20

fig 20

Recalculating the Constant

It is especially important in arable situations to

check the rolling circumference of the tyre when

in the cultivated area to be sown, and if necessary,

recalculate the constant and hence the number of crank

turns.

If there is a significant difference at that time from the figure

used for calculations in this manual (Fig 20), the constant

should be recalculated and hence the crank turns for those

particular conditions.

Note - If a significant difference is found in the rolling

circumference the H1 setting should be adjusted on the

hectaremeter. Refer P 24.

1 To recalculate the constant due to altered conditions or

specific requirements use the formulae in Fig 20.

2

To obtain the rolling circumference of the tyre 1/2 fill the

seed/fertiliser boxes or simulate

this loading.

Mark the tyre of the drill at 90

0

to the

ground and the point of contact with

a mark on the ground. Move the drill

forward 3 revolutions until the mark

on the tyre is again at 90

0

to the

ground. Measure the distance along

the ground and divide by 3 to give

the rolling circumference of the tyre.

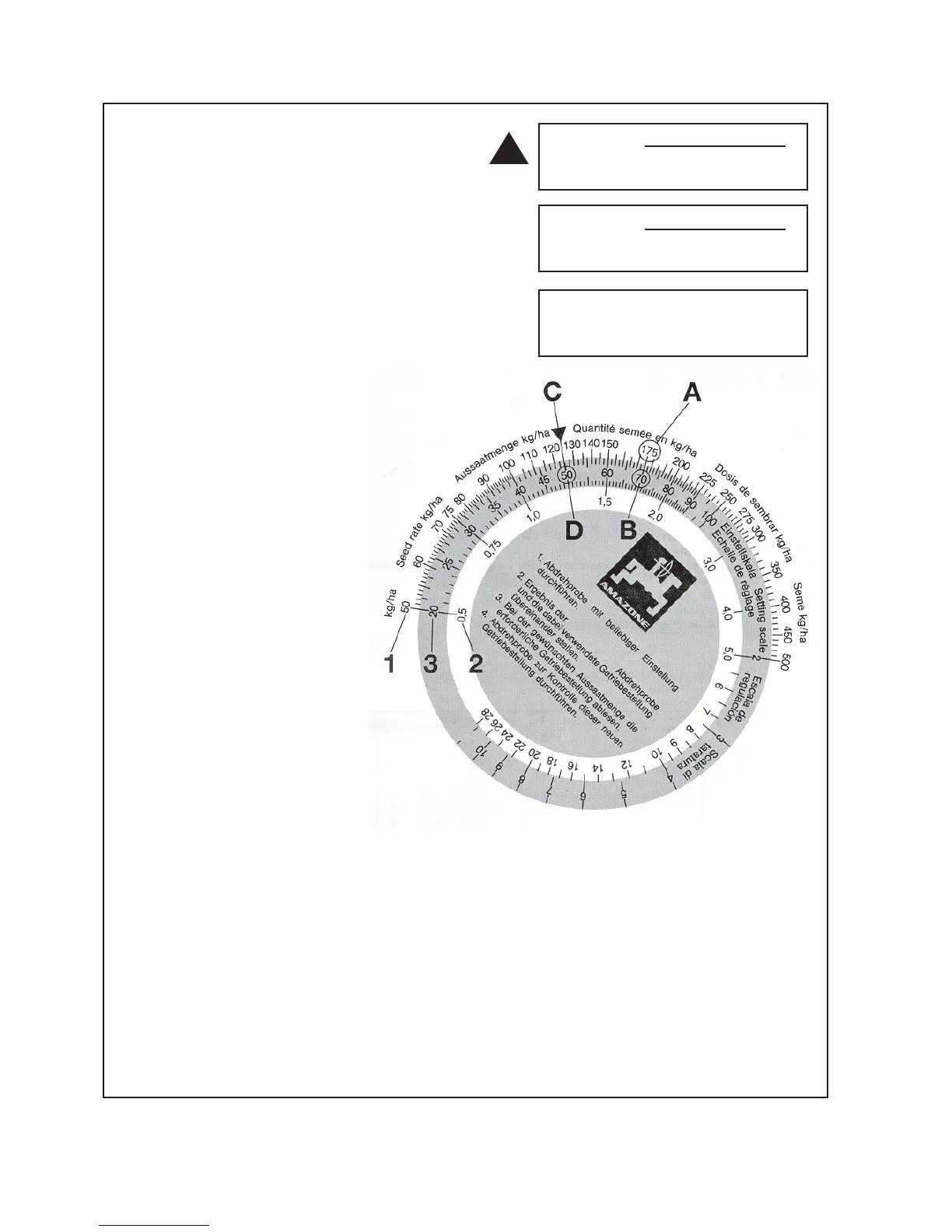

Use of Seed Rate

Calculator

Determining the gear box

scale setting using the

calculator.

Usually the first calibration test yields

a different seed rate. However with

the value determined from the first

test it is possible to determine the

correct gearbox setting with the aid

of the enclosed disc calculator, Fig

21. The disc calculator consists of

3 scales. An outer white scale (Fig

High Speed

=

1.667

Constant

Rolling Circumference

of Tyre

Low Speed

=

1.038

Constant

Rolling Circumference

of Tyre

Rolling Circumference

used for calibration was... 3.76metres

(10 ply tyre)

Setting Example (Desired seed Rate 125kg/ha)

1 From the calibration procedure (described on P 17-19) at a gearbox lever

setting of “70” a seed rate of 175 kg/ha was obtained.

2 Turn the inner disc until the measured seed rate of 175kg/ha (Fig 21/A) is in

line with the related actual gearbox setting of “70”.(Fig 21/B)

3 Read off from the disc rule the necessary gearbox setting for the required

seed rate of 125kg/ha (Fig 21/C) In this example the correct setting is “50”

(Fig 21/D)

4 To be on the safe side the new gearbox setting can be checked by another

calibration test.

!

Loading...

Loading...