Printed in USA

TVW ©2003

Page 13

E-2EC-2GC-411-I-1003

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com • Email: sales@edcoinc.com

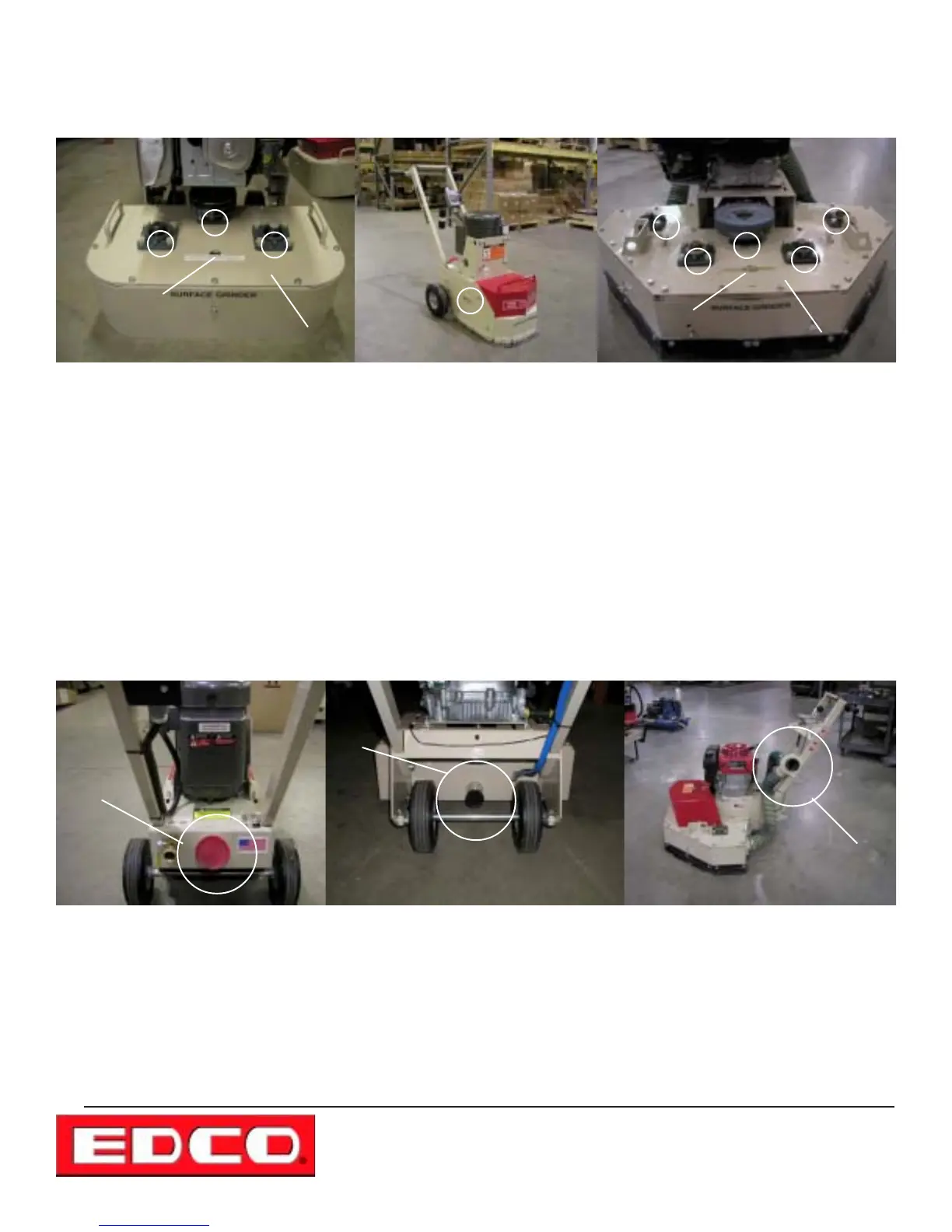

PROCEDURE FOR LUBRICATING FLANGE BEARINGS

To grease the flange bearings attach the grease gun to the grease fittings and give only two (2) pumps on the grease gun

every 50 hours of use. If excessive over lubrication is done grease will leak onto the work surface causing possible damage

and wasted cleanup time.

