Page 4

This document is proprietary. No disclosure, reproduction or use of any part thereof may be made without the expressed written

permission of Ebbco Inc. or its subsidiaries.

Section 1: Introduction

1.1 Introduc

tion

This following technical manual provides instruction on installation and operation of the Garnet

Removal System manufactured by Ebbco Inc. With correct maintenance and system operation the Garnet

Removal System will keep garnet form building up in the waterjet cutting machines work tank and will

increasing production by eliminating down time for tank shoveling. The Garnet Removal System will

require some assembly on site. This will include sweeper package assembly and connecting the Garnet

Removal System to the waterjet cutting machines work tank. The Garnet Removal System is

manufactured using quality materials and by highly experience production staff. The Garnet Removal

System is tested in Ebbco's test department to ensure that it meets the specifications required by the

customer. The Garnet Removal System is inspected and all test data documented prior to shipment.

1.2 Sequence of operation.

This system is designed to keep garnet from building up in the cutting table. The method used to

achieve this is the use of agitation on the bottom of the tank by water pumped through eductor header

nozzles located and directed in engineered locations. The garnet thus stays in suspension due to the

agitation and is carried out of the tank by way of the heavy duty centrifugal pump. It is pumped through a

centrifugal separator, which concentrates the garnet in the fluid stream and separates it for disposal into

an abrasive bag hopper. Excess water that comes out of the separator when it purges the solids from the

collection chamber is decanted from the hopper, returning to system tank.

