59

Handheld Gas Analyzer - Factors Influencing Accurate Readings

1. Elevation changes will affect the accuracy of the nitrogen purity readings. The deviation of the

nitrogen purity can be approximately 1% per 250 feet of elevation.

a. Calibration of the instrument should be performed when elevation at which the product

used changes more than 500 feet.

2. Temperature effects the accuracy of the nitrogen purity readings. The gas analyzer will hold

calibration and correctly read nitrogen purity ±3% when thermal equilibrium within the operating

temperature range. The device must be thermally stable when calibrated and allowed to

thermally stabilize after experiencing temperature changes before readings are accurate.

a. For best results, perform the calibration procedure at a temperature close to the

temperature where analysis will occur.

b. Allow adequate time for the sensor to equilibrate to a new ambient temperature.

CAUTION: “CAL Err St” may result from a sensor that has not reached thermal equilibrium.

Nitrogen Production Flow Rate Check Procedure

The production rate of the nitrogen generator can be verified using the production flow meter in the

nitrogen generator cabinet (See Generator Configuration Diagram).

1. With the nitrogen generator powered and in the nitrogen production mode:

a. Open the nitrogen production flow meter isolation ball valve to automatically start the

nitrogen generator.

b. Close the regulated and fast fill valves on the air maintenance device (AMD) to the fire

sprinkler system(s).

c. Read and document the nitrogen production flow rate on the nitrogen production flow meter.

i. Flow rate indicated is in standard cubic feet per hour (SCFH).

ii. The production rate is measured using the center of the silver ball in the flow meter.

d. Open the regulated valve on the air maintenance device (AMD) to the fire sprinkler system(s).

e. Close the flow meter isolation ball valve.

