13

DM-5S

DM-5

DM-5N

DM-15

DM-50

DM-150

DM-500

DM-1500

DM-15HP

DM-50HP

DM-150HP

SP DM5S 101

SP DM5 101

SP DM5N 101

SP DM15 101

SP DM50 101

SP DM150 101

SP DM500 101

SP DM1500 101

SP DM15H 101

SP DM50H 101

SP DM150H 101

12

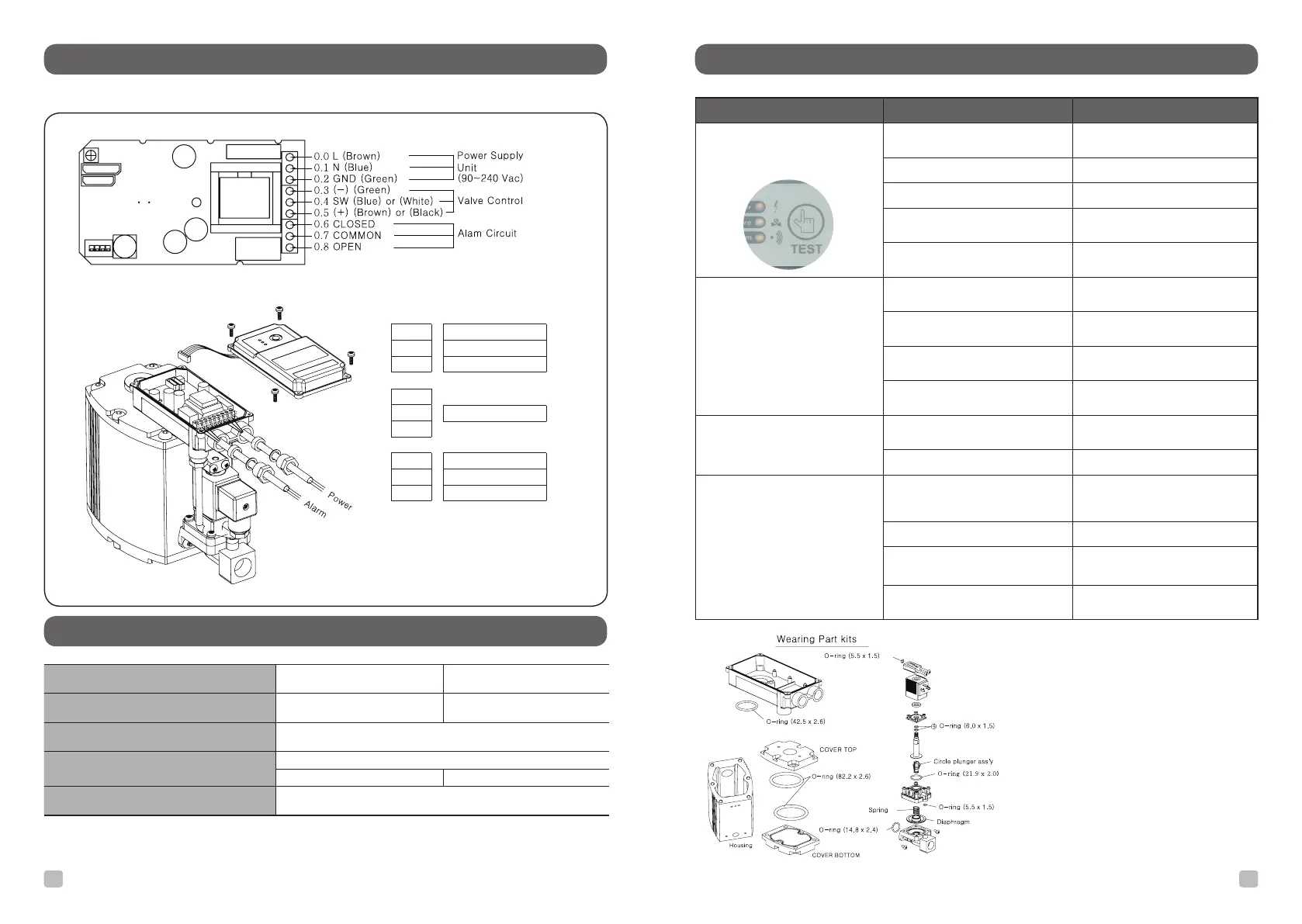

ELECTRICAL INSTALLATION

ELECTRICAL DATA

MAINTENANCE

0.0

0.1

0.2

0.6

0.7

0.8

0.3

0.4

0.5

Phase

Neutral

Ground

Normally closed

Common

Normally open

24 VDC

Power Voltage 90 ~ 240/ 24/ 48 Vac 24 / 48 Vdc

Max, Power input P < 2.0 VA P < 2.0 W

Recommanded cable jacket diameter Ø 5.8 ~ 8.0 mm

Cable cross-section and fuse protection

3 x 0.75 mm

2

/ 5 x 0.25 mm

2

0.5 A 100 mA

Contact loading relay or out 260 Vac - < 1.0 A

▶ The emergency relay will be activated when there is no operation pressure (0.8 bar) or with an error signal,

