16

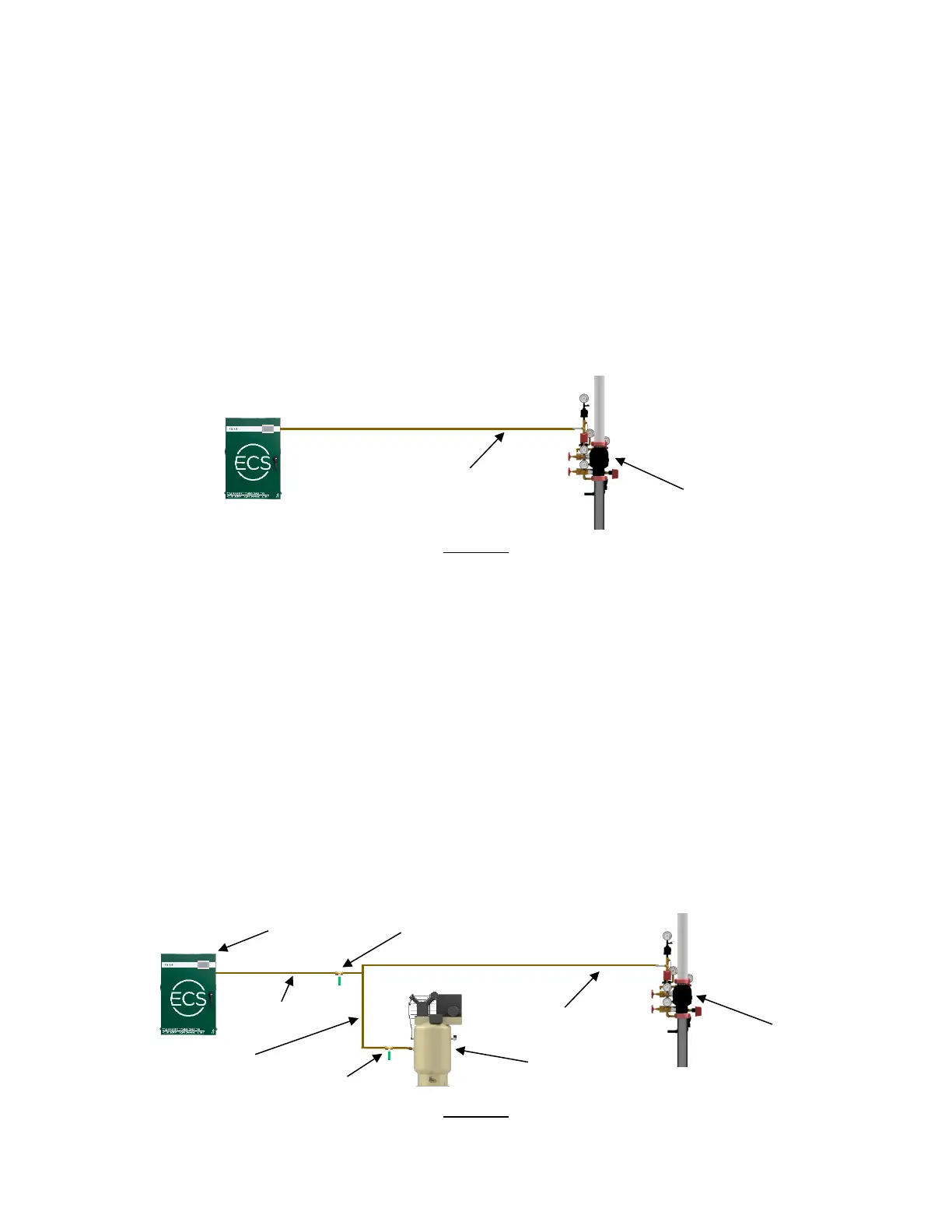

Step 3a: Plumb the Nitrogen/Air Supply Line – No Additional Air Compressor (Figure 3a)

The nitrogen/air discharge plumbing from the Nitrogen Generator must be connected directly to the dry

pipe or preaction valve trim using a minimum ½” black steel, galvanized steel, or copper lines. The size of

the nitrogen/air supply line must be based on both the length of pipe between the nitrogen generator

and fire sprinkler systems and the total volume of fire sprinkler systems being supplied.

NOTES: The Nitrogen Generator requires an in-line Air Maintenance Device (AMD) that is equipped with

an on-board field adjustable pressure regulator for each sprinkler system being served.

Acceptable AMD models are the Reliable Model A, Tyco Model AMD-1 and Victaulic Series 757.

When AG-675 or AG-950 nitrogen generator is connected to a single dry pipe or preaction system,

the nitrogen generator can be installed without an AMD. ECS recommends a ball valve and a check

valve be installed in the nitrogen/air supply line.

