20 DR

®

POWER GRADER

Chapter 4: Maintaining The DR POWER GRADER

Regular maintenance is the way to ensure the best performance and long life of your machine. Please refer to this Chapter for

maintenance intervals and procedures.

Regular Maintenance Checklist

ROCEDURE BEFORE EACH USE EVERY 25 HOURS

Check general equipment condition e.g., Nuts, Bolts, welds, etc.

▲

Hose down the DR POWER GRADER

▲

Check condition of Shear Pin

▲

Lubricate Wheels as needed

Cleaning the Power Grader

1.

Use a Hose or Pressure Washer to clean the DR POWER GRADER to keep the Scarifying Teeth Plate, Wheels etc. clean and

clear of debris.

Checking the Shear Pin

1. Check the Shear Pin for signs of wear or damage. Replace the Shear Pin if worn or damaged.

Replacing the Tooth Bar

Tools Needed:

Two 9/16" Wrenches

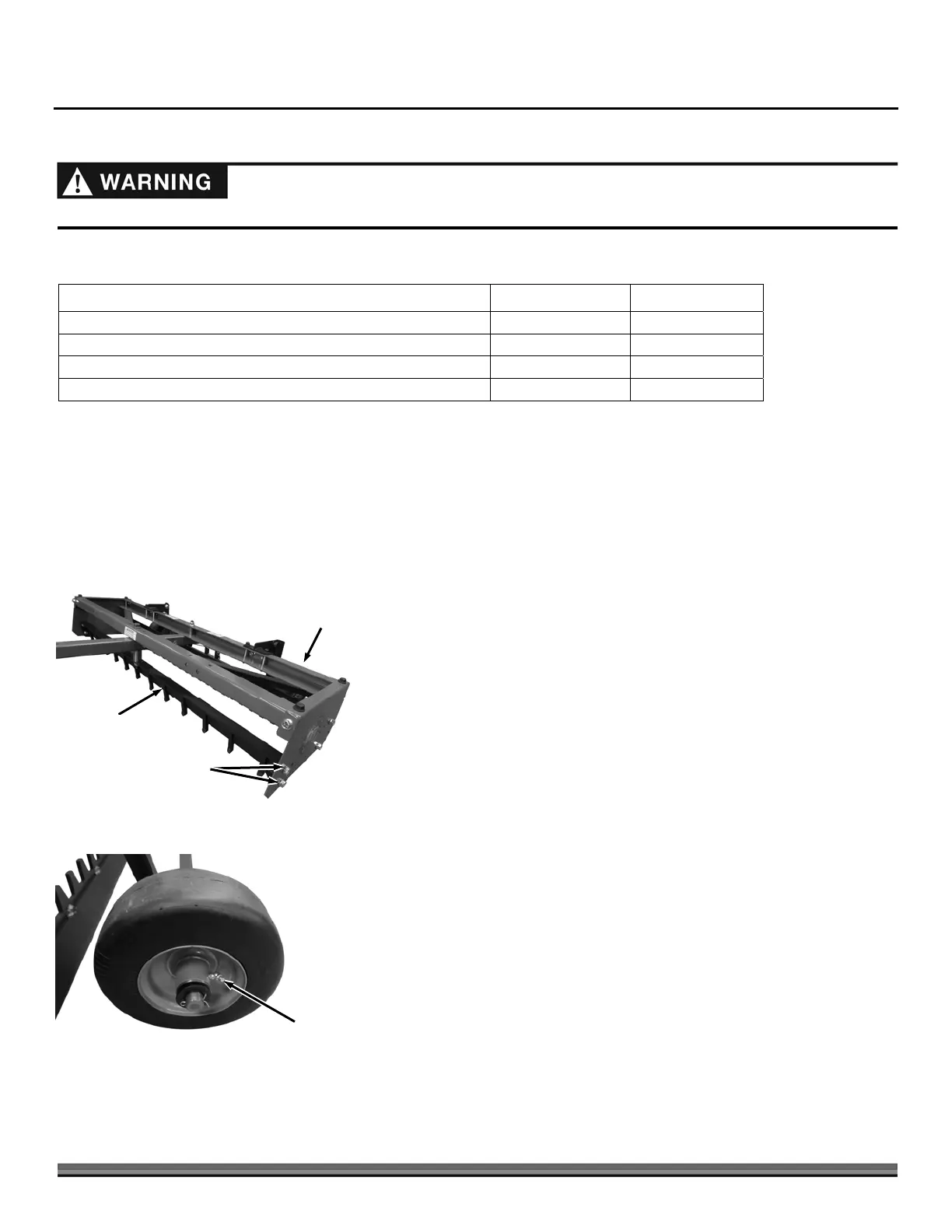

1. Use the Height Adjust to lower the Wheels to raise the front of the DR

POWER GRADER off the ground.

