20

FF..88 EElleeccttrriiccaall ccoonnnneeccttiioonnss

WWAARRNNIINNGG

Work on the electrical

systems must only be

carried out by a qualified

electrician.

• Connection to the power supply must be carried out in

compliance with the regulations and provisions in force in

the country of use.

• Make sure the machine power supply voltage specified on

the rating plate matches the mains voltage.

• Make sure the system power supply is arranged and able

to take the actual current load and that it is executed in a

workmanlike manner according to the regulations in force

in the country of use.

• The earth wire from the terminal board side must be longer

(max 20 mm) than the phase wires.

• Connect the power cable earth wire to an efficient earth.

The equipment must also be included in an equipotential

system, whose connection is made by means of screw EQ

(see par.

Installation diagram

) indicated by the symbol .

The equipotential wire must have a section of at least 10

mm

2

.

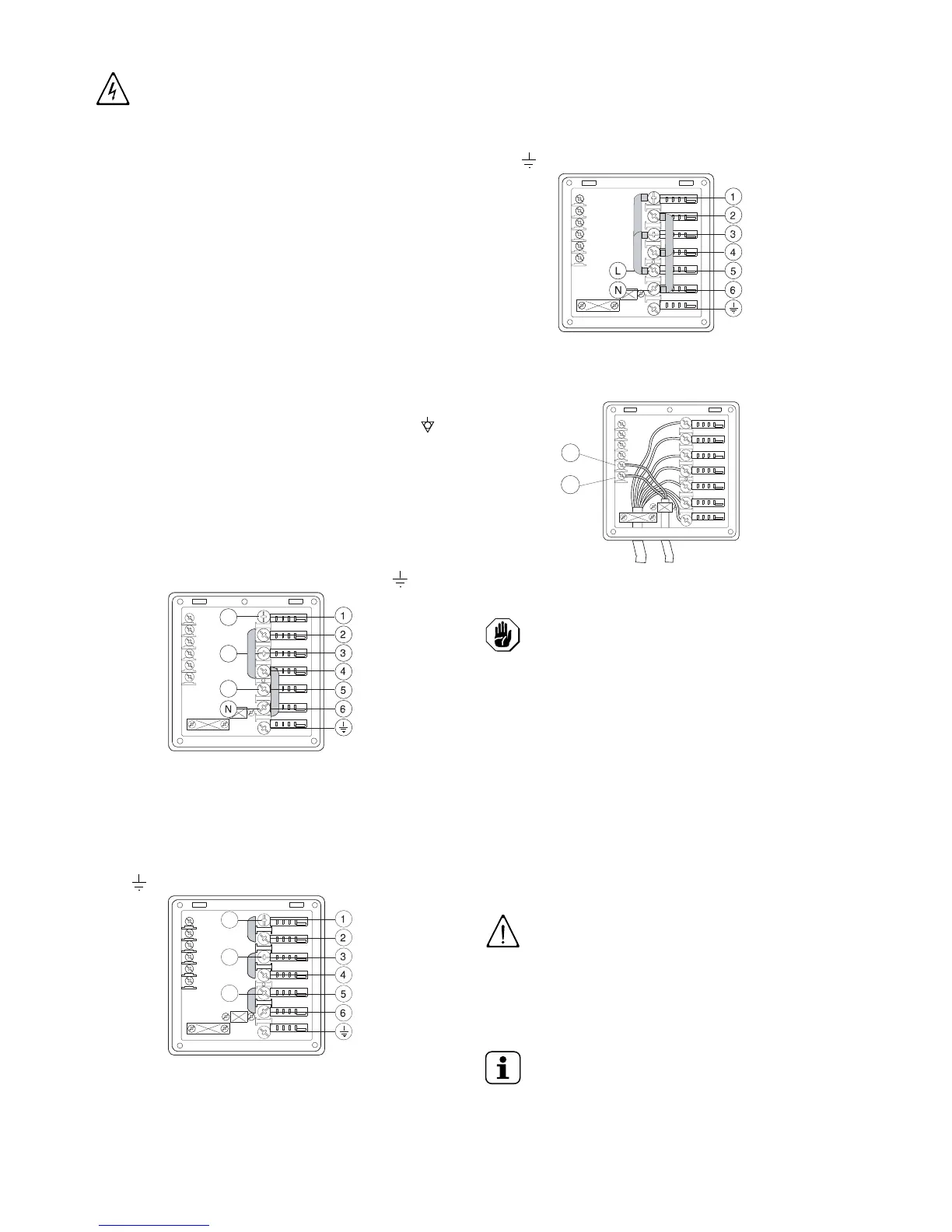

PPoowweerr ssuuppppllyy 440000 -- 441155VV 33NN

Open the power supply terminal board and insert the jumpers

provided as follows: one jumper between terminals 2 and 4

and another between terminals 4 and 6. Using a suitable

power supply cable (see D.1

Main technical characteristics

table), connect the three phases to terminals 1, 3 and 5, the

neutral to terminal 6 and the earth wire to the terminal .

PPoowweerr ssuuppppllyy 222200 -- 223300VV 33

Open the power supply terminal board and insert the jumpers

provided as follows: one jumper between terminals 1 and 2,

one between terminals 3 and 4 and another between

terminals 5 and 6. Using a suitable power supply cable (see

D.1

Main technical characteristics

table) connect the three

phases to terminals 1, 3 and 5 and the earth wire to the

terminal .

