EDR and ETR Valves

Instruction Manual

Form 5050

August 2006

8

PACKING

BOX

NOTE:

REFER TO FIGURE 5 OR 6 FOR PACKING ARRANGEMENTS.

1

1

10A6681-A / DOC

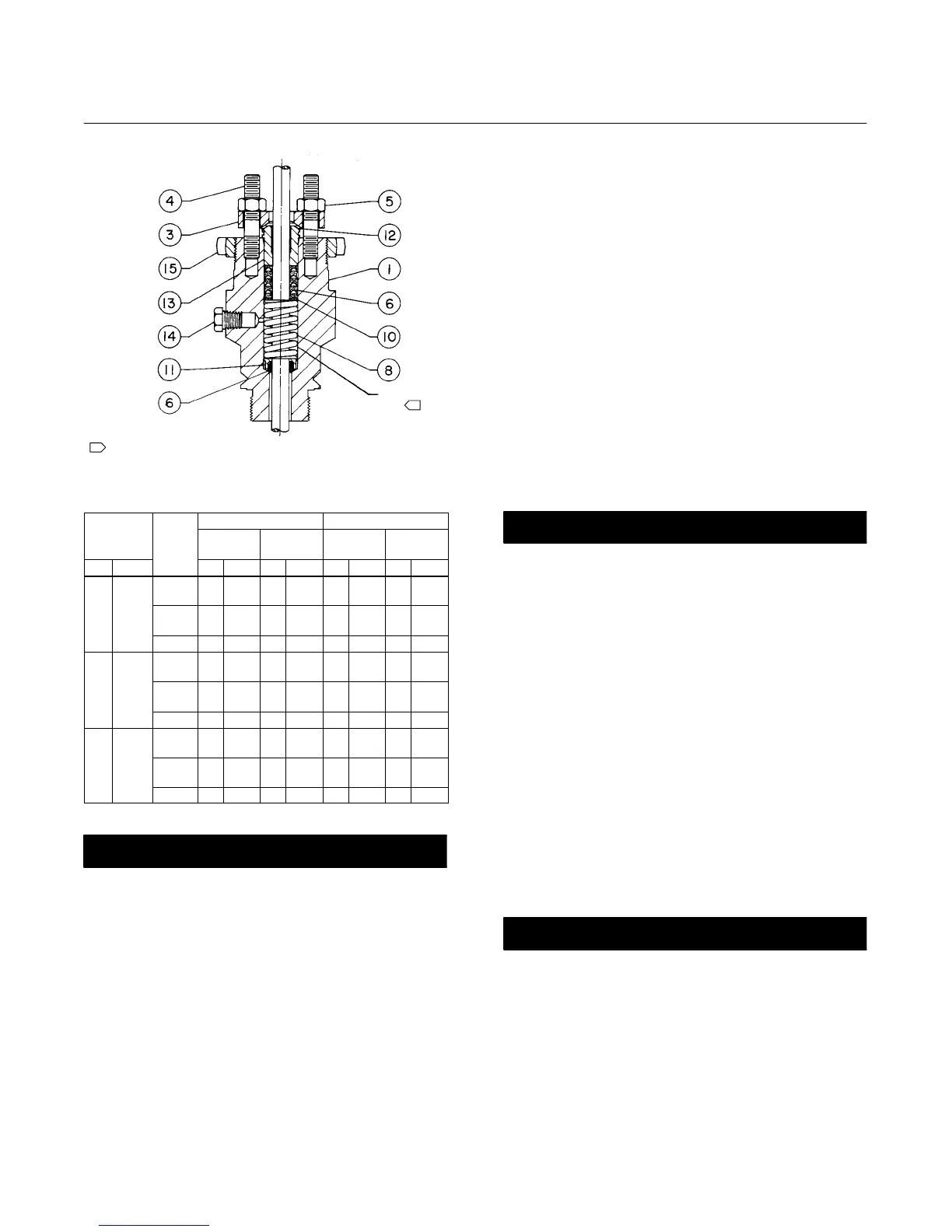

Figure 4. Bonnet Assembly

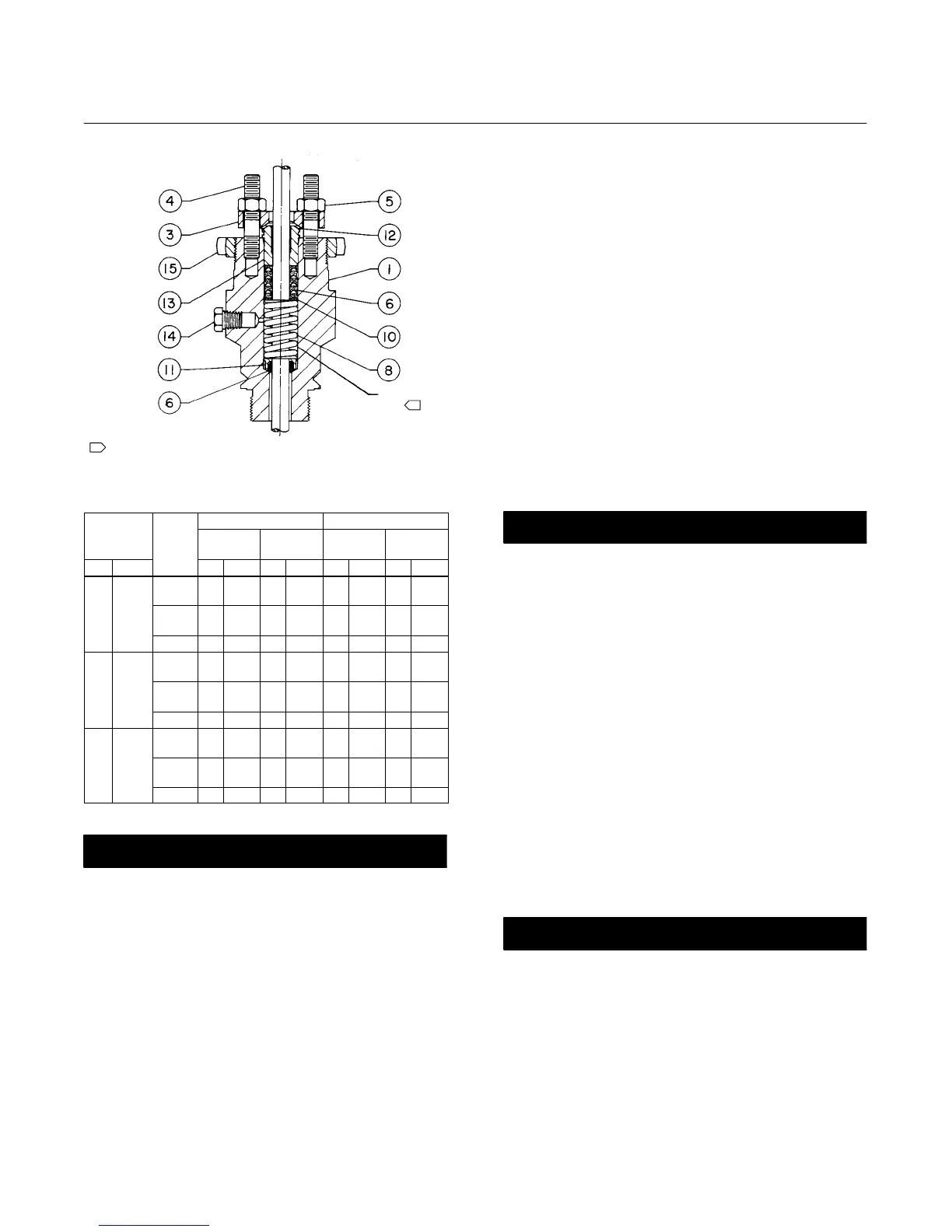

Table 4. Recommended Torque for Packing Flange Nuts

VALVE

STEM

DIAMETER

CLASS

GRAPHITE PACKING PTFE PACKING

Minimum

Torque

Maximum

Torque

Minimum

Torque

Maximum

Torque

mm Inches

NSm LbfSin NSm LbfSin NSm LbfSin NSm LbfSin

9.5 3/8

125,

150

3 24 5 48 1 12 3 24

250,

300

4 36 7 60 2 18 3 30

600 5 48 8 72 3 24 4 36

12.7 1/2

125,

150

5 48 8 72 3 24 4 36

250,

300

7 60 10 84 3 30 5 42

600 10 84 14 120 5 42 7 60

19.1 3/4

125,

150

11 96 16 144 5 48 8 72

250,

300

14 120 20 180 7 60 10 90

600 20 180 30 264 10 90 15 132

CAUTION

To prevent possible product damage,

avoid scratching the packing box walls

when removing old packing parts. Also

inspect valve stem threads and

packing box surfaces for sharp edges

which may damage packing.

6. Avoid scratching the packing box walls when

removing the old packing parts. Clean the packing

box (see figure 4), and clean, inspect, or replace

metal packing parts. Generally, the metal packing

parts are not part of the packing kits listed in the

Parts List section, and they must be ordered

individually.

7. Inspect the valve stem threads and packing box

surfaces for any sharp edges which might cut the

packing. Scratches or burrs on the stem surfaces

