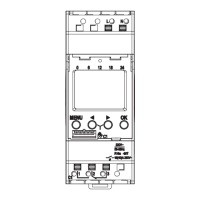

27

Bolt (4)

Back-up Ring

O-ring

Sq. Cut Seal

Valve Block

Hose Fittings

Hose Ass'y

Figure 37

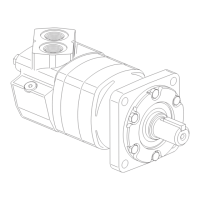

Control Valve

Gasket

Feedback

Linkage

Figure 38

104 Install new o-rings and back-up rings in the grooves

around the high pressure ports as shown in figure 37.

Install a square-cut seal in the groove around the low

pressure port. Use petroleum jelly to hold these sealing

rings in place while the valve block is installed.

105 Position the valve block on the motor. Install the

four hex head bolts and tighten them to 28 lb-ft [38 Nm].

106 Tighten the high pressure relief valves to 25 lb-ft

[34 Nm].

Tighten the low pressure relief valve, and shuttle valve

plugs to 80 lb-ft [108 Nm].

Tighten the gauge port plugs and control pressure hose

fittings, if used, to 17 lb-ft [23 Nm].

107 Connect the control pressure hose between the

motor housing and valve block fittings, if used. Tighten

both ends to 7.5 lb-ft [10 Nm].

108 Reposition the motor so the control valve mount is

on top.

109 Place a new control valve gasket on the motor.

110 Connect the feedback linkage and position the

control valve on the motor.

Important: When the control valve is positioned on the

motor make sure the feedback linkage points towards

the end cover.

111 Install the six hex head bolts and tighten them

finger tight.

112 Move the control lever back and forth; it should

move freely in both directions and self-center. If it

doesn’t, recheck the feedback linkage.

113 Tighten the six hex head bolts to 16 lb-ft [22 Nm].

Note: The control pressure hose is now obsolete. Poor

motor control characteristics may be experienced when

the motor gets control pressure from the valve block. It

is best to run a separate control pressure line from the

charge pump to the motor. If possible re-plumb the

application so the control pressure hose is no longer

used. Be sure to plug the port in the valve block.

End Cover, Valve Block and Control Valve

Loading...

Loading...