2

circulator may be located on the return line

as shown in the diagram or in the supply

p

iping if desired. The aquastat is wired at the

factory. For power and thermostat wiring see

Figures 2, 3 and 4 in this manual and the

wiring diagrams in the thermostat manufac-

turer’s manual. For piping and wiring of other

system components, see the manufacturer’s

installation manuals. An Expansion Tank (not

provided) must be matched to the system

and installed in accordance with the manu-

facturer’s recommendations. See the manu-

facturer’s instructions for sizing the expan-

sion tank. Do not under-size the expansion

tank. A bypass loop may be installed to

improve tankless coil performance. See

Figure. 7.

3) The tankless water heater may be piped as

shown in Figure 6. A mixing valve, not sup-

plied, must be used to reduce the water

temperature at kitchen or bathroom taps.

High temperature water for a dishwasher

may be obtained by piping as shown in

Figure 6. The nuts that secure the tankless

coil flange should be tightened before the

boiler is filled with water, after initial firing and

once a year during the annual maintenance.

DETERIORATION DUE TO COIL GASKET

LEAKS WILL VOID THE WARRANTY.

4) The VT series boilers are equipped with an

air eliminator feature that uses a dip tube

construction on the boiler supply fitting. This

feature allows quiet air free operation of your

hot water system by assuring the removal of

air pockets without the installation of Air

Scoops to trap noisy air.

The 1-1/4" supply line or Riser tapping in the

top of the boiler extends approximately 1"

below the top or waterline of the boiler, thus

allowing only air free water to enter the supply

to the heating system. The air trapped in the

top of the boiler is then purged through a 3/4"

vent tapping to be released with an (1) auto-

matic float vent (2) a manual vent or (3) piped

into a conventional type expansion tank.

Relief valve discharges and drain valve pip-

ing should be piped to a safe place of dis-

charge. All plugs and water connections

should be checked for leaks upon installa-

tion and annually.

5) Be certain the chimney is clean and free of

obstructions. Connect boiler flue outlet to

c

himney using galvanized smoke pipe. The

flue pipe should be pitched upward at least

1/4" per foot of run. Refer to Page 1 in this

manual for proper size flue pipe for your

model boiler. Use only elbows and straight

sections. Tees may be used in a straight sec-

tion in conjunction with a barometric draft

regulator; however, they must not be used

for a 90° turn. Each joint should be securely

fastened with sheet metal screws. The flue

pipe must not be inserted beyond the inside

wall of the chimney. Install barometric draft

regulator in the horizontal or vertical section

of the flue pipe. The chimney should provide

a minimum of .04 draft at the boiler flue out-

let. A draft of .04 is ideal. The draft losses for

VT Series Boilers are listed below.