switching the system to the alarm mode

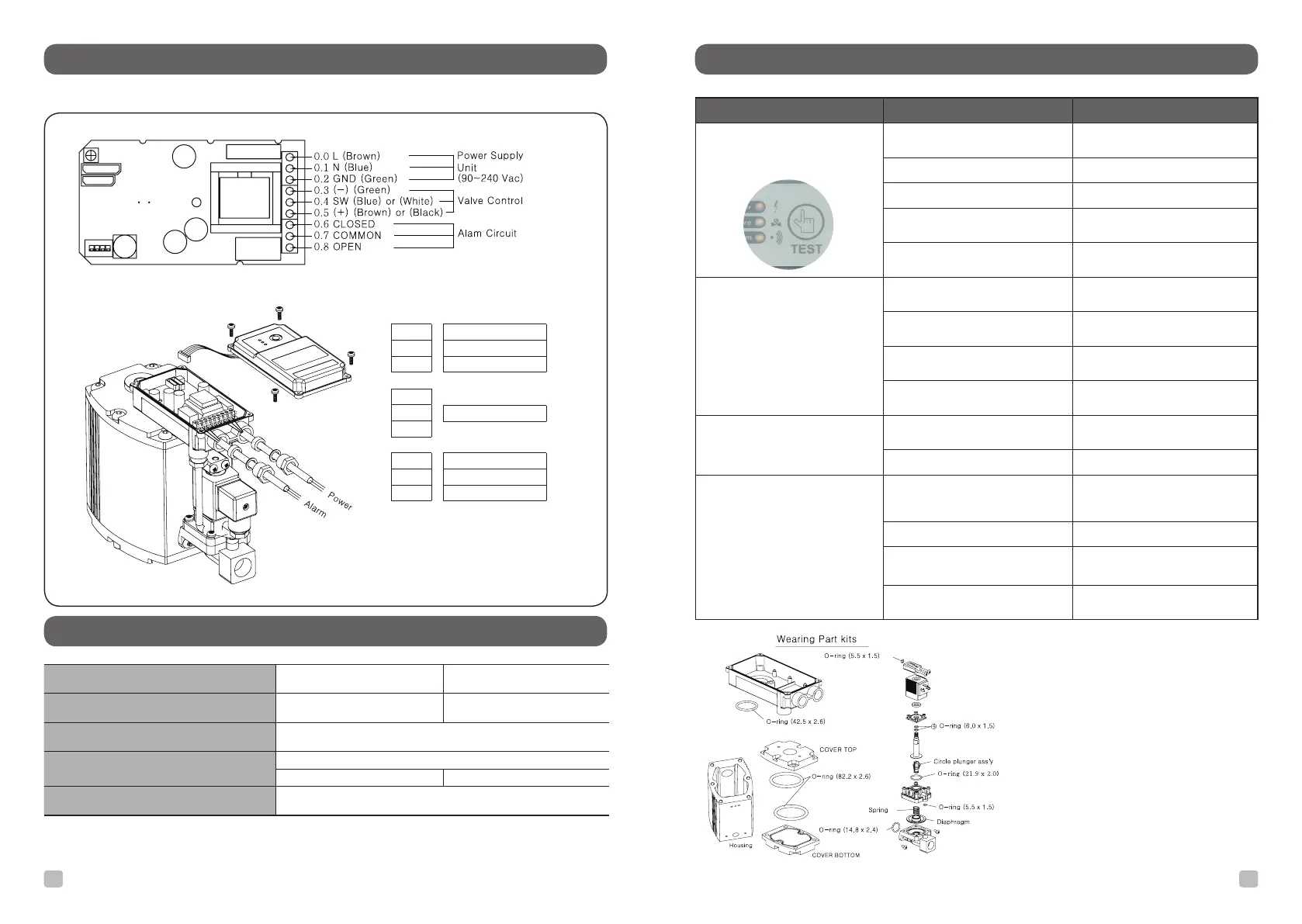

Trouble shooting Factor Solution

▶ No discharge of condensate

with the Test button

※ The feed line or the discharge

line is closed or blocked.

Check these lines.

※ Defective PCB Replace the PCB.

※ Defective solenoid valve Replace the solenoid valve.

※ Worn parts

Replace the worn parts

(Wearing part kits)

※ Pressure is lower than 0.8 bar Check the operation pressure.

▶ Condensate only discharged

when the Test button is pressed

and held

※ Insufficient pipe slope with

the feed line

Add slop to the feed line, or install

a vent line.

※ The pipe length for feed line

is too long

Install an air vent line

(see Installation Method)

※ Overload due to excessive

condensate

Select a correct model for the

volume of condensate.

※ Detection disabled by excessive

contamination on the sensor tube

Clean the sensor tube.

▶ Power lamp not lit

※ Power not connected.

Check the rated voltage.

Check the cable connection.

※ Defective PCB Replace the PCB

▶ Continuous air discharge from

the valve

※ The lower part of the diaphragm

is contaminated by foreign materials

(scale etc)

Remove foreign materials.

※ The 'control air line' is blocked. Remove foreign materials.

※ Poor operation due to foreign

materials inside the solenoid valve

Clean the valve.

※ Worn parts.

(Diaphragm. Plunger etc)

Replace the worn parts.

▶Clean the housing and valves 1-2 times a year.

▶Check wearing parts once a year.

▶Wearing parts

Power

Valve

Alarm

Loading...

Loading...