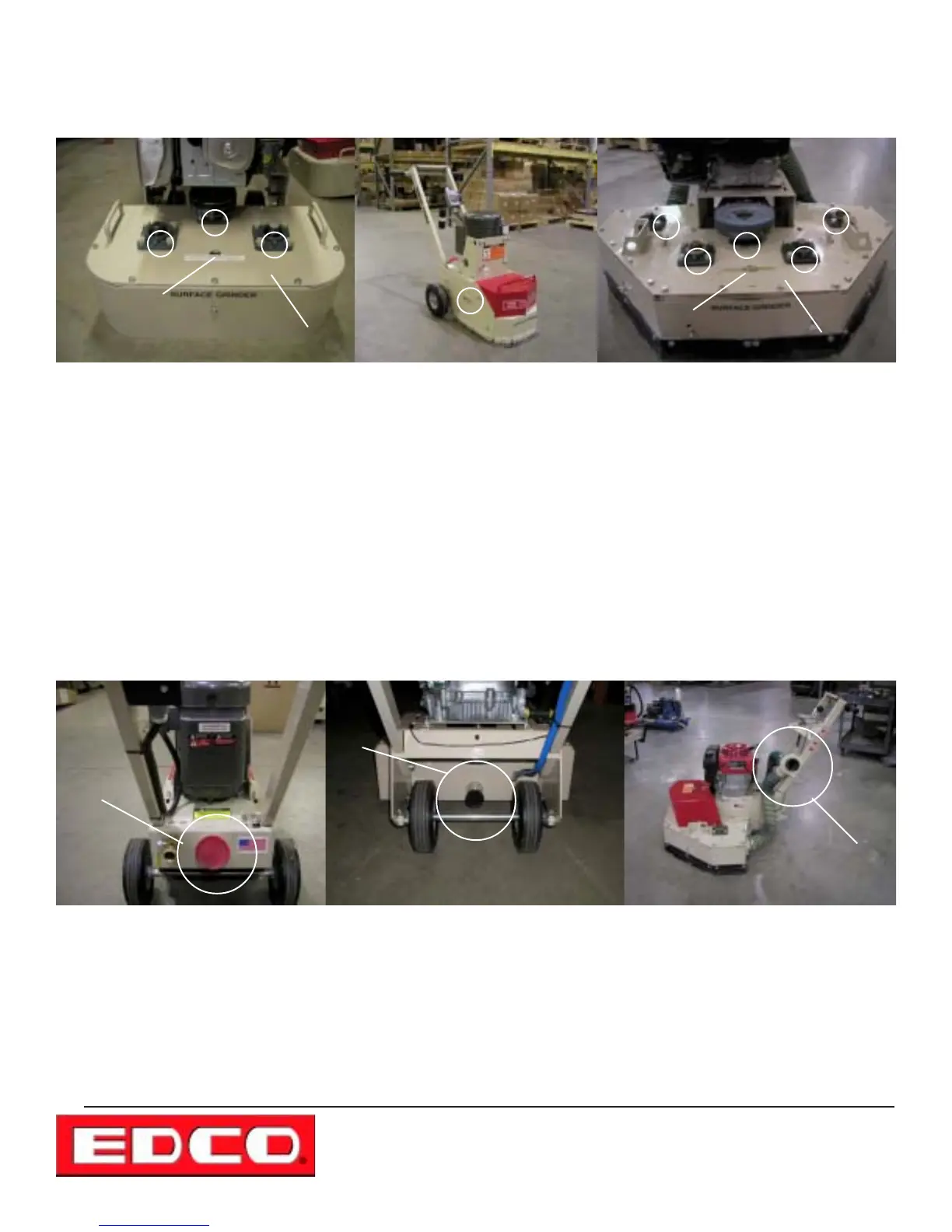

If using a vacuum for dust control attach it to the vacuum port at the rear of the machine except for the 411 which is on the

handle as pictured above, securing it with clamps. The ports are circled in the photos above.

PROCEDURE FOR ATTACHING A VACUUM

The procedure is the same for two or four disc machines. The red hood has to be removed to access the grease points on

theflange bearings. The single disc grinder is lubricated from the fittings on the exterior of the machine. The grease points are

circled in the photos above. There are duplicate grease fittings on the underside of the 2-EC, 2-GC and the 411 models. The

skirts will have to be removed to access the grease points.

S-EC

2-GC

411

Inspection

hole

Inspection

hole

Gear

case

Gear

case

Vac

Port

Vac

Port

Vac

Port

Loading...

Loading...