Figure 3a

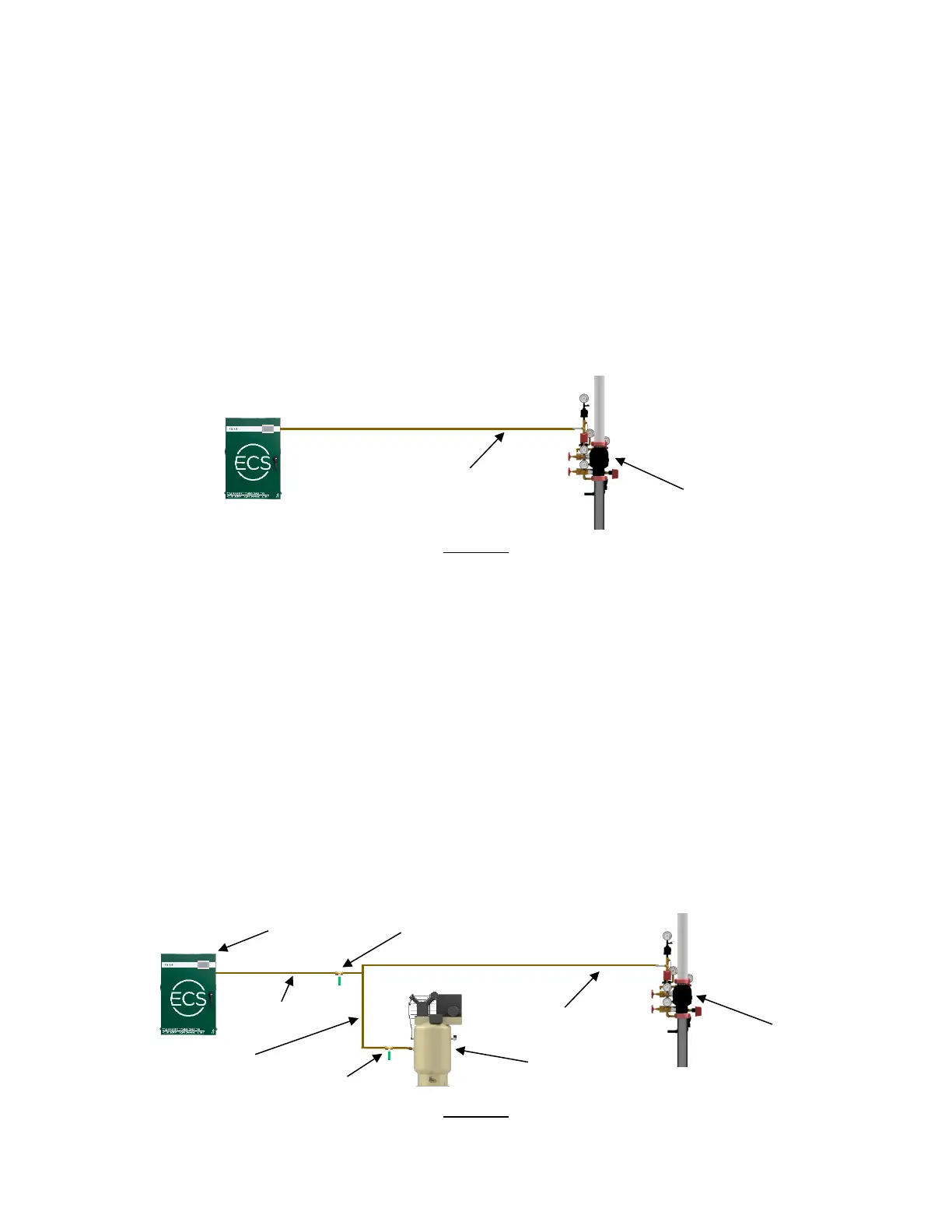

Step 3b: Plumb the Nitrogen/Air Supply Line – With Separate Air Compressor (Figure 3b)

A separate air compressor can be used to meet the NFPA 13 30-minute fill requirement or as a back up to

the nitrogen generator. In this application, the nitrogen/air discharge plumbing from the Nitrogen

Generator and the separate air compressor are connected to the dry pipe or preaction valve trim with

isolation valves in each supply line using a minimum ½” black steel, galvanized steel, or copper lines. The

size of the nitrogen/air supply line must be based on both the length of pipe between the nitrogen

generator and fire sprinkler systems and the total volume of fire sprinkler systems being supplied.

NOTES: The Nitrogen Generator requires an in-line Air Maintenance Device (AMD) that is equipped with

an on-board field adjustable pressure regulator for each sprinkler system being served.

Acceptable AMD models are the Reliable Model A, Tyco Model AMD-1 and Victaulic Series 757.

When AG-675 or AG-950 nitrogen generator is connected to a single dry pipe or preaction system,

the nitrogen generator can be installed without an AMD. ECS recommends a ball valve and a check

valve be installed in the nitrogen/air supply line.

Figure 3b

Loading...

Loading...