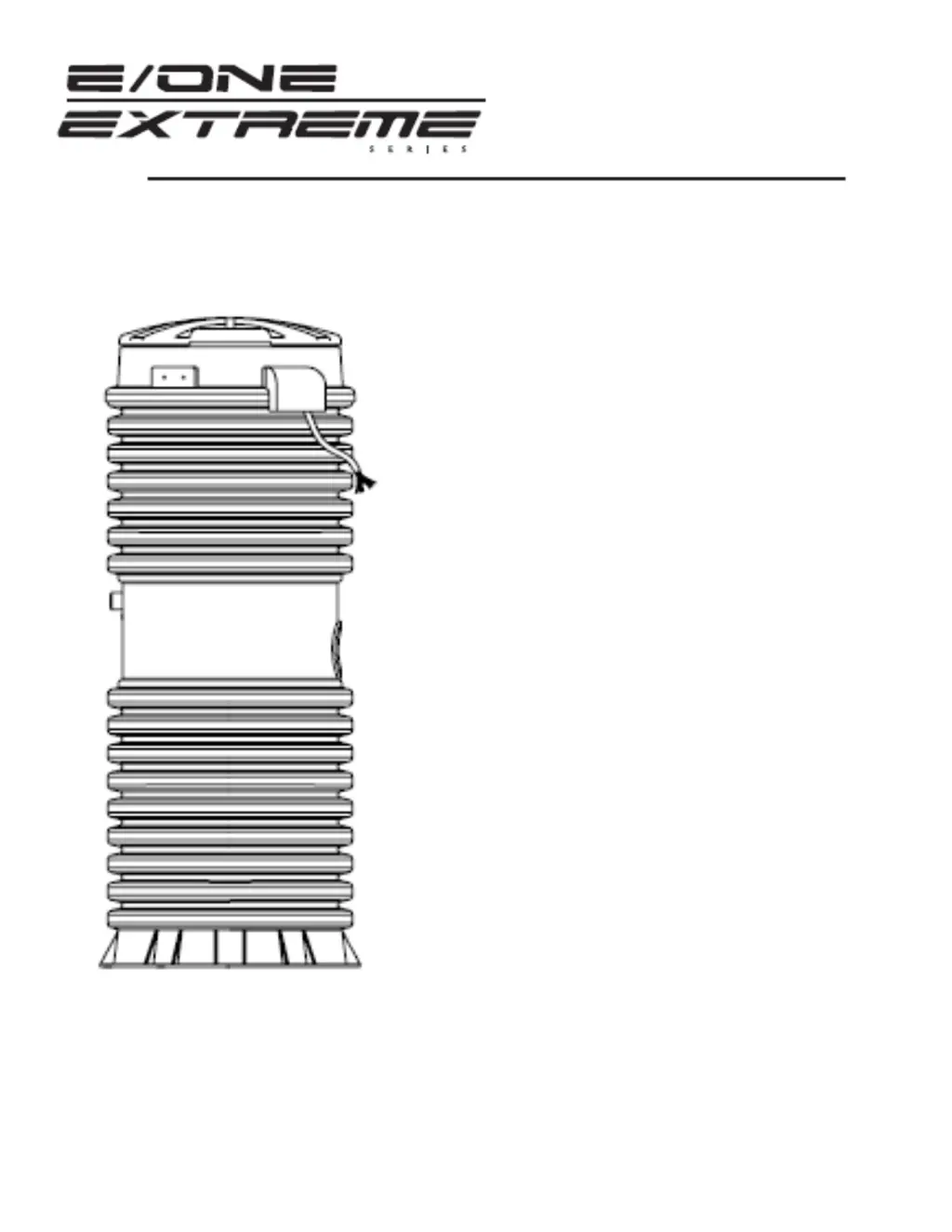

Why E-one Water Pump is not operating and the alarm is on?

- EelizabethlynchJul 31, 2025

If your E-one Water Pump is not operating and the alarm is on, there could be several reasons. First, check the voltage at the alarm panel and ensure it matches the voltage listed on the pump's nameplate, staying within a 10% range (216V to 264V). If you're using 208V, you'll need a buck boost transformer to increase the power to 240V. Another potential cause is a plugged equalizer tube, so inspect it to ensure it's not crimped or pinched. Also, check the tank for sufficient fluid to operate the pump. The pump operation depends on the water level inside the tank. Insufficient fluid may indicate a problem with the alarm wiring, alarm sensing line, or alarm switch. See Chapter 7 – Level Sensor.