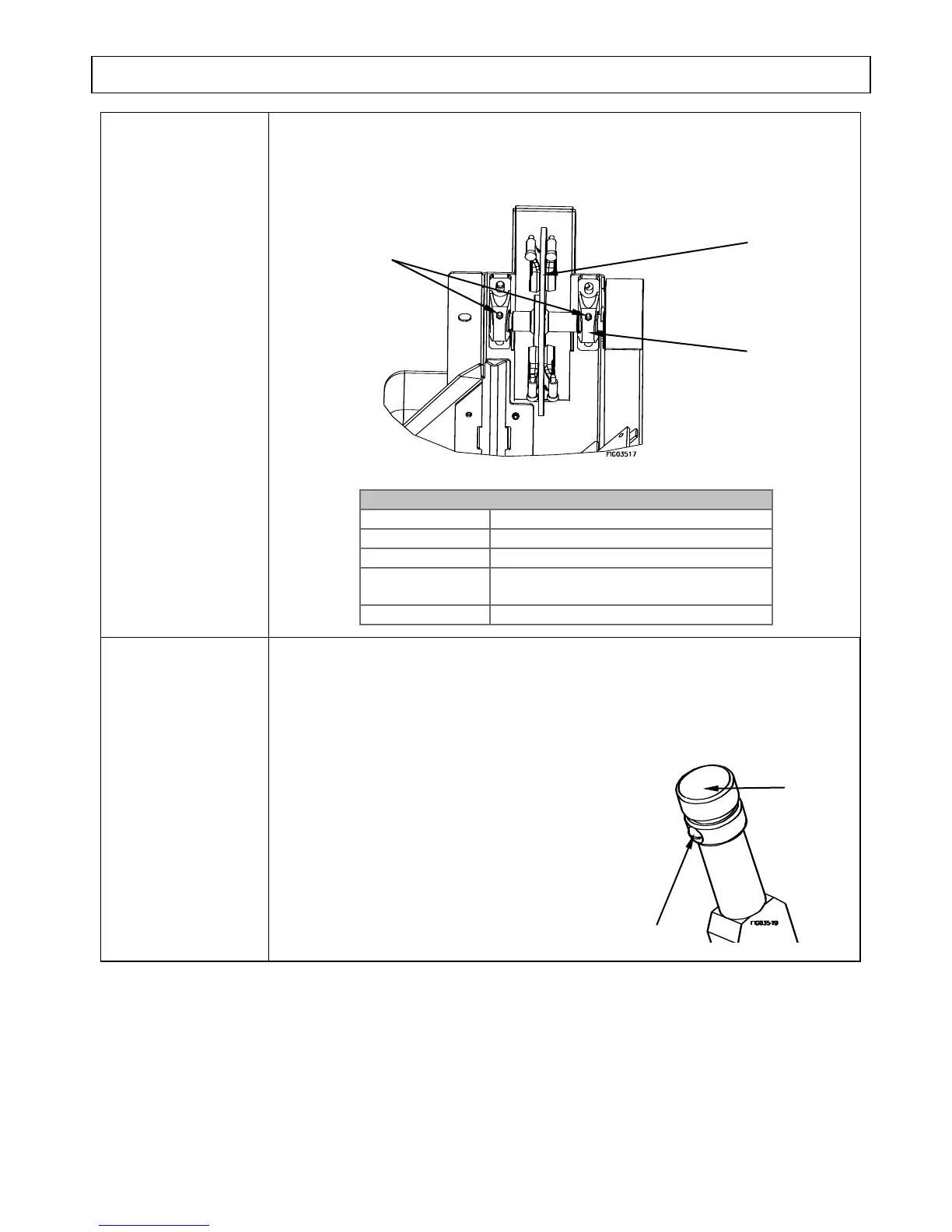

Cutter shaft bearings should be greased.

The cutter shaft bearing is greased by pumping grease into zerks located on

the housing of the bearing.

