Before each starting, check if the winch is not damaged.

Repair or replace any defective components.

Periodically check the winch mounting and make sure that

all screws are properly tightened.

The strength of the steel rope (cable) provided with the

winch is appropriate to the power and intended use of

each specic winch.

The diameter and length of the cable for the same winch

model may vary, maintaining constant strength and safety

parameters.

Before each use, check the condition of the cable. Any

frayed cable with broken wires should be replaced im-

mediately. Always replace the cable with the same or

equivalent type recommended by the manufacturer. The

equivalent types must have the same pull force, quality,

arrangement parameters and wire performance.

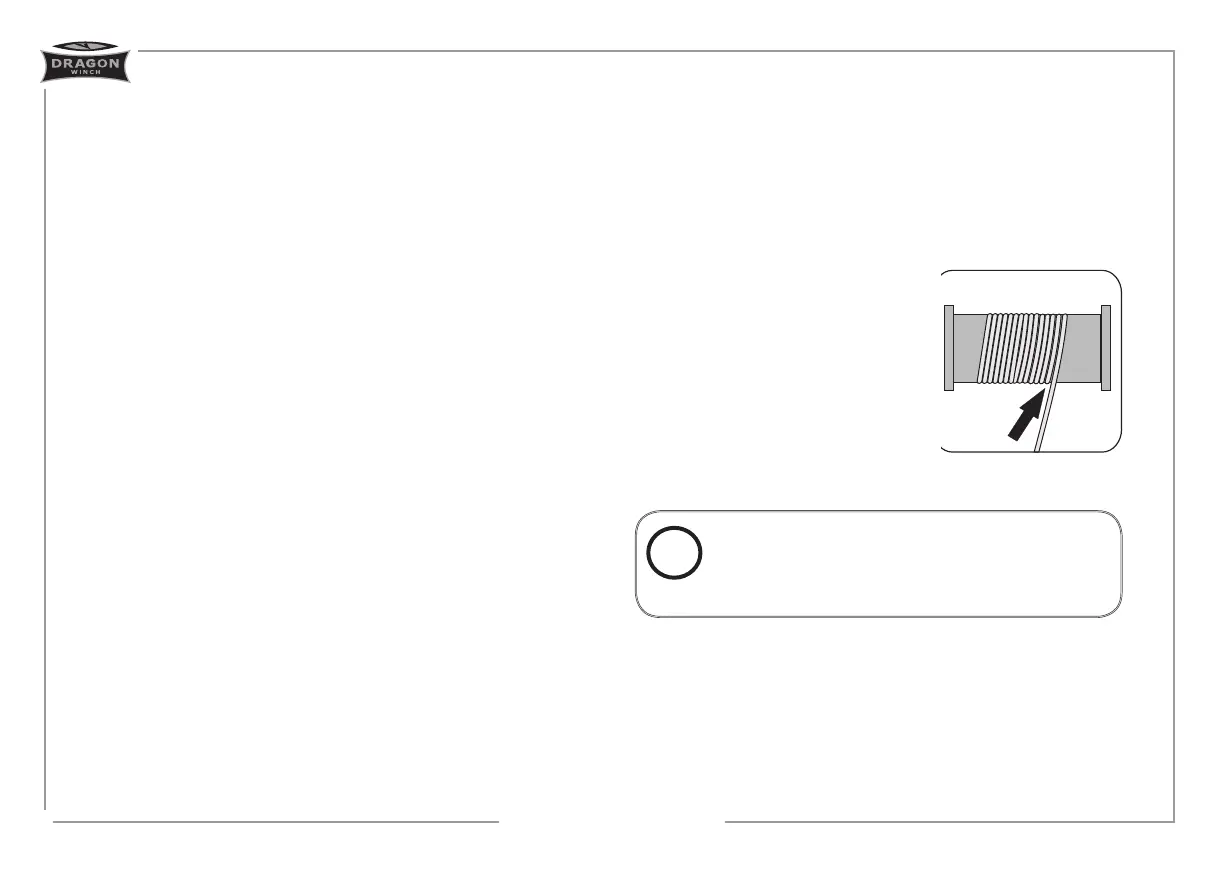

Pay attention to the correct direction of cable winding.

The cable must be wound on the underside of the winch

drum (between the mounting plate and the drum). Wrong

direction of cable winding may cause serious damage to

the winch.

The cable must be wound evenly, fake to fake, on the

winch drum in such a way that it does not cause the cable

to build up in one place or jam it between the lower lay-

ers. Improper winding of the cable signicantly reduces

the efciency of the winch and may lead to damaging

the equipment. In such cases, unwind the cable and start

winding it again.

After work, the cable should be

pulled (laid on the drum) with no

load. Hold the tightened cable in

one hand and the winch remote

controller the other.

For your own safety, during wind-

ing keep a minimum distance of

1.5 m from the winch.

The working life of the cable is directly dependent on how

it is used and stored.

It is not recommended to repair the cable. Any damaged

cable should be replaced with a new one.

ATTENTION

Do not use the winch cable as a tow-rope. Use

only the winch while pulling the load. Do not

“boost” the winch with the vehicle drive.

!

Loading...

Loading...