EDR and ETR Valves

Instruction Manual

Form 5050

August 2006

5

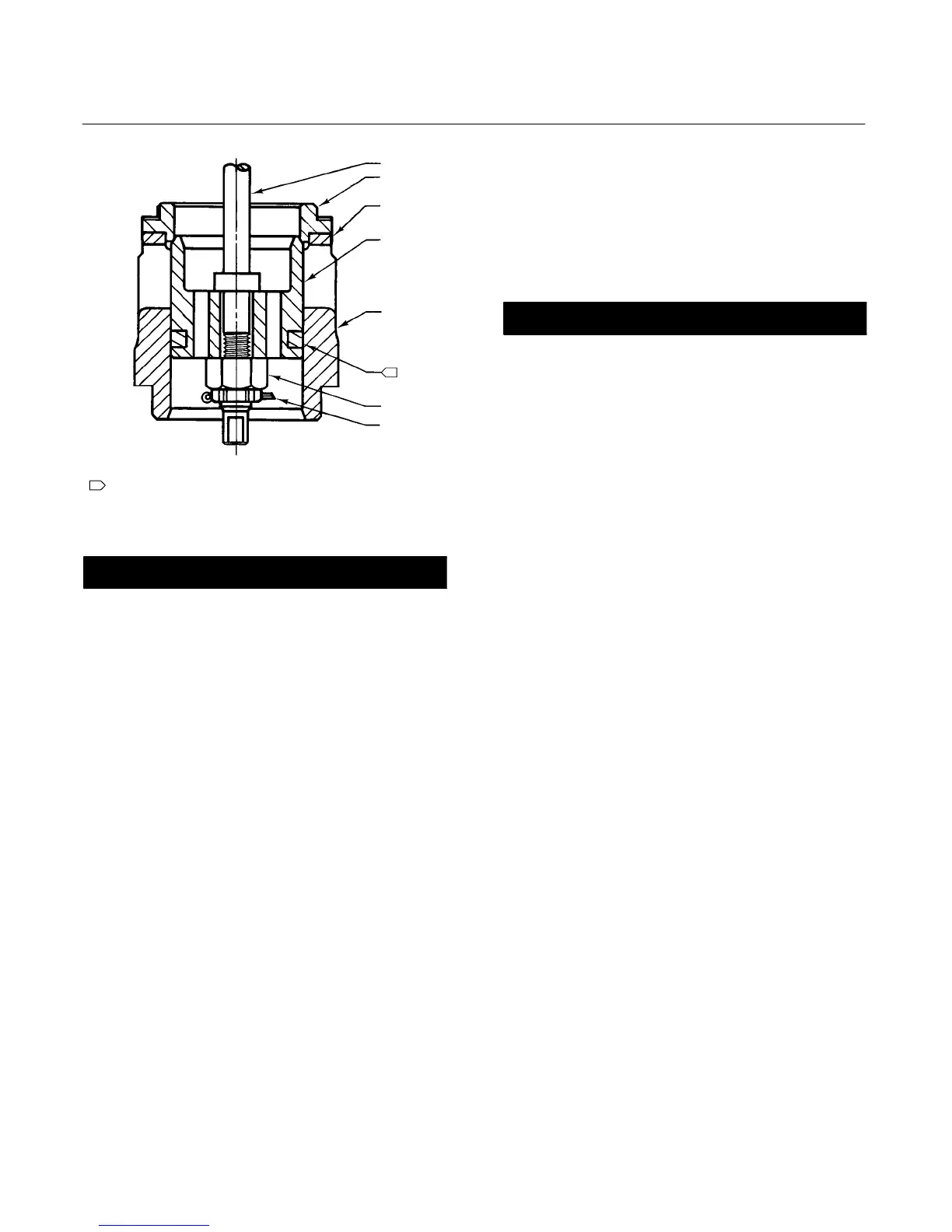

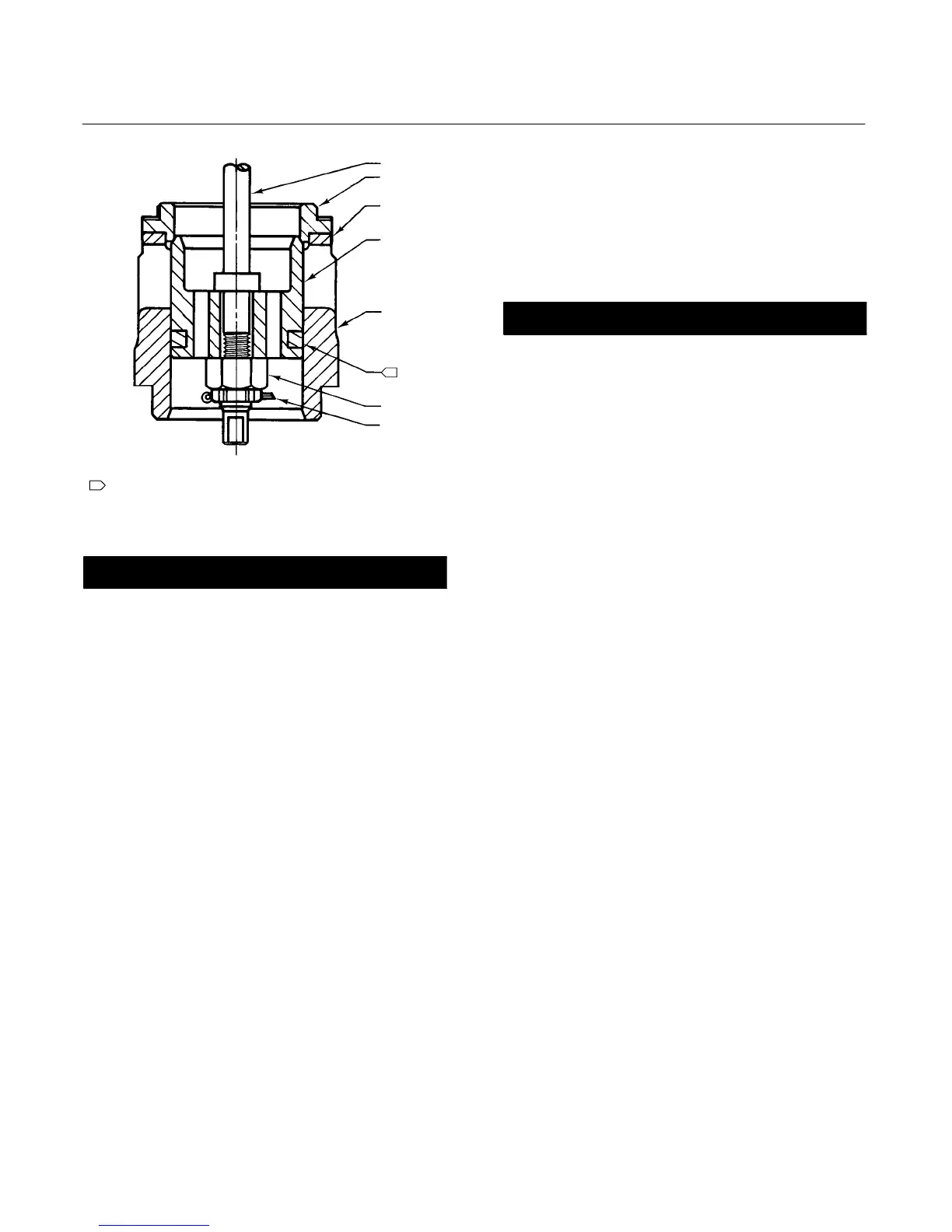

STEM

DISK SEAT

DISK

VALVE PLUG

CAGE

CASTLE NUT

COTTER PIN

DESIGN ETR OR EDR

NOTE:

DESIGN ETR USES A SEAL RING (KEY 24) AND A BACKUP RING

(KEY 25) (SEE FIGURE 12).

40A5479-B

B2360 / IL

1

1

Figure 3. Valve Plug Assembly

CAUTION

Take care when removing the bottom

flange (key 31) in the following

procedure, to prevent possible product

damage from parts unexpectedly

falling out of the valve body.

1. Isolate the control valve from the line pressure,

release pressure from both sides of the valve body,

and drain the process media from both sides of the

valve. If using a power actuator, also shut off all

pressure lines to the power actuator, release all

pressure from the actuator. Use lock-out procedures

to be sure that the above measures stay in effect

while you work on the equipment. When removing the

bottom flange (key 31), be careful that the cage and

other parts are not damaged by unexpectedly falling

out of the valve body. Remove the nuts (key 16) or

cap screws from the bottom flange.

2. Removing the valve plug from the valve body, the

valve plug can be removed independently of the

valve stem by removing the cotter pin and castle nut

(keys 30 and 8). Then, slide the valve plug out of the

cage (see figure 3).

D Disconnect the stem connector, and loosen the

packing flange nuts (see figure 2).

D Move the valve stem away from the actuator

stem allowing room to remove the indicator disk and

stem locknuts. Remove the parts indicated.

D Remove the valve plug by pulling the valve

plug/stem assembly through the packing and out of

the bottom of the bonnet.

D If the valve plug is to be re-used but the stem

needs to be replaced, drive the pin (key 8) out of the

