17

Sliding Hammer

Puller

Mark Trunnion

and Housing

Shims

O-ring

O-ring

Shims

Trunnion Bearing

Cone

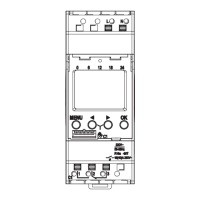

Figure 19

47 Mark the motor housing and the trunnions so they

can be reinstalled in the same locations.

48 Repeat the following steps to remove each trunnion:

Remove the three hex head bolts that hold the trunnion

to the motor

The trunnion fits into the motor tightly; use a slide

hammer to loosen it. Screw the slide hammer into the

threaded hole in the trunnion. The sizes of the threaded

trunnion holes are listed below:

Remove the trunnions and shims.

Important: Keep the shims with each trunnion; they

must be reinstalled on the same trunnion during

reassembly. The shims pre-load the trunnion bearings.

Remove the o-ring from the trunnion, see figure 19.

49 If the trunnion bearings are damaged replace them.

A split blade bearing puller will be needed to remove the

bearing cone from the trunnion. Use a press to install

the new bearing cone.

50 Carefully remove the swashplate, cylinder barrel and

shaft through the mounting flange end of the housing.

Model Number Screw Size

33, 39, 46 3/8-16

54, 64 7/16-14

Major Repairs: Mounting Flange, Servo Pistons and Trunnions

Loading...

Loading...