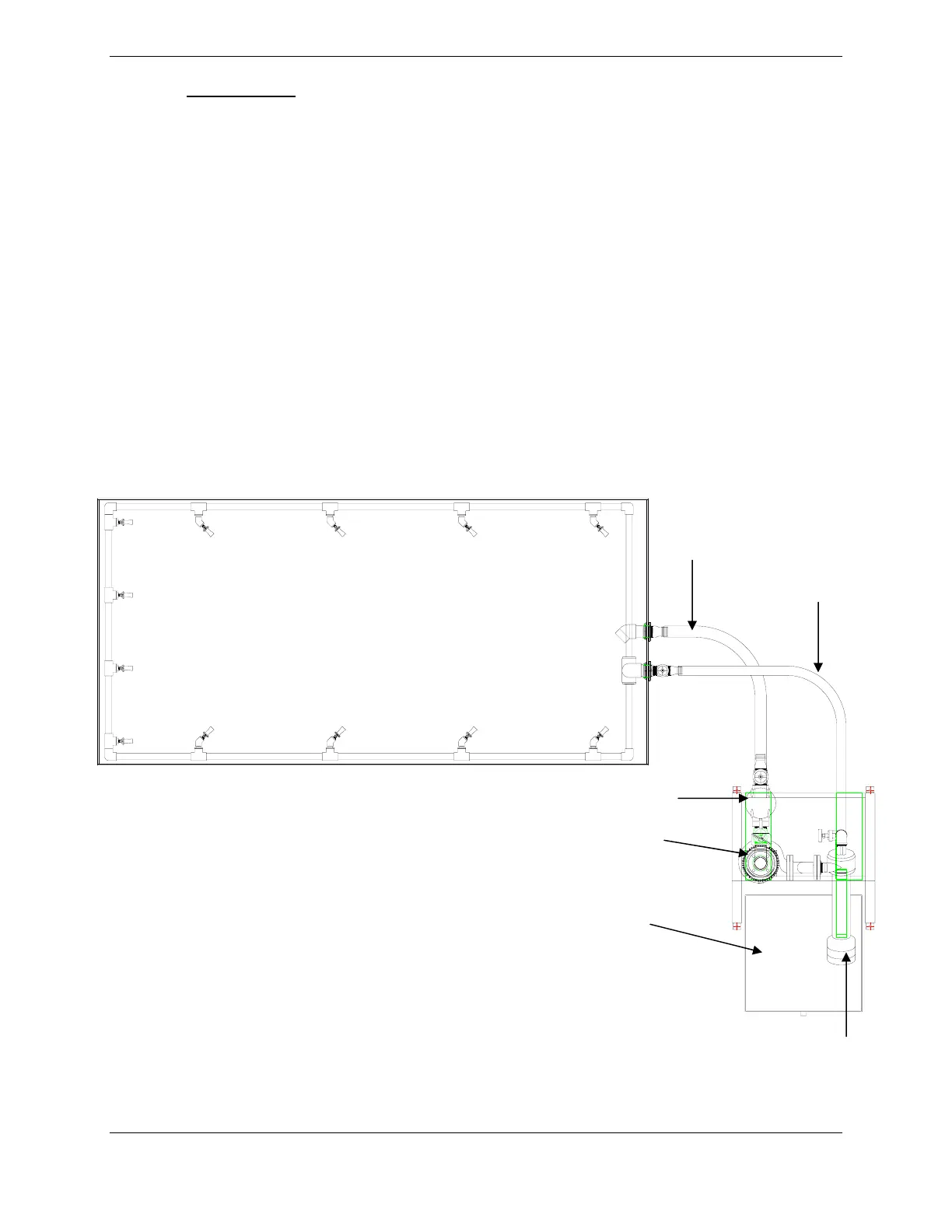

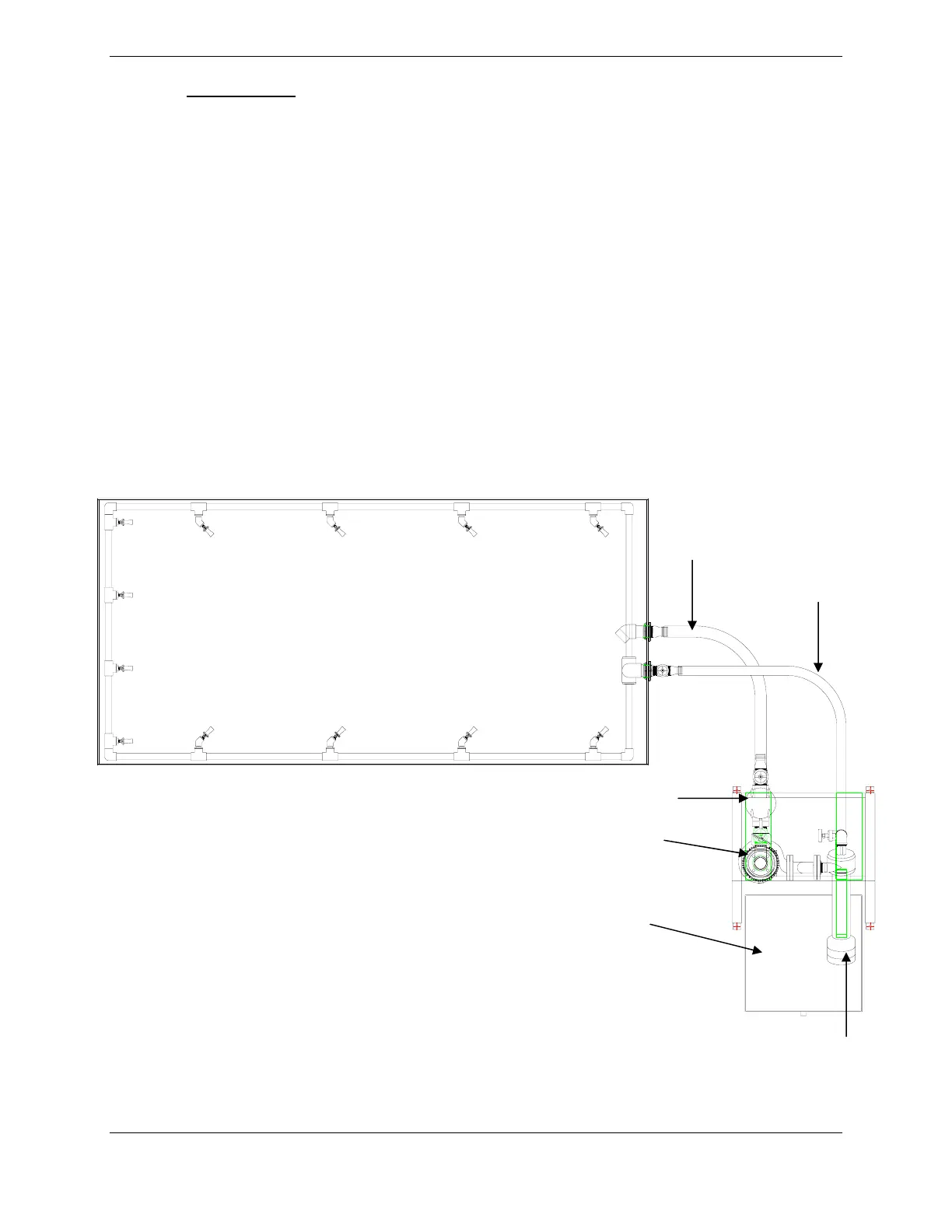

SYSTEM TANK

Note: This is a generic model of the layout of Ebbco’s

GRS-0250-B-CC-MC system. Your individual

components (# of eductors and their positioning, for

example) and system positioning may vary depending

on your individual needs. Please see the Parts List

(Section 6) for a list of your individual components.

Strainer Basket

Separator

Pump

Abrasive

Bag Hopper

Centrifugal

separator

Suction

line

Discharge line

Loading...

Loading...