3

ASSUME 4-TON EQUIPMENT WITH 10" ROUND SMALLEST ZONE

1600 CFM

(EQUIPMENT)

– 400 CFM

(SMALLEST ZONE – NORMAL CFM )

= 1200 CFM NEEDED

SO, FROM THE ROUND DAMPER MAX CFM,

A 14" ROUND DAMPER SHOULD BE USED FOR BYASS.

EXAMPLE

2 -2.5 10"

3 -3.5 12"

4 -4.5 14"

5 14 -16"

UNIT SIZE ROUND DAMPER

(TONS) SIZE (INCHES)*

BYPASS DAMPER “RULE OF THUMB”

BELOW CHART ASSUMES 400 CFM PER TON *USE

NEXT SIZE UP ROUND BYPASS DAMPER FOR ANY

SYSTEM WITH A SINGLE ZONE LESS THAN 200 CFM.

A PROPERLY SIZED BYPASS DAMPER AUTOMATICALLY MAINTAINS CONSTANT PRESSURE INSIDE THE

SUPPLY AIR DUCT WHEN ZONES OPEN AND CLOSE. WHEN THE CORRECT SIZE BYPASS DAMPER IS

INSTALLED AND ADJUSTED ACCURATELY, IT WILL BE FULLY CLOSED WHEN ALL ZONES ARE CALLING

(NO AIR BYPASSING) AND WILL OPEN PROPORTIONATELY AS ZONE DAMPERS CLOSE.

RECTANGULAR CFM

*

SURFACE AREA IN SQ. FT.

=

(“HEIGHT” X “WIDTH”) / 144

NORMAL CFM =

(SURFACE AREA IN SQ. FT.*) X 600 FPM

MAX CFM =

(SURFACE AREA IN SQ. FT.*) X 900 FPM

6” 100 200

7” 150 250

8” 200 300

9” 300 450

10” 400 600

12” 600 900

14” 900 1400

16” 1400 2000

DAMPER NORMAL MAX

SIZE CFM CFM

ROUND CFM CHART

BYPASS - PRESSURE RELIEF

BYPASS SIZING

SELECT A DAMPER SIZE WITH A MAX CFM GREATER THAN THE CFM-NEEDED TO BYPASS. USE

THE FORMULA BELOW TO CALCULATE CFM NEEDED TO BYPASS AND THE ROUND DAMPER CFM

CHART TO CHECK MAX CFM.

TYPICALLY 400

CFM PER TON

USE A BYPASS DAMPER THAT

HAS LARGER “MAX CFM”

800 2

1200 3

1600 4

2000 5

EQUIPMENT AIRFLOW

CAPACITY IN CFM (HIGH SPEED)

CFM OF

SMALLEST ZONE

CFM-NEEDED

TO BYPASS

USE “NORMAL CFM”