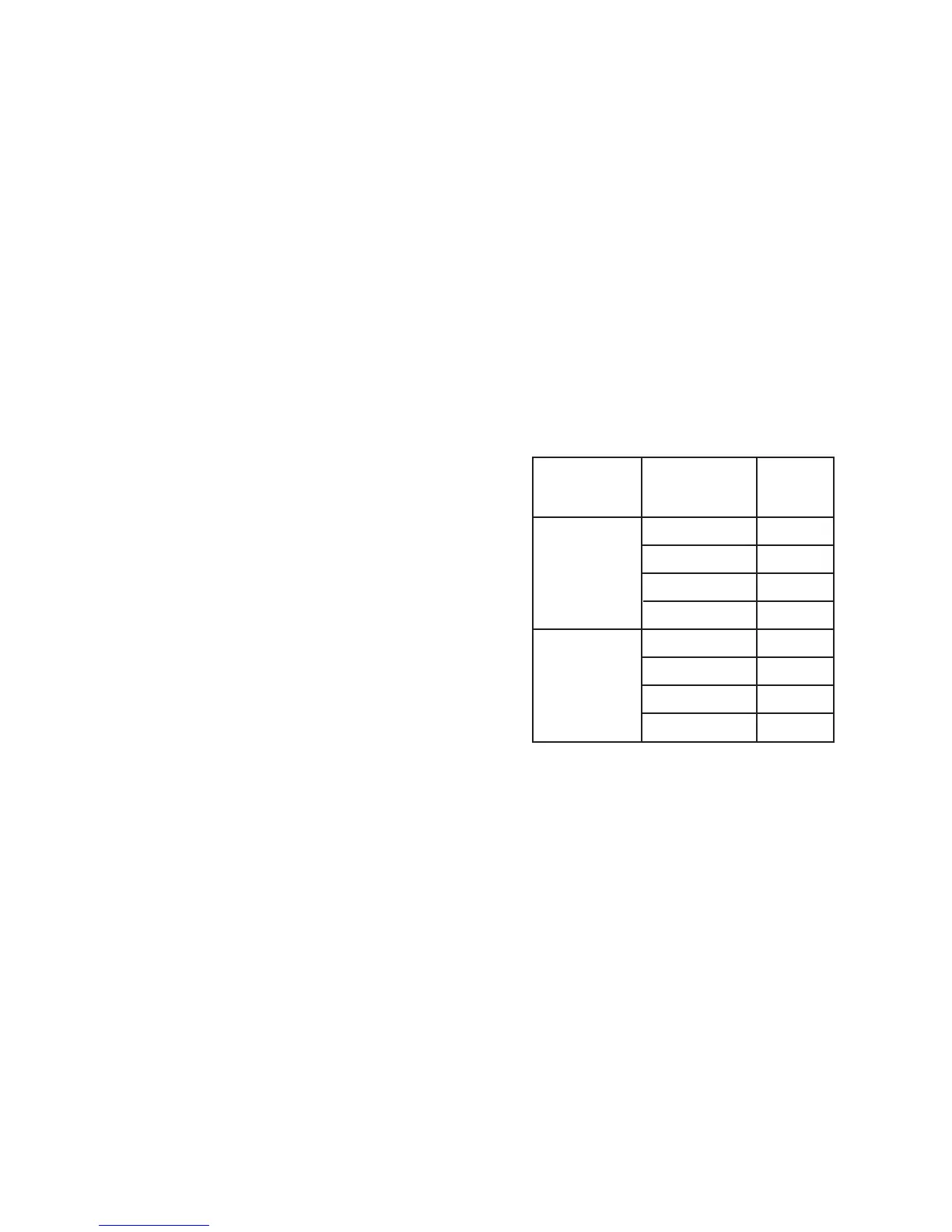

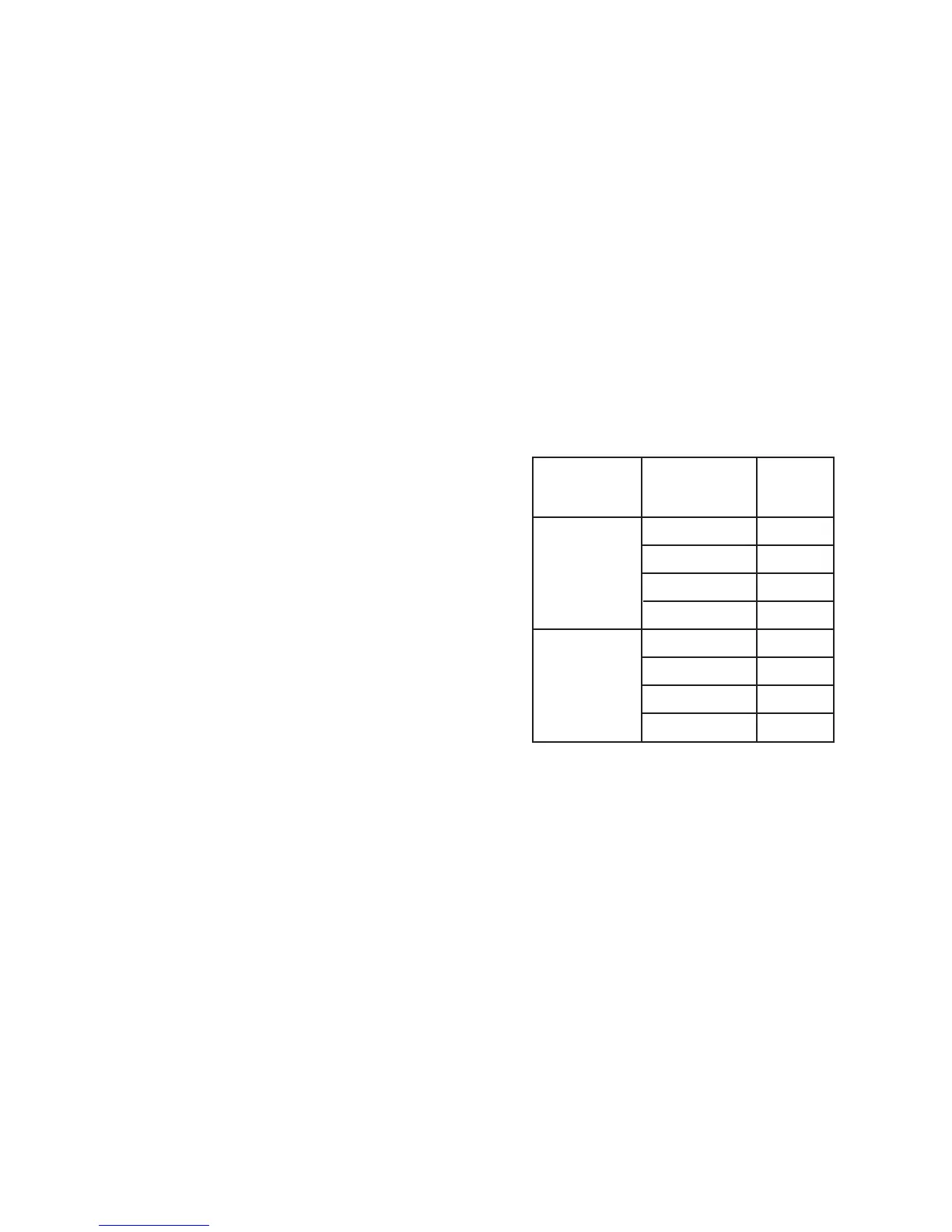

MODEL Firing Draft

Rate Loss

0.65GPH .002

0.75GPH .005

VT700E

0.85GPH .015

1.00GPH .020

1.10GPH .005

1.35GPH .010

VT1000E

1.50GPH .020

1.65GPH .025

6) The boiler room must be well ventilated to

allow sufficient make-up air to support com-

bustion. Lack of adequate combustion air

may result in erratic operation of the burner,

noisy combustion or fuel odors. Remember

your need for outside air will be greatly

increased if you have a vented dryer in the

basement or other venting fans in the home.

Boilers located in confined spaces shall be

provided with two permanent openings, one

near the top and one near the bottom of the

enclosure. Each opening shall have a free

area of not less than one square inch per

1000 BTU per hour input rating of the boiler,

freely communicating with interior areas hav-

ing adequate infiltration from the outside.

7) Fill boiler and system with water. Be sure

entire system has been purged of air and the

desired pressure is obtained.

Loading...

Loading...