can cause packing box leakage or damage to new

packing. If the surface condition cannot be improved

by light sanding, replace the damaged parts by

following the appropriate steps in the Trim

Maintenance procedure.

Note

If the control valve assembly was

purchased for an application where the

service temperatures are under 232_C

(450_F), the bonnet may be unscrewed

from the valve body. Where

temperatures are greater than 232_C

(450_F), the bonnet is seal welded to

the valve body.

CAUTION

To prevent possible product damage,

set the bonnet on a protective surface

in the following procedure.

8. If necessary, remove the bonnet assembly from

the valve by unscrewing it. Some applications

require seal welding the bonnet to the valve body,

and the bonnet should not be removed. Set the

bonnet on a protective surface to prevent damage to

the bonnet gasket surface.

Installing Packing

If the trim is removed, refer to Trim Maintenance

procedures, and install the trim (including the valve

stem) before installing the packing. If necessary, use

the Lapping Metal Seats procedures before installing

packing. Key number locations are shown in figure 5

or 6 unless otherwise indicated.

CAUTION

To prevent possible product damage,

take care when installing the bonnet

over the valve stem in the following

procedure.

1. If the bonnet has been removed from the valve

body, install the replacement bonnet (see figure 4).

Carefully slide the bonnet over the valve stem

without damaging the stem surfaces.

Loading...

Loading...