Dyna-Flo Control Valve Services Ltd.

Edmonton, Alberta, CANADA

Website: www.dynaflo.com

Phone: 780

• 469 • 4000

Toll Free: 1 • 866 • 396 • 2356

Fax: 780 • 469 • 4035

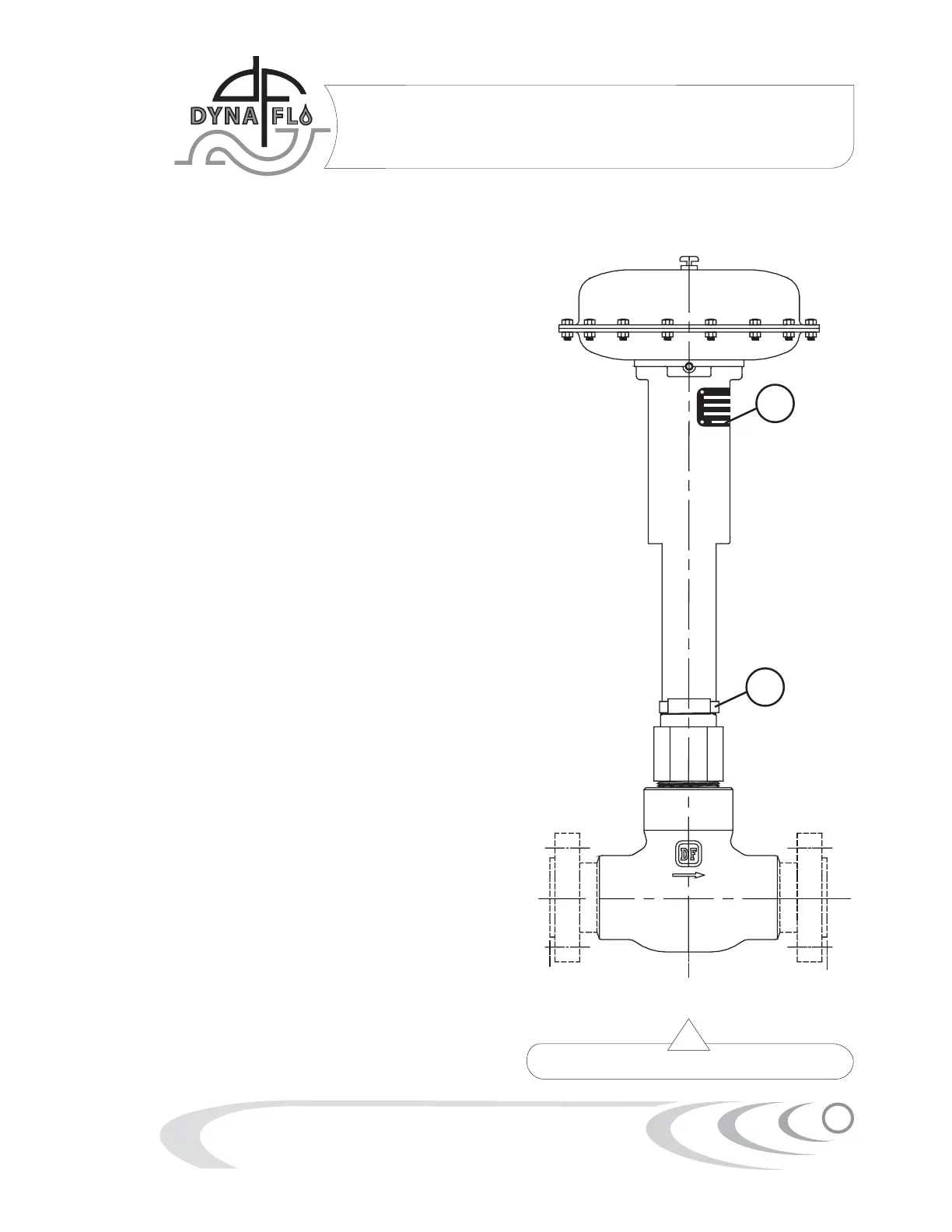

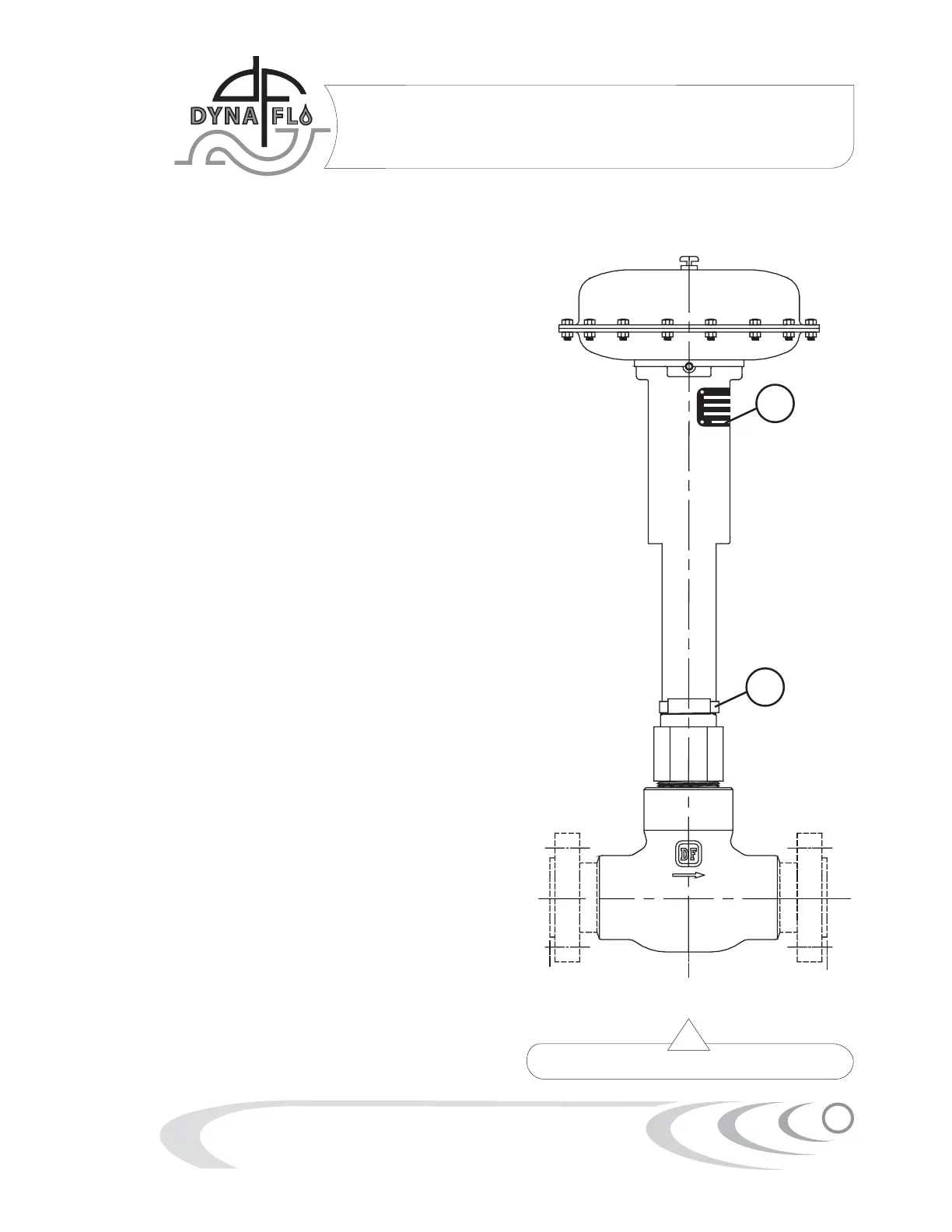

Model

DFC Valve Actuator

Operation, Parts and Instruction Manuals

Instruction Manual May 2007

9

Maintenance

(cont’d)

Upper Diaphragm Casing Assembly

1 Place the lower diaphragm plate (Key 6) into

the lower diaphragm casing (Key 4) and onto

the actuator stem (Key 3) as shown in

Figure 7. Insert the diaphragm (Key 7) into the

lower casing over the lower diaphragm plate

and align the holes on the diaphragm with

those of the lower casing.

2 Install the upper diaphragm plate (Key 8) onto

the actuator stem so that it rests in the dia-

phragm (for a two piece diaphragm plate

design both parts of the plate will need to be

installed Figure 6 Key 9).

3 Place the travel stop (Key 10) over the actuator

stem so that it rests on the upper diaphragm

plate. Coat the threads of the hex head bolt

with anti-seize and thread it into the top of

the actuator stem (Key 3), tighten the hex

head bolt completely making sure that the

holes on the diaphragm still align with those of

the lower casing (Refer to Torque Chart on

Page 11).

4 Lift and place the upper diaphragm casing (Key

5) onto the top of the actuator, make sure that

the holes of the upper casing align with those

of the lower casing (Key 4) and diaphragm

(Key 7). Install the casing cap screws (Key 18)

into the casings, Do Not coat the cap screws

with anti-seize. Thread the nuts (Key 19) onto

the casing cap screws, Do Not over tighten the

cap screws refer to Torque Chart on Page 11.

Tighten the casing cap screws in a crisscross

pattern to half required torque and in the

same pattern completely tighten cap screws to

full torque. In a circular pattern re-tighten the

casing cap screws (Key 18) to full torque.

5 Refer to Bench Setting Actuator portion of

manual to complete the actuator assembly.

32

33

Figure 5 Actuator & Valve Mounting Diagram

Loading...

Loading...