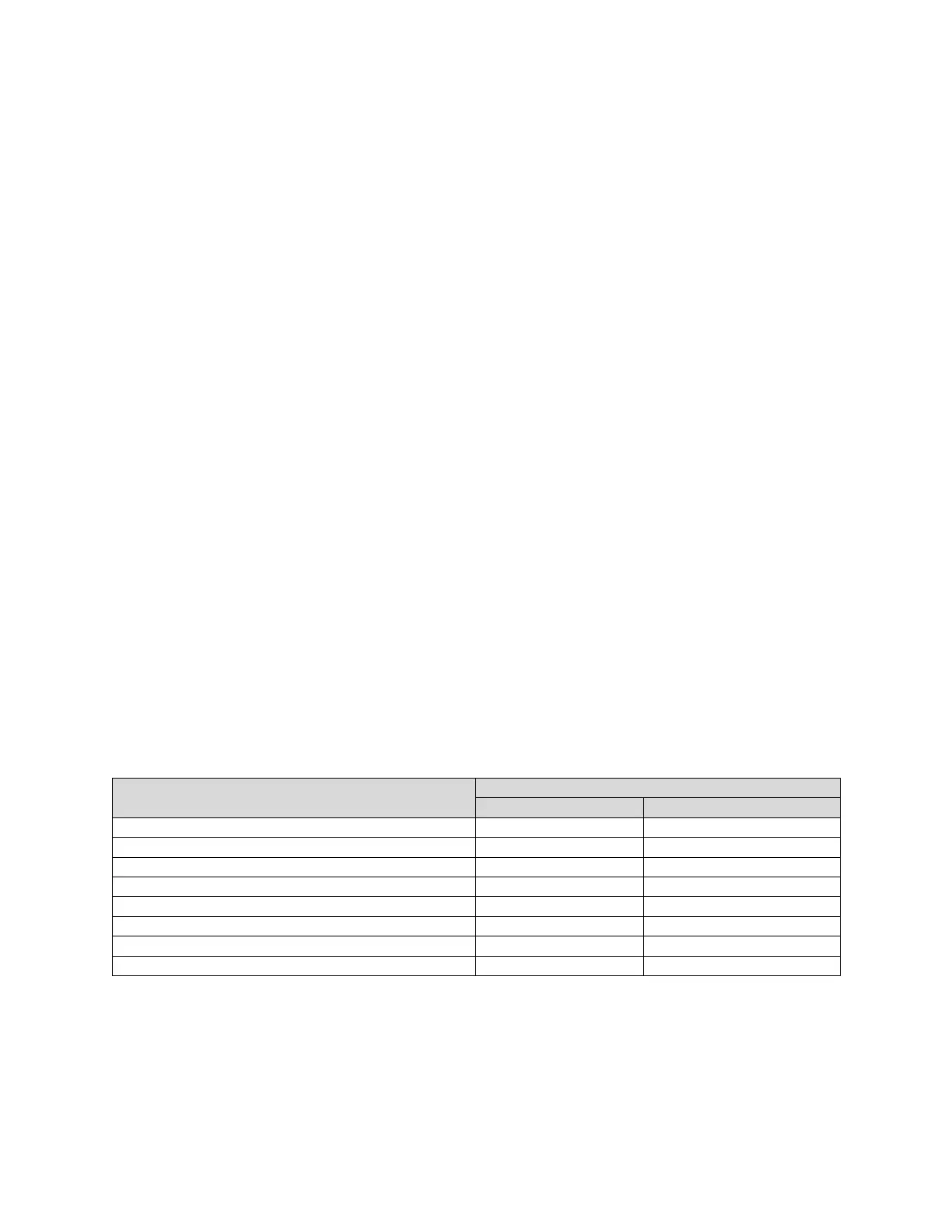

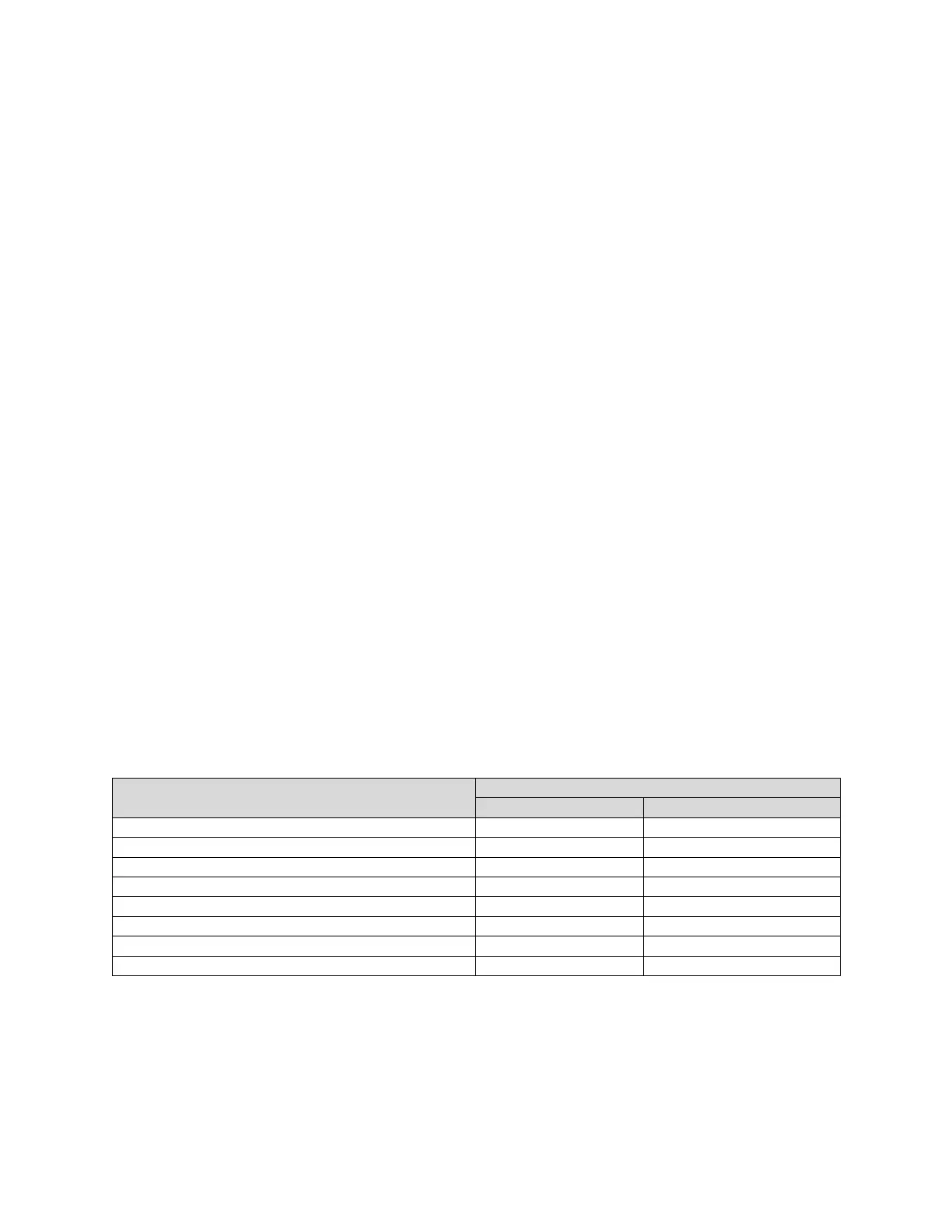

f. Compare the nitrogen production flow rate with the nitrogen production values listed in the

following chart.

Nitrogen Generator Flow Rates

NOTE: If production flow rate is lower than flow rates in the production chart, check pressure regulator

of the excess bleed off assembly.

If production flow rate identified and documented varies more than 10% of the flow rates in the

production chart, Contact ECS.

Loading...

Loading...