Stand / Version

01 / 2020

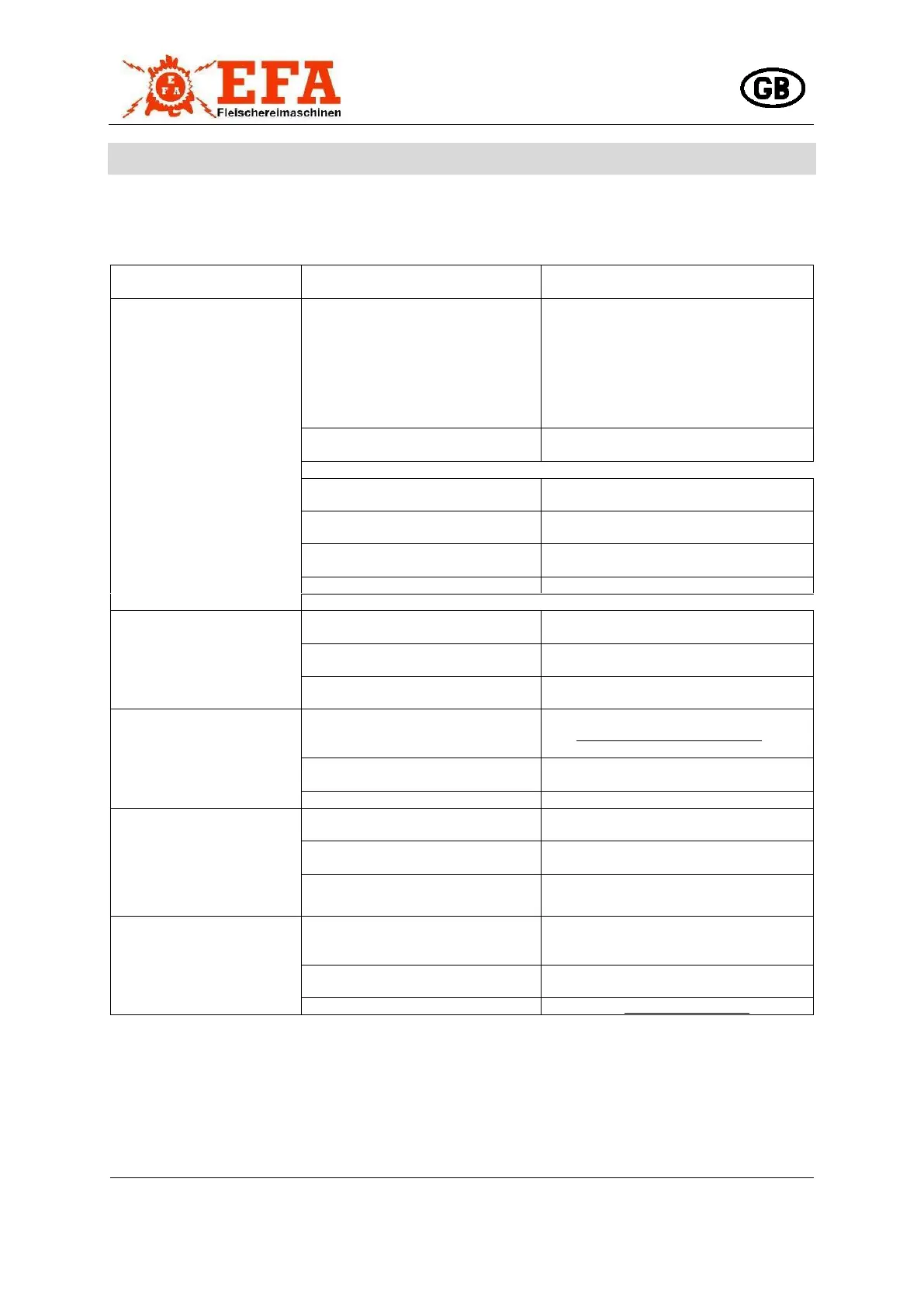

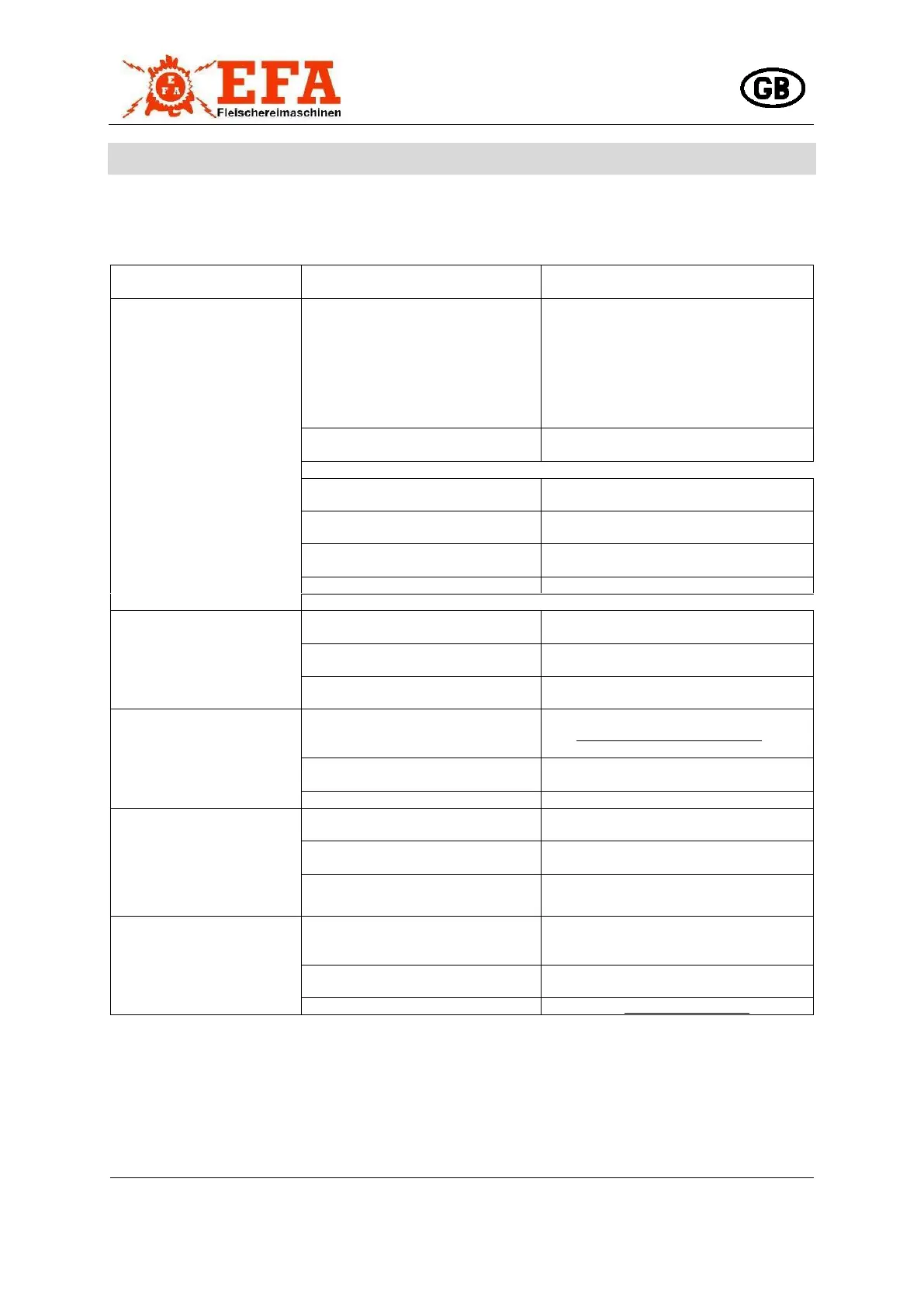

6 Maintenance

Malfunctions may occur during operation, but these are generally relatively simple to remedy. Table 1:

"Faults and corrective measures" describes these malfunctions together with their possible causes

and suggests corrective measures

Saw won't start when press-

ing the switches (checking

the saw)

Broken wire in connection cable

Check electric conductivity of controller's

terminal connections (no power sup-

plied!):

a) Terminals UVW or 1, 2, 3 (check mo-

tor connection)

b) Terminals No.: 3 - 4 (2. Handle)

c) Terminals No.: 5 - 6 (Motor switch and

lid guard)

Both switches not uniformly

pressed within less than 0.3 s

Press both switches again within 0.3 s

Front/rear lids not closed properly

or not firmly attached

Check and firmly close lids until contact

is made

Check electr. function, replace if neces-

sary

Connecting line not terminated

properly

Check, re-tighten/re-attach terminals

Check motor, replace if necessary

Saw won't start when press-

ing the switches (checking

the controller)

Wires not properly attached to ter-

minals

Check terminals and remove fault

Power contactor (labelled K1/K1M)

defective

Check and replace power contactor as

necessary

2-hand safety block (labelled KO)

defective

Check and replace 2-hand safety block

as necessary

Saw starts when switches

are pressed but stops under

applied load

Wire cross-section too small and/or

cable too long

Check dimensions according to the an-

nex 13.4 "Cross-sections of wires" and

change if necessary

Check and remove voltage drop (S&W

provide the relevant test equipment)

Use torque wrench to tighten belt

Saw won't always start

when pressing the switches

or intermittently starts/stops

2-hand safety block (labelled KO)

defective

Check and replace 2-hand safety block

as necessary

Power contactor (labelled K1/K1M)

defective

Check and replace power contactor as

necessary

Wires not properly attached to ter-

minals

Check terminals and remove fault

Guide plate of front guide pulley too

tight or jammed

Check for smooth operation, use torque

wrench to loosen or re-grease as neces-

sary

Check using torque wrench (torque too

great)

see section 5.2 "Saw belt guide"

Loading...

Loading...