SERVICE INFORMATION

PB-251

PB-255ES

ES-255ES

4

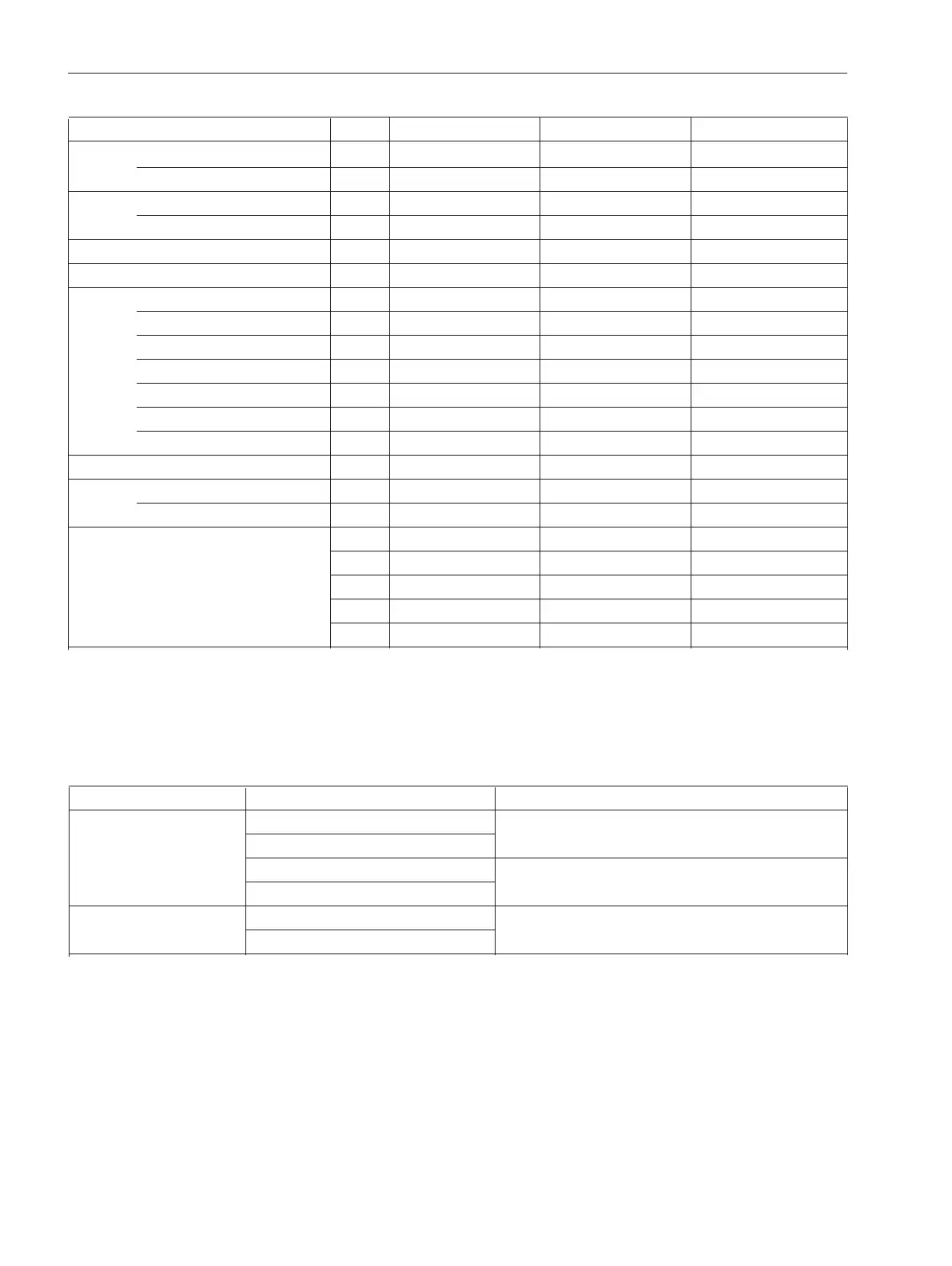

1-3 Torque limits

Descriptions

Size

kgf•cm

N•m

in•lbf

Starter Starter pawl M 8* 130 - 150 13 - 15 115 - 130

system

Starter case M 5 40 - 55 4.0 - 5.5 35 - 50

Ignition Ignition coil M 4 35 - 45 3.5 - 4.5 30 - 40

system

Spark plug M 14 130 - 170 13 - 17 114 - 150

Fuel Carburettor insulator M 5 50 - 70 5 - 7 45 - 60

system

Carburettor M 5 30 - 45 3 - 4.5 25 - 40

Engine Crankcase M 5 70 - 110 7 - 11 60 - 95

Cylinder M 5** 70 - 110 7 - 11 60 - 95

Cylinder cover M 5 60 - 80 6 - 8 50 - 70

Cylinder cover with lead M 5 40 - 60 4 - 6 35 - 50

Engine mount M 4* 30 - 45 3 - 4.5 25 - 40

Muffl er M 5 70 - 80 7 - 8 60 - 70

Muffl er cover M 5* 30 - 45 3 - 4.5 25 - 40

Others Outer fancase M 5

†

20 - 40 2 - 4 17 - 35

