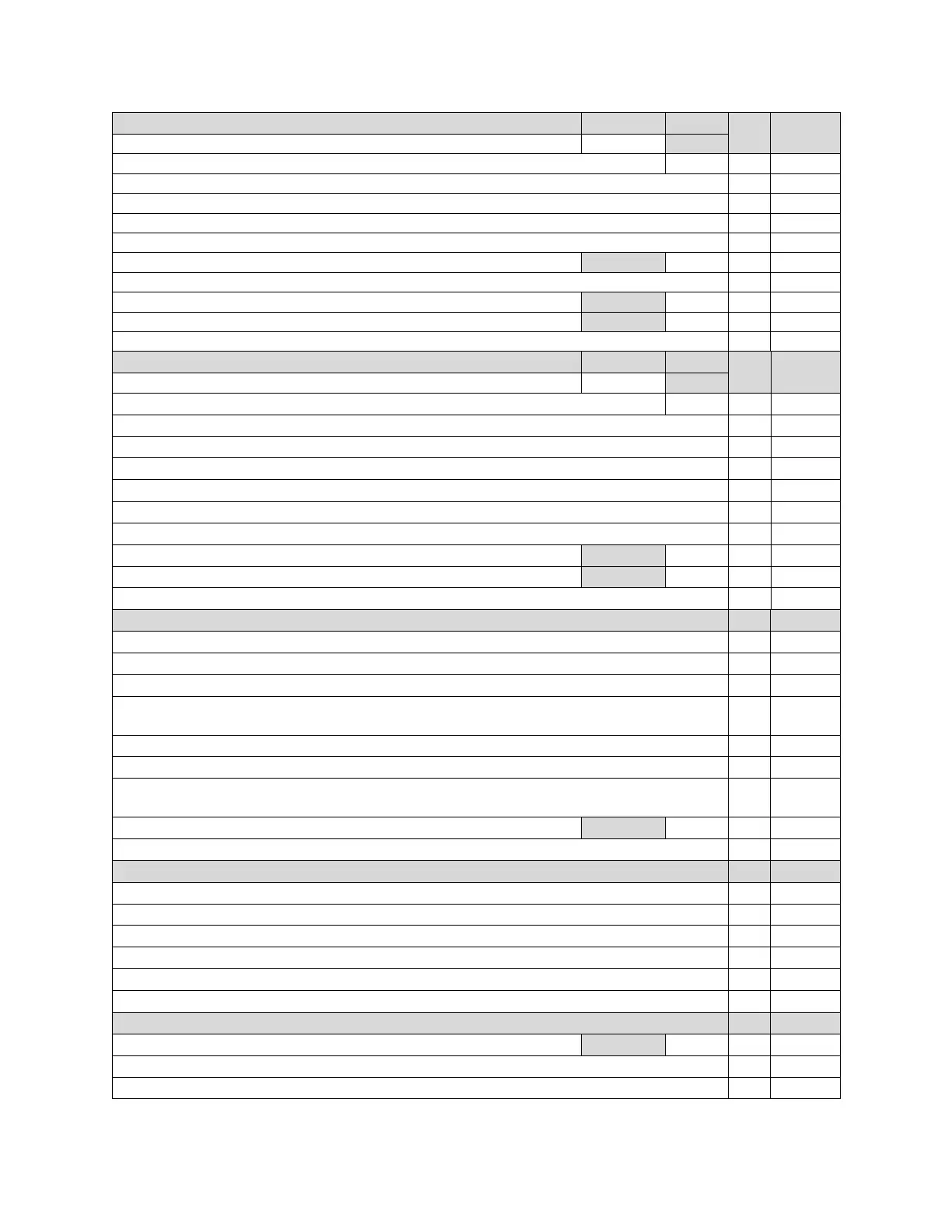

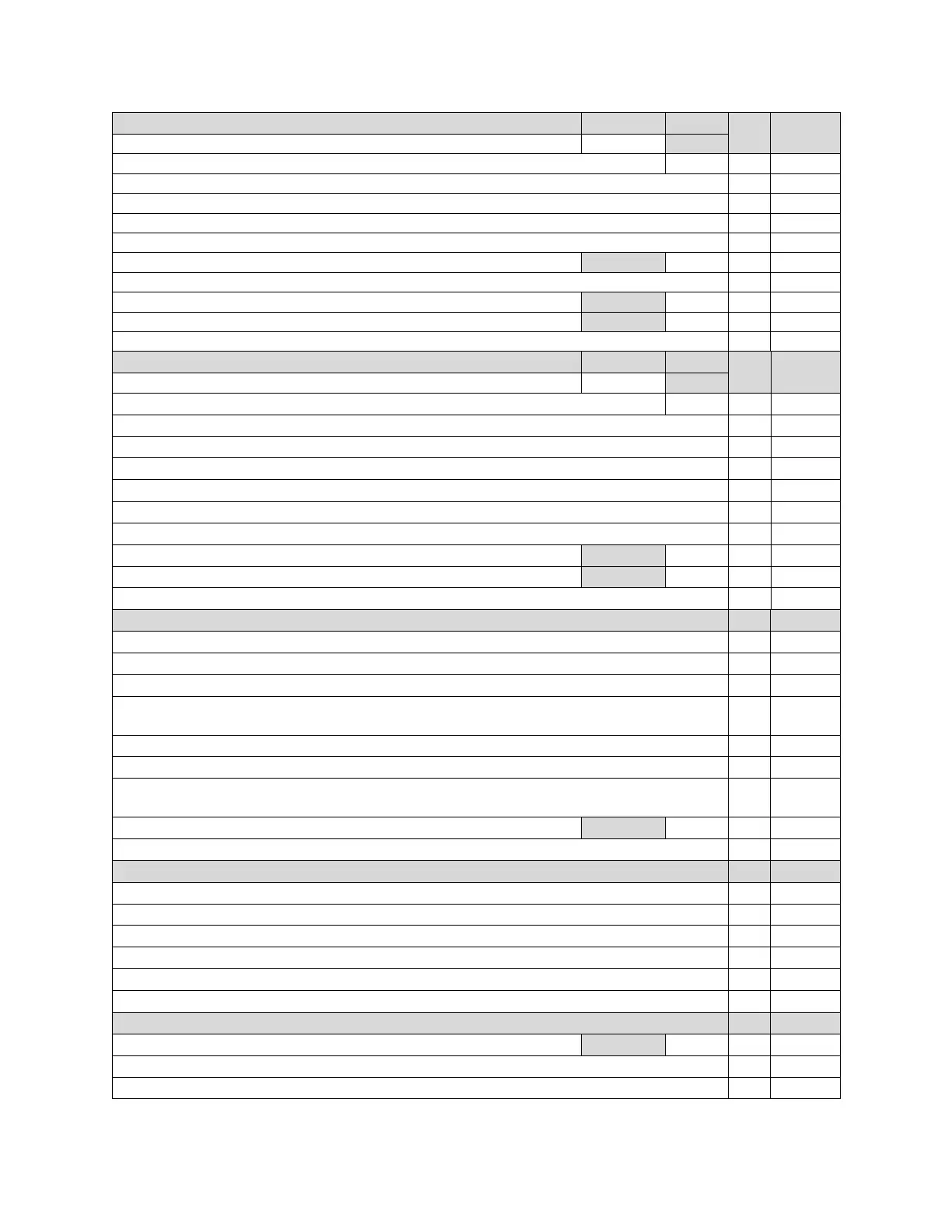

Nitrogen Generator – Quarterly Maintenance

Verify run time (hours) on nitrogen generator – Hour Meter

Verify cycle count on nitrogen generator – Cycle Counter

Verify nitrogen generator is turning on/off at low/high pressure

Verify pressure gauges are in working order (replace as necessary)

Verify all manual valves fully open and close (repair/replace as necessary)

Verify all manual valves operate smooth-clean and un-corroded (repair/replace as necessary)

Check coalescing filter gauge(s) (replace filters as necessary)

Check electrical connections in cabinet, control box and pressure switch (repair as necessary)

Verify correct nitrogen purity level out of cabinet sampling port

Verify nitrogen production level through cabinet flow meter

Check nitrogen generator and supply piping for leaks (repair as necessary)

Nitrogen Generator – Annual Maintenance

Verify run time (hours) on nitrogen generator – Hour Meter

Verify cycle count on nitrogen generator – Cycle Counter

Verify nitrogen generator is turning on/off at low/high pressure

Verify pressure gauges are in working order (replace as necessary)

Verify all manual valves fully open and close (repair/replace as necessary)

Verify all manual valves operate smooth-clean and un-corroded (repair/replace as necessary)

Replace coalescing filters

Check electrical connections in cabinet, control box and pressure switch (repair as necessary)

Verify correct nitrogen purity level out of cabinet sampling port

Verify nitrogen production level through cabinet flow meter