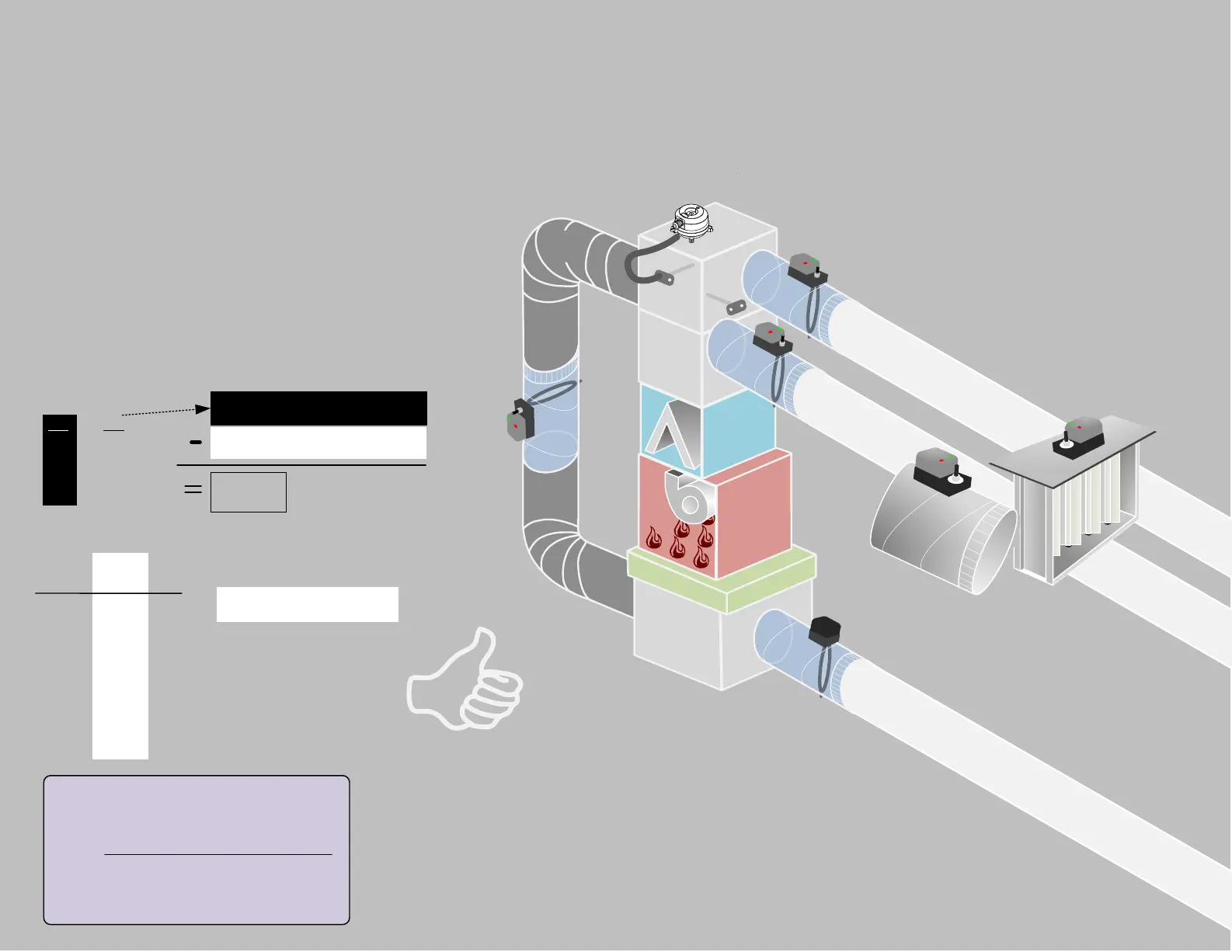

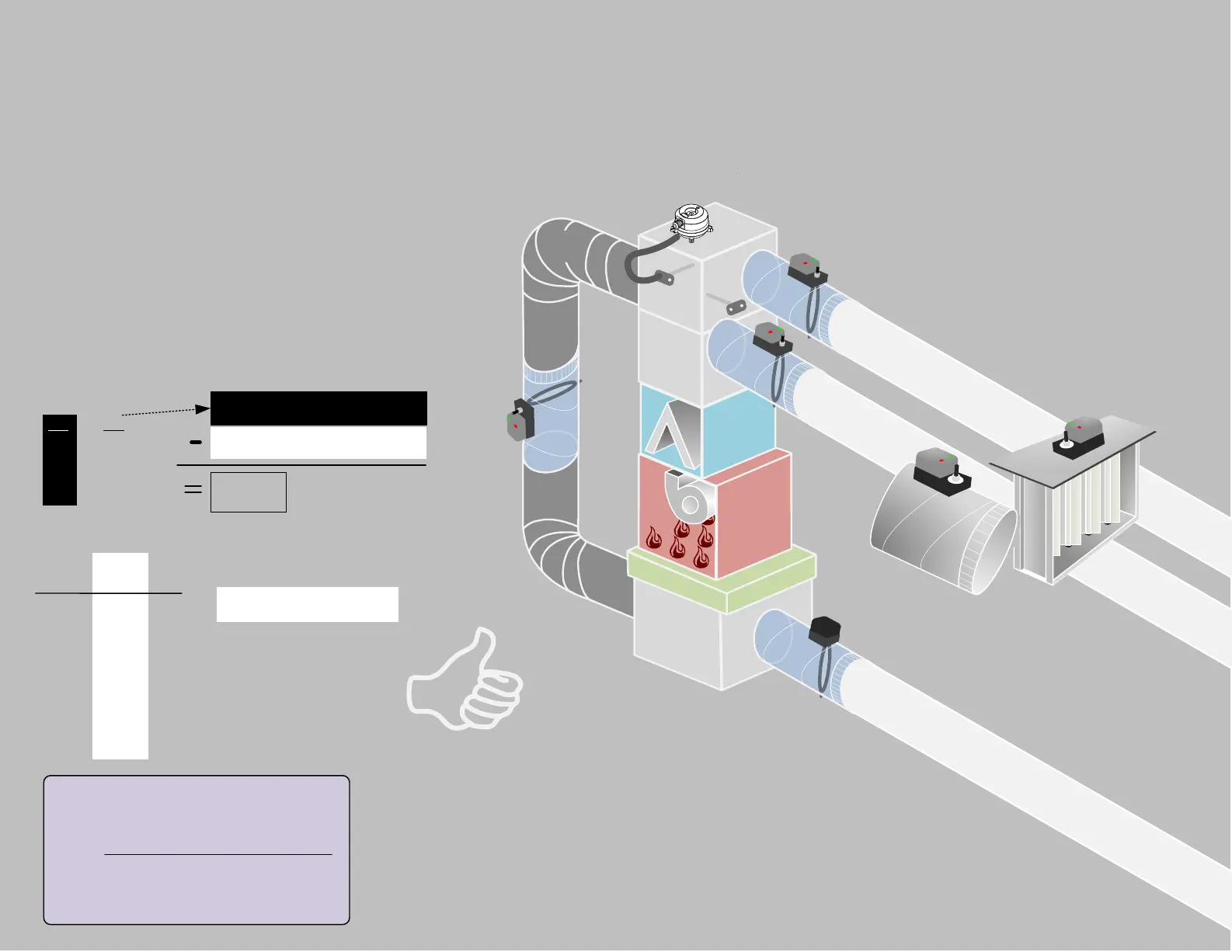

BYPASS

DUCT

RETURN AIR

F

ILTER

SUPPLY

AIR

EVAP.

COIL

(COOLING)

BLOWER

(FAN)

FURNACE

(HEATING)

FRESH

AIR

AIR NOISE

SHOULD BE ALWAYS BE MINIMIZED AND IN A ZONING SYSTEM WITH OPENING &

CLOSING DAMPERS IT CAN BE MORE CHALLENGING. INSTALL THE DAMPER AS

CLOSE AS POSSIBLE TO THE SUPPLY PLENUM TO PREVENT AIR NOISE

TRANSMISSION INTO THE CONDITIONED SPACE. TO MINIMIZE NOISE AND

MAINTAIN ADEQUATE THROW, SUPPLY AIR DUCT SYSTEM SHOULD BE DESIGNED

TO PROVIDE 600 TO 700 FPM VELOCITY AIRFLOW. THIS CAN BE ACHIEVED BY

PROVIDING LARGE ENOUGH DUCTS/DAMPERS TO SUPPLY THE VOLUME (CFM)

OF AIR NEEDED FOR THE ZONE. USE THE “NORMAL CFM” CHART TO CHECK

ROUND DUCT SIZE(S) THAT WILL ACHIEVE THIS VELOCITY.

