Dyna-Flo Control Valve Services Ltd.

Edmonton, Alberta, CANADA

Website: www.dynaflo.com

Phone: 780

• 469 • 4000

Toll Free: 1 • 866 • 396 • 2356

Fax: 780 • 469 • 4035

Model

DFC Valve Actuator

Operation, Parts and Instruction Manuals

Instruction Manual May 2007

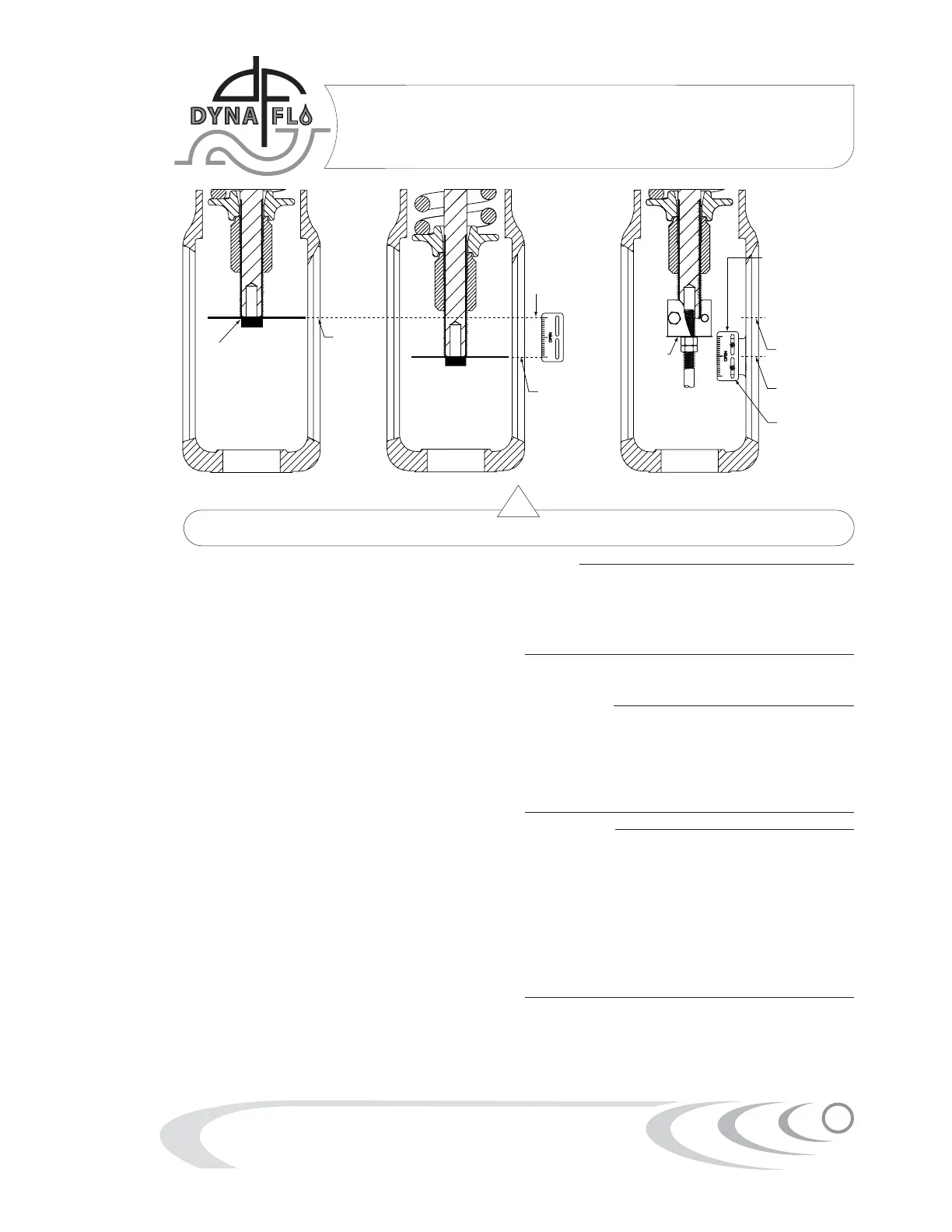

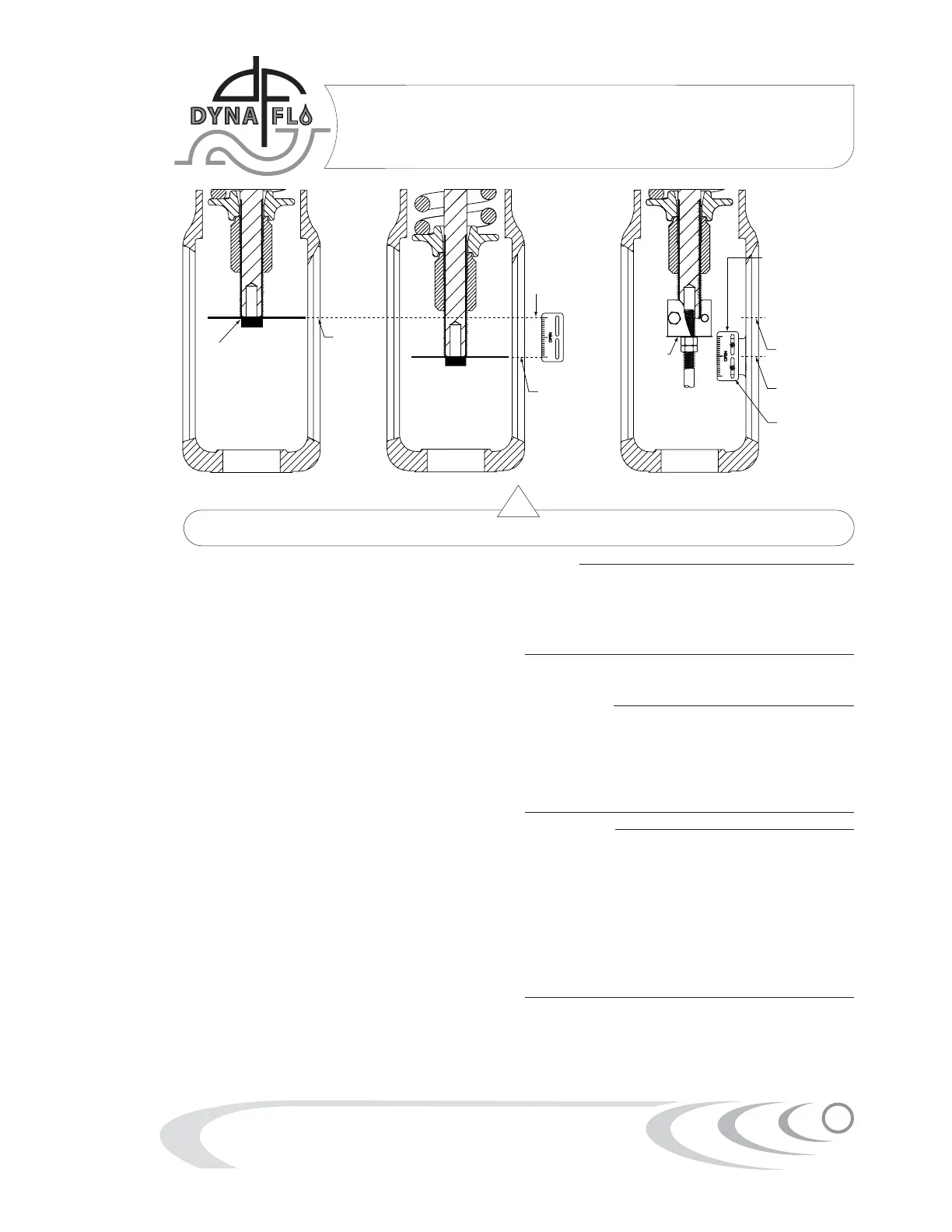

5

Rated Valve

Travel Scale

(Key 24)

Mark Upper

Bench Set

Loading

Pressure

Mark Lower

Bench Set

Loading

Pressure

Magnet/Ruler

Combination Setup

Travel

Indicator

Disk

(Key 27)

Travel Scale Adjusted

To Coincide With The

Travel Of The Travel

Indicator Disk After

Actuator Has Been

Mounted To Valve

Lower Bench

Set Loading

Pressure Mark

Upper Bench

Set Loading

Pressure Mark

*Note: Distance

of Travel Should

Match Specification

Given on Name Plate

(Key 33)

Figure 3 Bench Set Spring Adjustment Diagram

For Push Down to Close Valves

1 Apply the upper bench set loading pressure

plus 5 Psi (34 kPa) to the actuator and note

where stem travel stops, this should occur

when the travel stop (Key 10) encounters the

upper casing (Key 5). The intent is for the travel

stop to contact the upper casing at the exact

time the upper bench set loading value is

reached. Apply 5 Psi (34 kPa) above and below

the upper bench set value to verify this.

(Example: for a 10-30 bench set the travel stop

should contact the upper casing at exactly 30

Psig) If stem (Key 3) travel stops before or

after the upper bench set value, the spring

adjuster (Key 21) will need to be adjusted to

obtain the proper bench set. You may need to

relieve pressure to the actuator in order to

adjust the spring adjuster. Turning the spring

adjuster up (towards the top of the actuator)