PPoowweerr ssuuppppllyy 222200 -- 223300VV 11NN

Open the power supply terminal board and insert the jumpers

provided as follows: two jumpers between terminals 1, 3, 5

and another two between terminals 2, 4 and 6. Using a

suitable power supply cable (see D.1

Main technical

characteristics

table), connect the phase and neutral to

terminals 5 and 6 respectively and the earth wire to the

terminal .

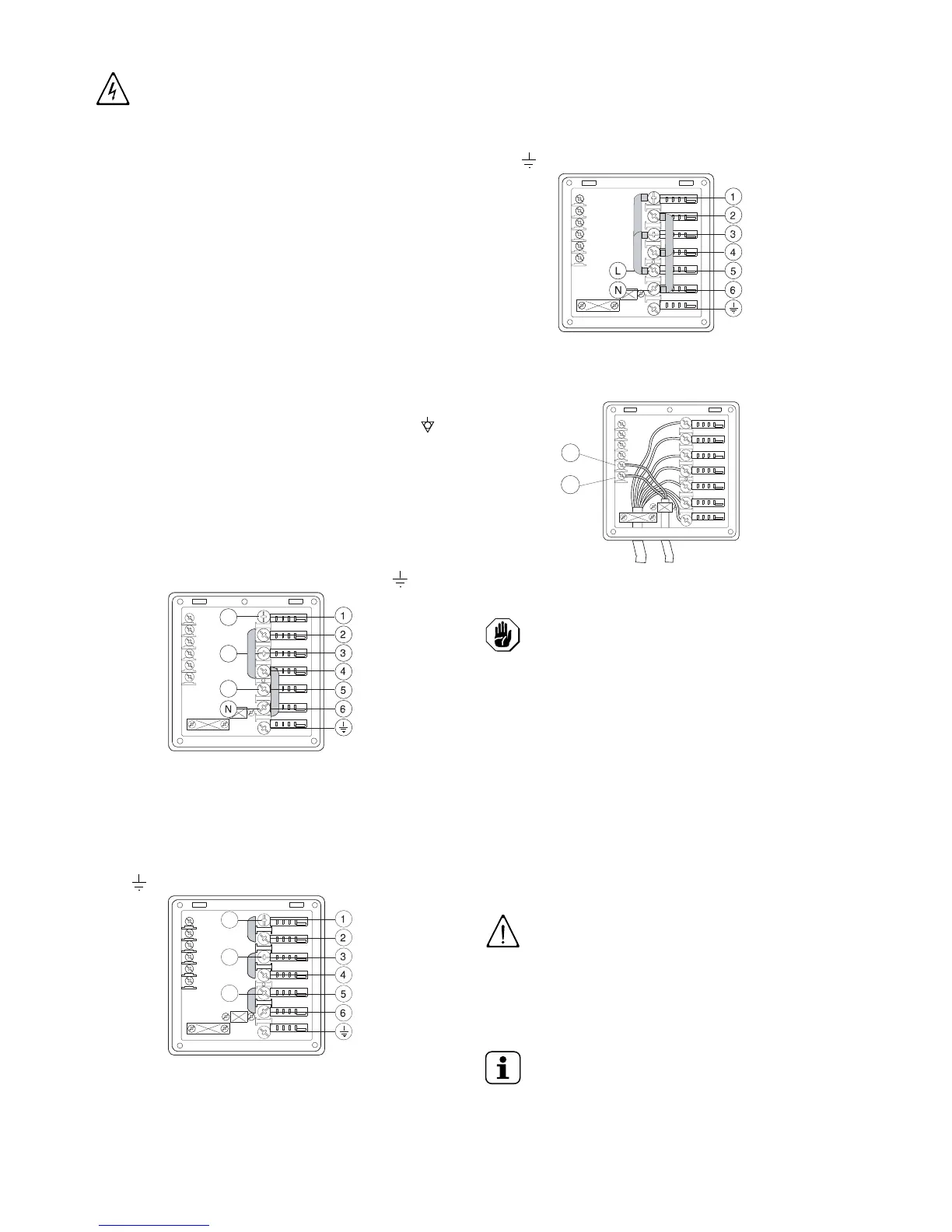

FF..88..11 CCoonnnneeccttiioonnss pprroovviiddeedd ffoorr eenneerrggyy ccoonnttrrooll

This appliance is designed for an external energy

consumption control.

Connect the energy peak controller across terminals 11 and

12.

CCAAUUTTIIOONN

A normally open (n.o.) contact of the

controller must be connected across

terminals 11 and 12. When this contact

closes the boiler heating elements are

disconnected. Using the dishwasher in

these conditions may increase the cycle

time.

FF..99 SSaaffeettyy ddeevviicceess

• An automatic-reset overload protector incorporated in the

electric pump windings cuts off the power to the pump in

case of faulty operation.

• A device prevents the booster water from returning back

into the system in the event of a water supply system fault.

• An overflow pipe connected to the discharge ensures a

constant water level in the tank.

IIMMPPOORRTTAANNTT

The Manufacturer declines any liability if

the accident-prevention regulations are

not respected.

FF..1100 DDeetteerrggeenntt//rriinnssee aaiidd ddiissppeennsseerrss aanndd

pprreeaarrrraannggeemmeennttss

NOTE!

If the machine is connected to a water softener

and/or a reverse osmosis system, contact the

detergent supplier for a specific product.

Loading...

Loading...