►FOR ZONES WITH MULTIPLE DAMPERS, THE TOTAL ZONE CFM IS THE SUM OF

ALL THE DAMPERS “NORMAL CFM”

►FOR RECTANGULAR DUCT SYSTEMS USE THE RECTANGULAR CFM EQUATION

PROVIDED FOR “NORMAL CFM”

ZONE BALANCING

TO MAINTAIN OPTIMAL EQUIPMENT PERFORMANCE IN A TYPICAL ZONING APPLICATION, IT IS PREFERABLE TO DESIGN ALL ZONES TO BE

CLOSE TO EQUAL IN SIZE.(IN TERMS OF CFM). THIS DOES NOT MEAN THAT EVERY ZONE MUST HAVE EXACTLY THE SAME CFM REQUIREMENTS

BUT THE SYSTEM WILL WORK MOST EFFICIENTLY IF THEY ARE APPROXIMATELY THE SAME SIZE. FOLLOWING THIS GUIDELINE WILL MINIMIZE

THE AMOUNT OF PRESSURE RELIEF (BYPASS) NECESSARY. FOR MOST RESIDENTIAL ZONING INSTALLATIONS USING SINGLE SPEED

EQUIPMENT, AVOID CREATING MORE THAN THREE ZONES WITH NO ZONE SMALLER THAN 20% OF THE TOTAL EQUIPMENT CFM CAPACITY.