will increase the bench set pressure.

2 Once the upper bench set pressure has been

set, use a magnet or piece of tape to attach

a piece of metal or ruler to the bottom of the

actuator stem (Key 3) to use as an indicator

arm. Make a mark to indicate the stem position

at the upper bench set pressure (See Figure 3).

Make sure the travel is fully extended.

3 Adjust the gauge to the lower bench set

pressure and mark the actuator stem position.

The measurement between the upper and

lower bench set marks should equal the travel

indicated on the name-plate within 1/16” (1.6 mm).

! Note !

If these steps do not allow you to reach

the proper bench set pressure then an

incorrect or damaged spring may be the

problem. Contact your Dyna-Flo Sales

Office for more information.

Mounting: Actuator to Valve

! CAUTION !

During mounting the actuator stem and

valve stem could come into contact with

each other. Ensure that the valve stem is

pushed down before trying to install the

actuator, doing this will help to protect

the stem threads from getting damaged.

! CAUTION !

It may be necessary to apply loading

pressure to the actuator temporarily to

move the actuator stem and allow for

more clearance between it and the valve

stem. Use extreme caution when moving

the pressurized actuator; ensure that no

clothing, hair, hands or tools come in

between the two stems or moving parts.

If loading pressure fails personal injury or

property damage may occur.

1 Make sure the valve is securely supported

using a vice or similar method before proceed-

ing. It is advised to place valve on a surface

that will be able to support the combined

weight of valve and actuator.

Loading...

Loading...