22

Maintenance and care

operating choke twice to clear air from carburetor chambers.

3. Check idle speed and reset if necessary. If a tachometer is

available, idle speed screw should be set to the specifica-

tions found on Page 26"Specifications" of this manual. Turn

idle screw clockwise to increase idle speed; counter clock-

wise to decrease idle speed.

Cooling system maintenance

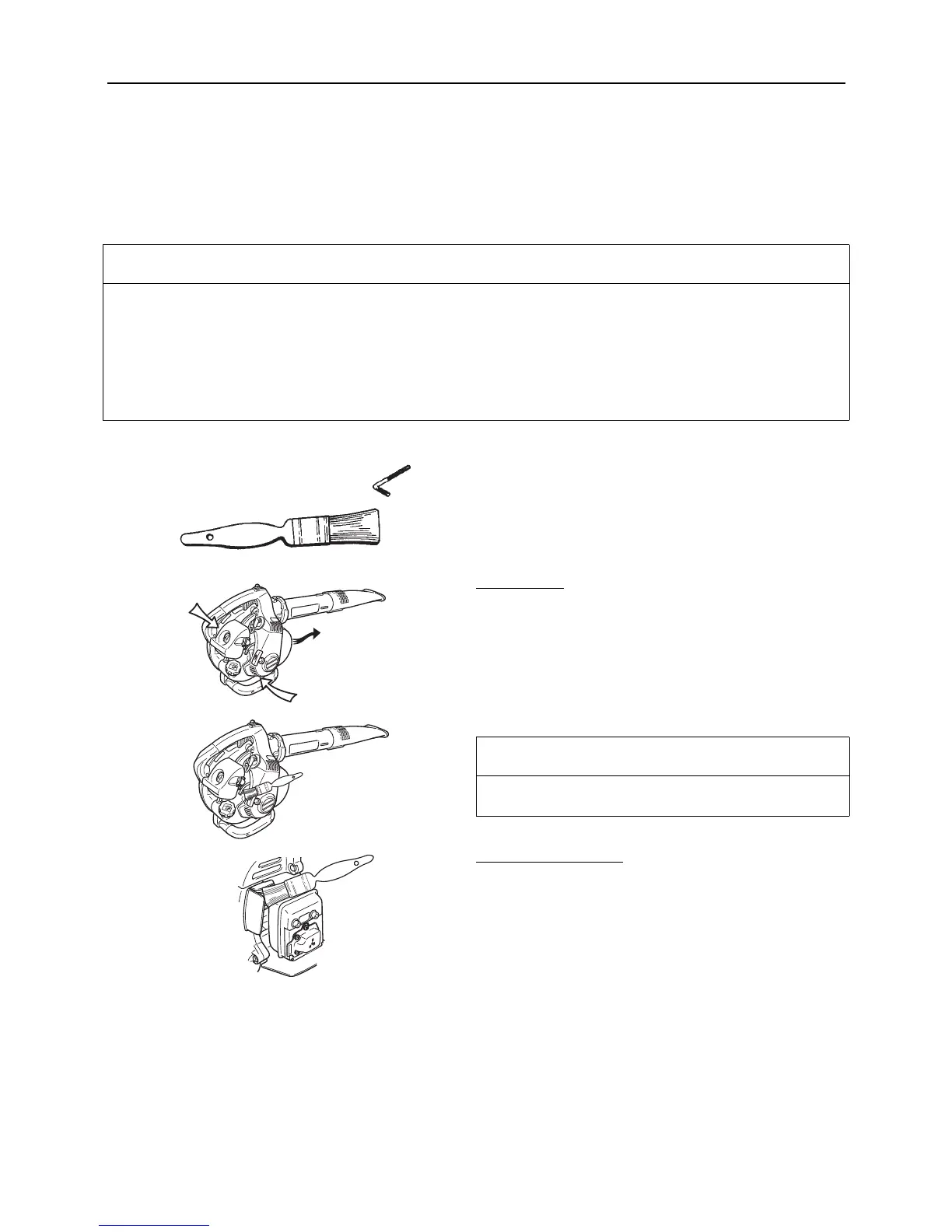

Tools required: 4mm x 130 mm (5") long hex wrench, cleaning

brush

Parts required: None, if you are careful.

Cleaning Grill

1. Brush accumulated debris from crankcase intake grill above

the fuel tank.