Check nitrogen generator and supply piping for leaks (repair as necessary)

Oxygen Removal Vents – Annual Maintenance

Inspect Y-Strainer for dirt and debris (clean as necessary)

Insect vent filter dirt and debris (clean/replace as necessary)

Verify pressure regulator and gauges are in working order (replace as necessary)

Verify the pressure regulator closes at the determined set pressure (repair/replace as

necessary

Verify all manual valves fully open and close (repair/replace as necessary)

Verify all manual valves operate smooth-clean and un-corroded (repair/replace as necessary)

Check electrical connections in control cabinet and solenoid (SMART Vent) (repair as

necessary)

Verify correct nitrogen purity level out of vent sampling port

Check vent and piping for leaks (repair as necessary)

Corrosion Monitoring – Quarterly Maintenance

Verify corrosion detector has not activated (replace probe/detector as necessary)

Verify remote test station batteries operational (replace as necessary)

Verify all manual valves fully open and close (repair/replace as necessary)

Verify all manual valves operate smooth-clean and un-corroded (repair/replace as necessary)

Check electrical connections on corrosion detector pressure switch and monitoring equipment

Check device and piping for leaks (repair as necessary)

Permanent Gas Analyzer – Quarterly Maintenance

Verify correct nitrogen purity level displayed on Gas Analyzer

Check electrical connections in control cabinet (repair as necessary)

Check nitrogen sampling tubing for leaks (repair as necessary)

Loading...

Loading...