79

INSPECTION, TESTING and MAINTENANCE REPORT

Only qualified personnel can perform inspection, testing and maintenance of the nitrogen generation

equipment. Prior to any system maintenance on the nitrogen generation system, ensure that the nitrogen

generator is isolated from the compressed air supply and all system risers. Ensure that the nitrogen

generation system and the associated piping that is to be manipulated is completely depressurized prior

to performing any maintenance. Failure to do so can result in system damage and/or personal injury.

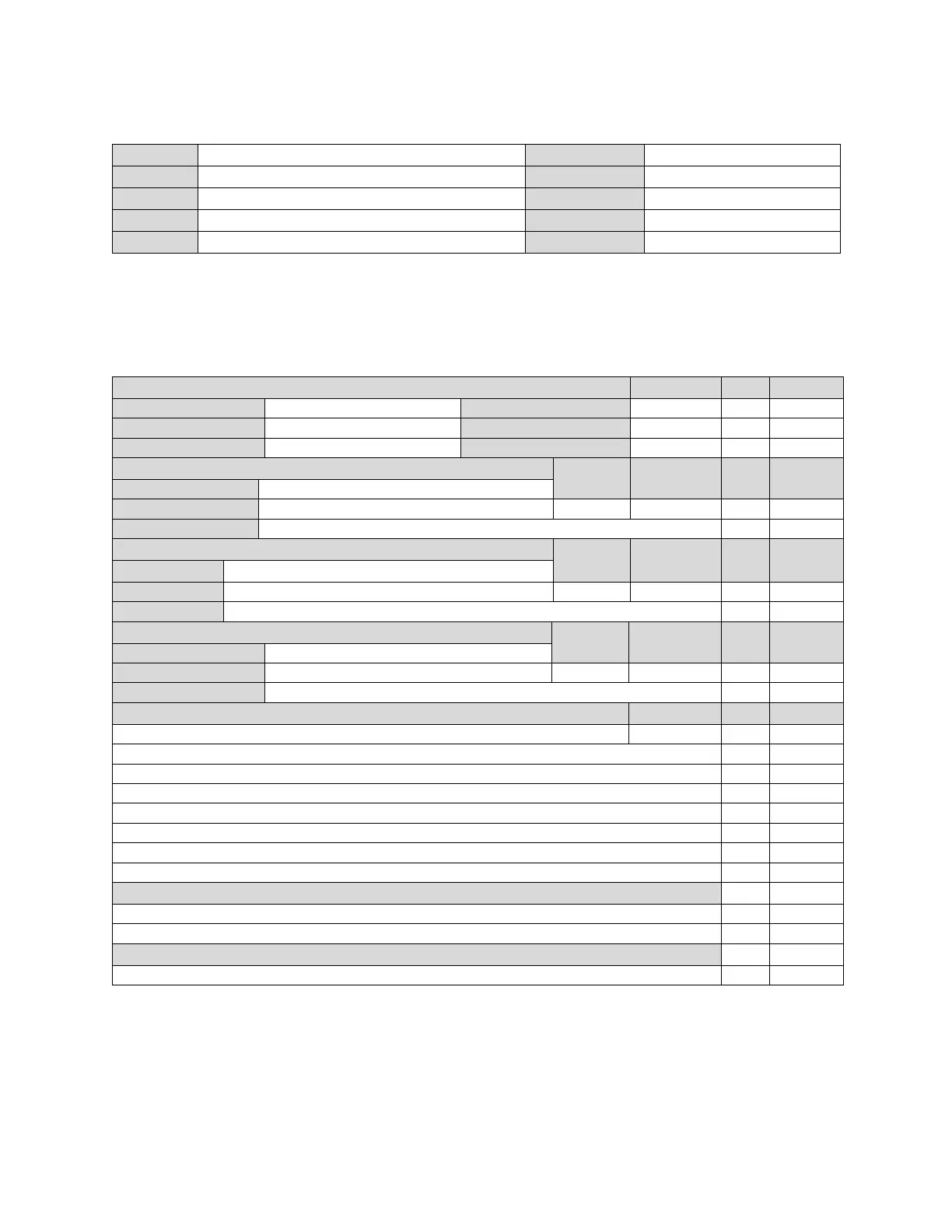

Sprinkler System Information

Nitrogen Generator Air Compressor Information

Existing/Backup Air Compressor Information

Nitrogen Generator Information

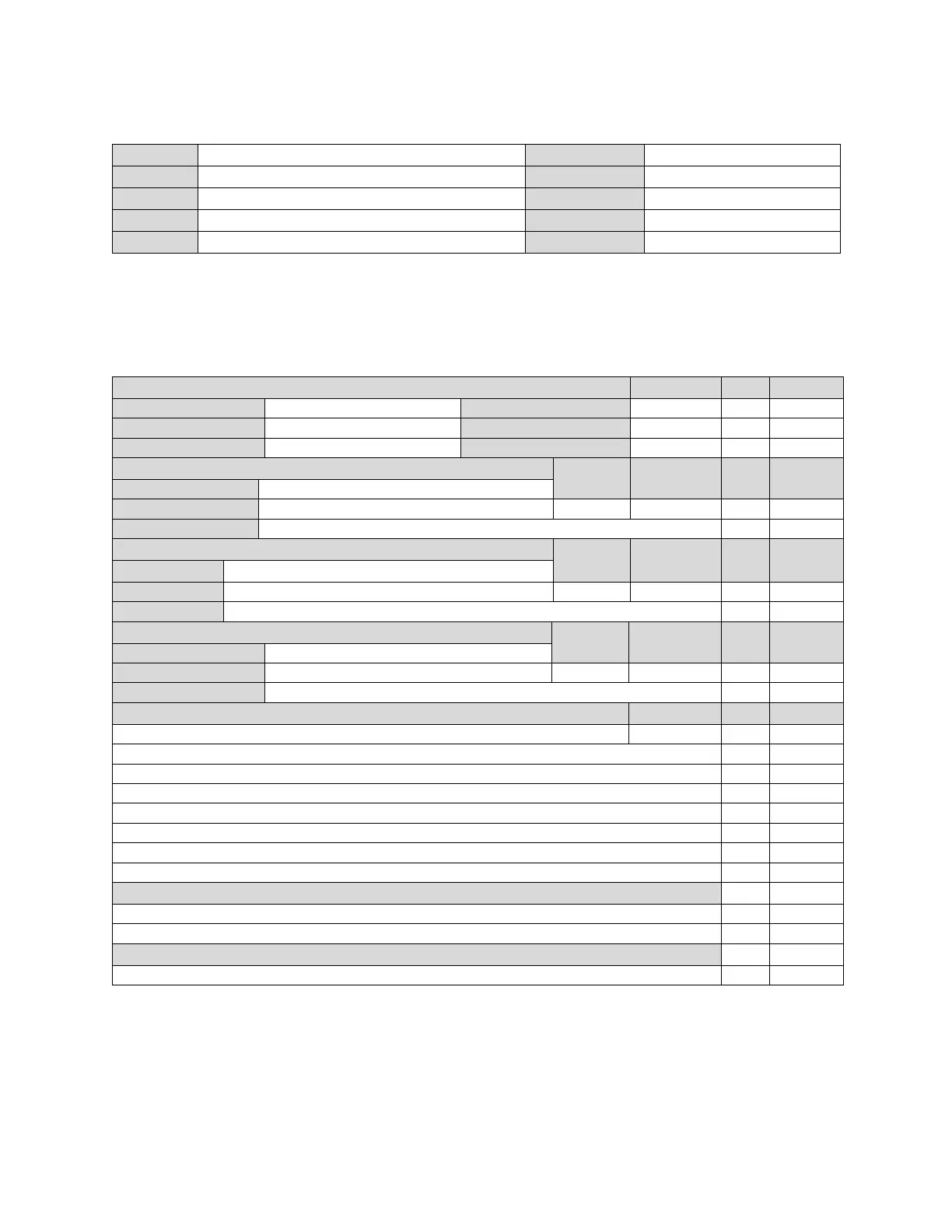

Air Compressor – Quarterly Maintenance

Verify run time (hours) on air compressor (use nitrogen generator hour meter)

Verify compressor is turning on/off at low/high pressure

Verify pressure gauges are in working order (replace as necessary)

Verify all manual valves fully open and close (repair/replace as necessary)

Verify all manual valves operate smooth-clean and un-corroded (repair/replace as necessary)

Check air compressor filter(s) (clean or replace as necessary)

Check electrical connections in control box and pressure switch (repair as necessary)

Check air compressor and supply piping for leaks (repair as necessary)

Air Compressor – Splash Lubricated

Check drive belt and drive belt tension (repair/replace as necessary)

Replace crankcase oil (3 months or 500 hours whichever comes first)

Air Compressor – Oil-Less

Rebuild compressor cylinders (5,000 hours)

Loading...

Loading...