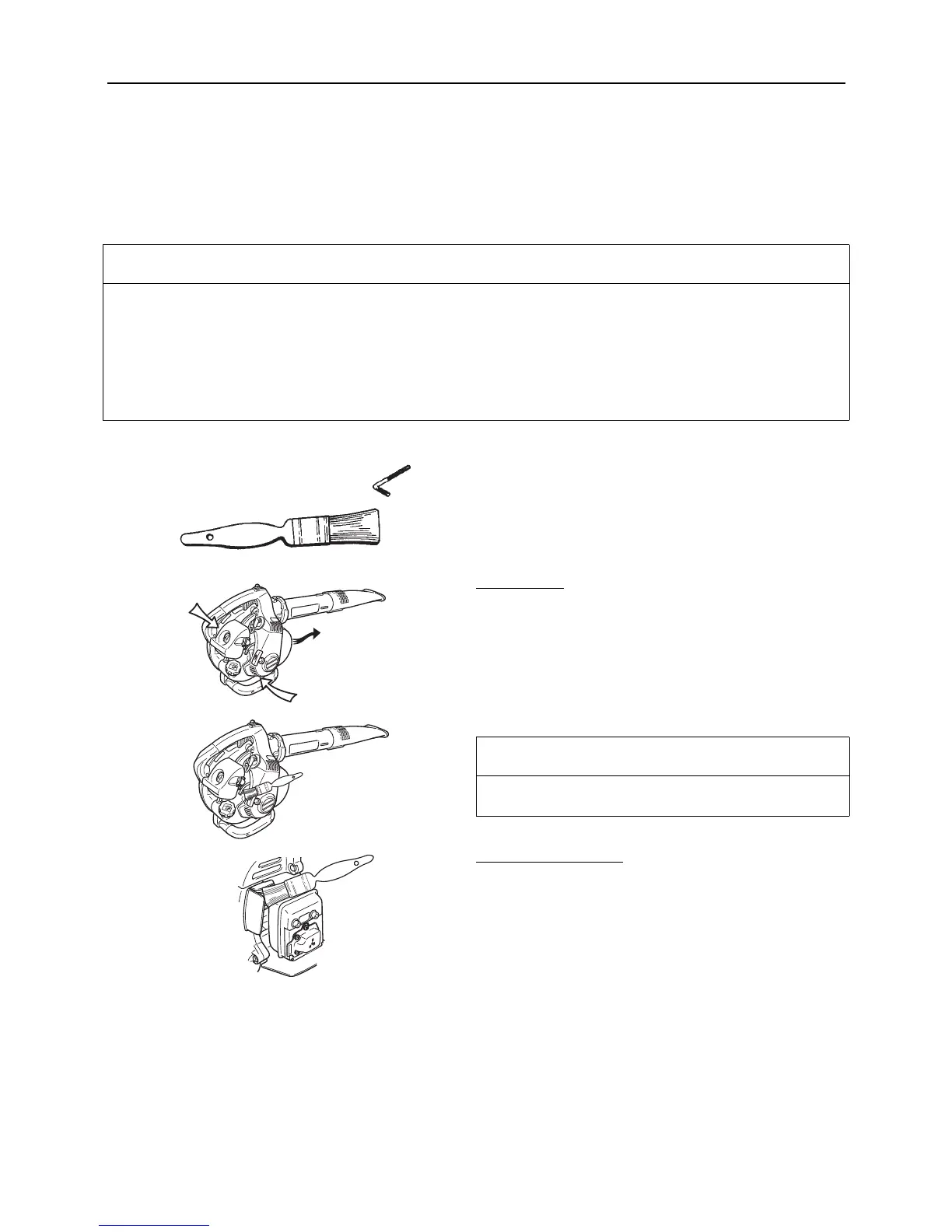

Cleaning Cylinder Fins

1. Remove engine cover (two screws), pull cover away from

engine. Clean cylinder fins to allow cooling air to pass freely.

2. Loosely reassemble engine cover with two screws.

3. Tighten all screws securely.

IMPORTANT

To maintain proper engine operating temperature, cooling air must pass freely through the cylinder fin area. This flow of air car-

ries combustion heat away from the engine.

Overheating and engine seizure can occur when:

Air intakes are blocked, preventing cooling air from reaching the cylinder,

or

Dust and grass build up on the out side of the cylinder. This build-up insulates the engine and prevents the heat from leaving.

Removal of cooling passage blockages or cleaning of cylinder fins is considered "Normal Maintenance". Any resultant failure

attributed to lack of maintenance is not warranted.

IMPORTANT

Do not over-tighten screws, otherwise mounting holes may be-

come stripped.

Loading...

Loading...