2. Remove the Bolts and Locknuts on both ends of the Tooth Bar using two

9/16" Wrenches (Figure 43).

3. Remove the old Tooth Bar and clean the mounting area of the Frame.

4. Position the new Tooth Bar and secure with the Bolts and Locknuts.

Lubrication

Tools and Supplies Needed:

Flexible hose grease gun

Lithium grease

Clean Rags

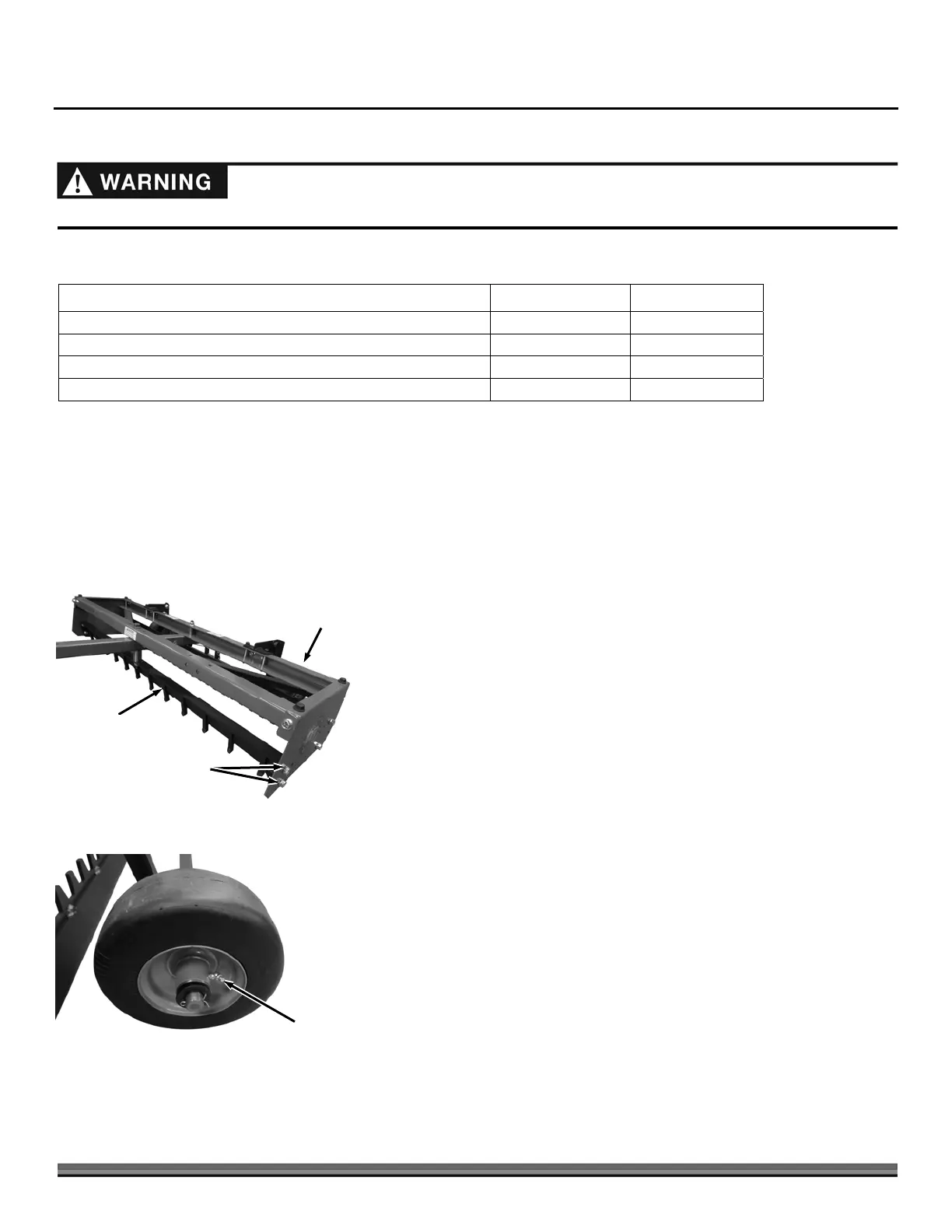

1. Clean the Grease Fitting with a clean Rag (Figure 44).

2. Lubricate the Wheels at the grease fitting every 25 hours of operation.

Note: Pump the grease gun only until you feel slight resistance (2 - 3 pumps).

Before performing any maintenance, you must first shut off the tow vehicle, remove the key and set the parking brake.

Tooth Bar

Figure 43

Bolts and

Locknuts

Wheels

Down

Grease

Fitting

Figure 44

Loading...

Loading...