20

Control Valve

Mount

Trunnion

O-ring

Shims

Shims

O-ring

Figure 24

72 Install the trunnion bolts and tighten them to the

specified torque given below:

69 Carefully, put the swashplate, cylinder barrel, and

shaft into the motor housing. Be sure the feedback

linkage is by the control valve mount.

70 Lubricate and install a new o-ring on each trunnion.

71 Install the trunnions and shims in their original

locations.

Strike the Trunnion to Free-up

Swashplate Movement

Spring

Compression

Scale

Model Number Trunnion Bolt Torque

33, 39 28 lb-ft [38 Nm]

46, 54, 64 44 lb-ft [60 Nm]

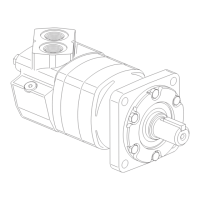

73 After the bolts are torqued strike one of the trunnions

to free up the swashplate’s movement.

74 Measure the swashplate breakaway force with a

spring compression scale. Attach the scale to the

feedback linkage as shown in figure 25. A swashplate

breakaway force of 2 to 5 lb [,9 to 2,3 Kg] is required.

Add or subtract trunnion shims as needed.

Figure 25

Important: The trunnion shims on

each side of the motor should be

equal thickness. The maximum

allowable difference between the

sides is .010 in. [,3 mm].

2

2

Major Repairs: Trunnions and Servo Pistons

Loading...

Loading...