Fan M 8 140 - 160 14 - 16 120 - 140

Fan hub M 8* 160 - 200 16 - 20 140 - 175

Regular bolt, nut and screw M 3 6 - 10 0.6 - 1 5 - 9

M 4 15 - 25 1.5 - 2.5 13 - 22

M 5 25 - 45 2.5 - 4.5 22 - 40

M 6 45 - 75 4.5 - 7.5 40 - 65

M 8 110 - 150 11 - 15 95 - 130

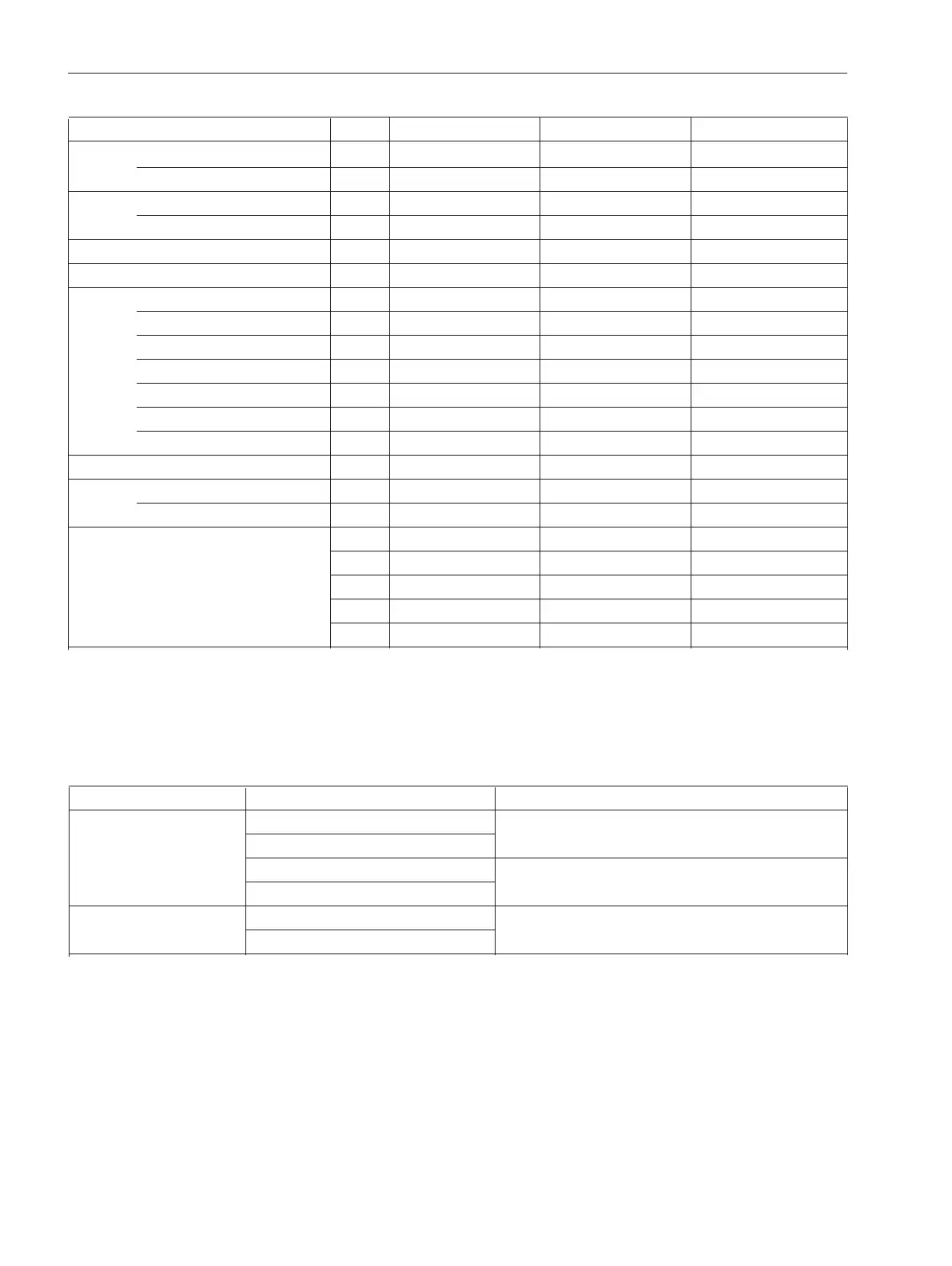

1-4 Special repairing materials

Material

Location

Remarks

Thread locking sealant Engine mount

Loctite # 242, ThreeBond 1324 or equivalent

Fun hub

Starter pawl

Loctite # 222, ThreeBond 1342 or equivalent

Muffl er cover

Grease Rewind spring

Lithium based grease or ECHO LUBE

TM

Starter centre shaft

* Apply thread locking sealant (See below)

** The torque differences among four bolts should not exceed 20 kgf•cm (N

•

m, 17in•lbf) on one cylinder or crank-

case.

†

Tapping screw

Loading...

Loading...