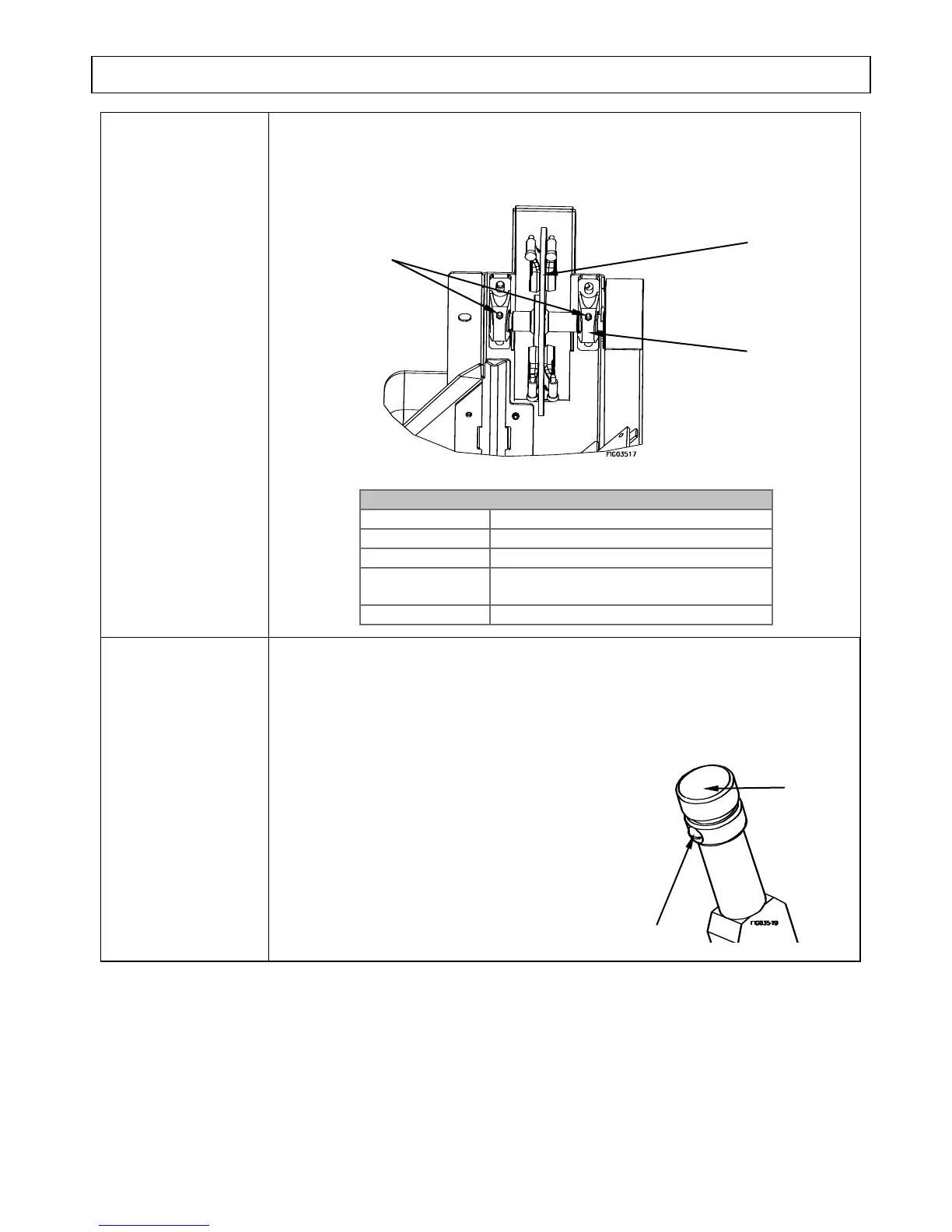

Check that the brake is functioning properly.

Lock the brake; push down on handle bar so that cutter wheel is off

the ground.

Push or pull the grinder- if the brake is loose, the wheel will rotate.

To adjust braking tension:

Unscrew setscrew.

Turn knob clockwise to increase

tension or counter-clockwise to

decrease tension.

Once you have set the brake to the

proper tension, tighten setscrew to

lock adjustment knob.

Loading...

Loading...