plug/stem assembly and unscrew the valve stem.

CAUTION

Take care during disassembly in the

following procedure, to prevent

possible damage to sealing surfaces.

3. Remove the seat ring (key 9), gaskets

(keys 10, 11, 12, and 13), and any remaining parts if

they did not come out with the valve plug. If the seat

ring (key 9) is stuck in the valve body, strike the

outside of the valve body at the seat ring line with a

rubber hammer while pulling down on the seat ring.

Carefully remove the seat ring without damaging

sealing surfaces.

If necessary, machine or grind metal seats before

installing the piston ring/seal ring or packing, or refer

to the Lapping Metal Seats procedure in this section.

Lapping Metal Seats

A certain amount of leakage should be expected

with metal-to-metal seating in any valve body. If the

leakage becomes excessive, however, the condition

of the seating surfaces of the valve plug and seat

ring can be improved by lapping. (Deep nicks should

be machined out rather than ground out.) Use a

good quality lapping compound of a mixture of 280

to 600-grit.

Assemble the valve to the extent that the seat ring

(key 9), cage (key 3), cage adaptor (key 4, if used),

and bonnet are in place. Also, remove the piston ring

or seal ring from the valve plug (if used).

1. Insert the valve stem (key 7) into the bonnet and

thread the plug (key 2) onto the end of the stem.

Make a simple handle from a piece of strap iron; lock

it to the valve with the stem locknuts.

2. Apply the lapping compound to the seating

surfaces. Rotate the handle alternately in each

direction to lap the seats. After lapping the seats,

remove the valve plug and stem, then clean all parts.

Repeat the lapping procedure if necessary.

Trim Assembly

Carefully clean all gasket surfaces. Use new gaskets

during reassembly of the valve.

Loading...

Loading...