SMARTZONE DUCT SYSTEM

A ZONING SYSTEM CAN TYPICALLY USE THE SAME DUCT SIZING AS A TRADITIONAL SINGLE-THERMOSTAT SYSTEM IF THE PRESSURE RELIEF

IS INSTALLED CORRECTLY AND THE SYSTEM IS 4 OR LESS ZONES. TO MINIMIZE BYPASS AIR FLOW, INCREASE THE DUCT CAPACITY BY ONE

SIZE FOR EACH ZONE LESS THAN 25% OF THE TOTAL SYSTEM AIR FLOW CAPACITY AS SYSTEMS GET LARGER THAN 4 ZONES, IT MAY

BECOME NECESSARY TO INCREASE THE DUCT & DAMPER SIZES OF THE SMALLER ZONES (OR ALL THE ZONES) IN ORDER TO MINIMIZE THE

AMOUNT OF PRESSURE RELIEF NEEDED WHEN ONLY THE SMALLEST ZONE IS OPEN.

NOTE: CONNECT DAMPERS DIRECTLY TO THE PLENUM WHEN POSSIBLE AND BRANCH OFF SMALLER DUCTS GOING TO DIFFERENT AREAS

WITHIN THE ZONES. USING THIS TRUNK/BRANCH DUCT DESIGN WILL MINIMIZE COST AND REDUCE AIR NOISE.

DESIGN & PRE-INSTALL

RETURN AIR

PROBLEMS WITH ZONING CAN

OCCUR WHEN THE RETURN AIR

REGISTERS OR DUCT ARE

UNDERSIZED. INSUFFICIENT CFM

WILL PREVENT SATISFYING VELOCITY

REQUIREMENTS WHEN ALL DAMPERS

ARE OPEN. TO ENSURE THE RETURN

AIR IS LARGE ENOUGH, VERIFY THAT

ITS SURFACE AREA IS SUFFICIENT TO

PASS FULL SPEED BLOWER CFM.

ENSURE ALL ZONES HAVE

UNRESTRICTED AIRFLOW PATH

“BACK” TO A RETURN AIR GRILL

EQUIVALENT TO THE ZONE CFM.

ROUND AND RECTANGULAR DAMPERS

SPRING DAMPERS USE A MOTOR TO POWER THE DAMPER BLADE IN ONE

DIRECTION AND A SPRING TO MOVE THE BLADE IN THE OPPOSITE DIRECTION.

WHEN POWER IS APPLIED TO THE DAMPER, THE MOTOR MOVES THE BLADE.

WHEN POWER IS REMOVED, THE SPRING MOVES THE BLADE IN THE OPPOSITE

DIRECTION.

WARNING: SPRING DAMPERS CONSUME MORE ELECTRICITY THAN POWER-OPEN/

POWER-CLOSE DAMPERS. (10 TO 12 VA WHEN POWERED)

POWER DAMPERS POWER OPEN /POWER CLOSE DAMPERS USE THREE WIRES

TO POWER THE DAMPER OPEN OR POWER IT CLOSED. THE ZONE PANEL IS

RESPONSIBLE FOR SUPPLYING A 24VAC SIGNAL TO EITHER THE PO (POWER

OPEN) OR PC (POWER CLOSED) TERMINAL OF THESE DAMPERS. PRIMARY

ADVANTAGES OF POWER OPEN/POWER CLOSE DAMPERS INCLUDE LOWER

POWER CONSUMPTION, QUIET

OPERATION AND GREATER RELIABILITY. (2.5 TO 3VA)

4

Loading...

Loading...