Instruction Manual

D103175X012

GX Valve and Actuator

April 2011

8

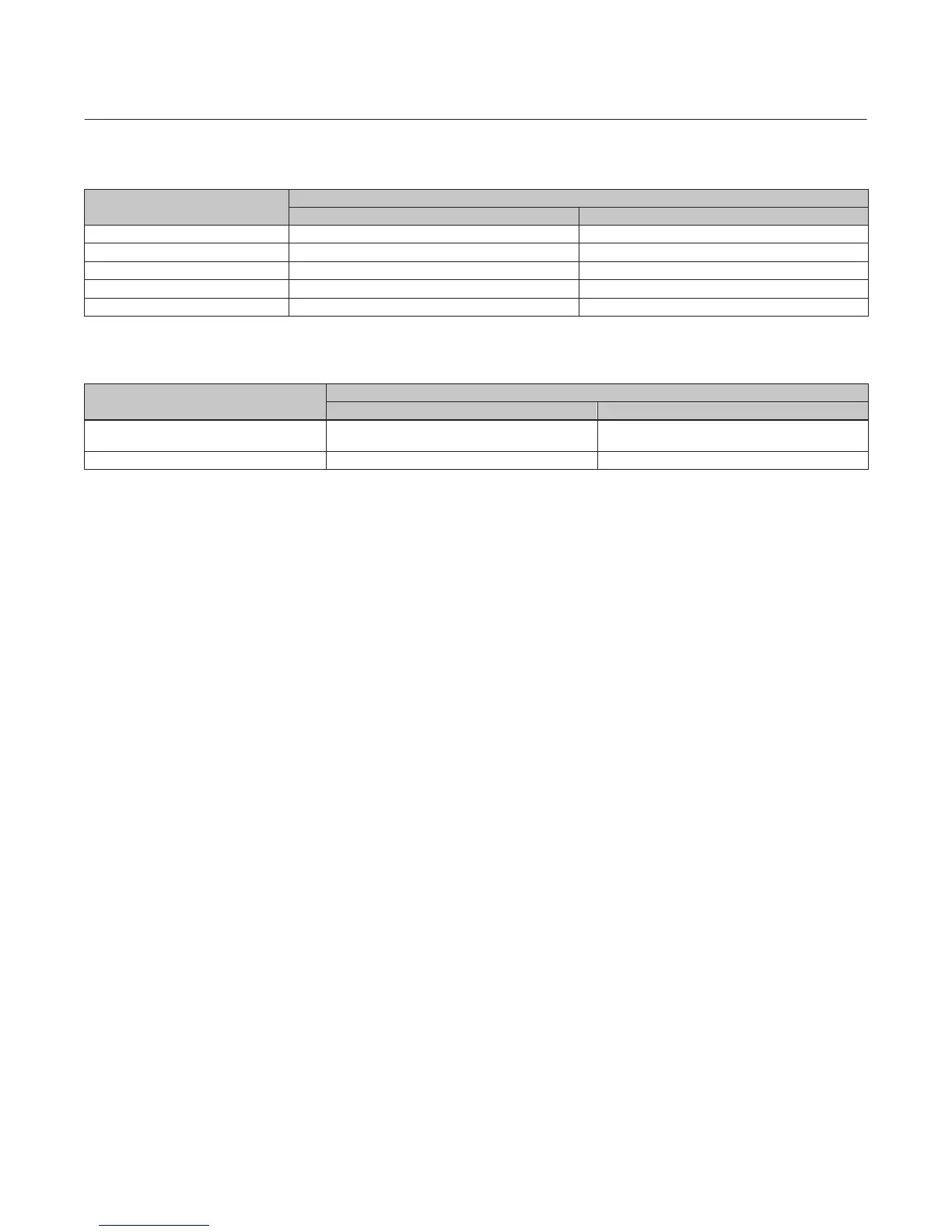

Table 4. Body Nut (Key 7) Torque Requirements

VALVE SIZE

TORQUE

NSm lbfSft

DN 15, 20, 25 (NPS 1/2, 3/4, 1) 45.5 33.5

DN 40 (NPS 1‐1/2) 79.8 58.9

DN 50 (NPS 2) 79.8 58.9

DN 80 (NPS 3) 163 120

DN 100 and DN 150 (NPS 4 and 6) 282 208

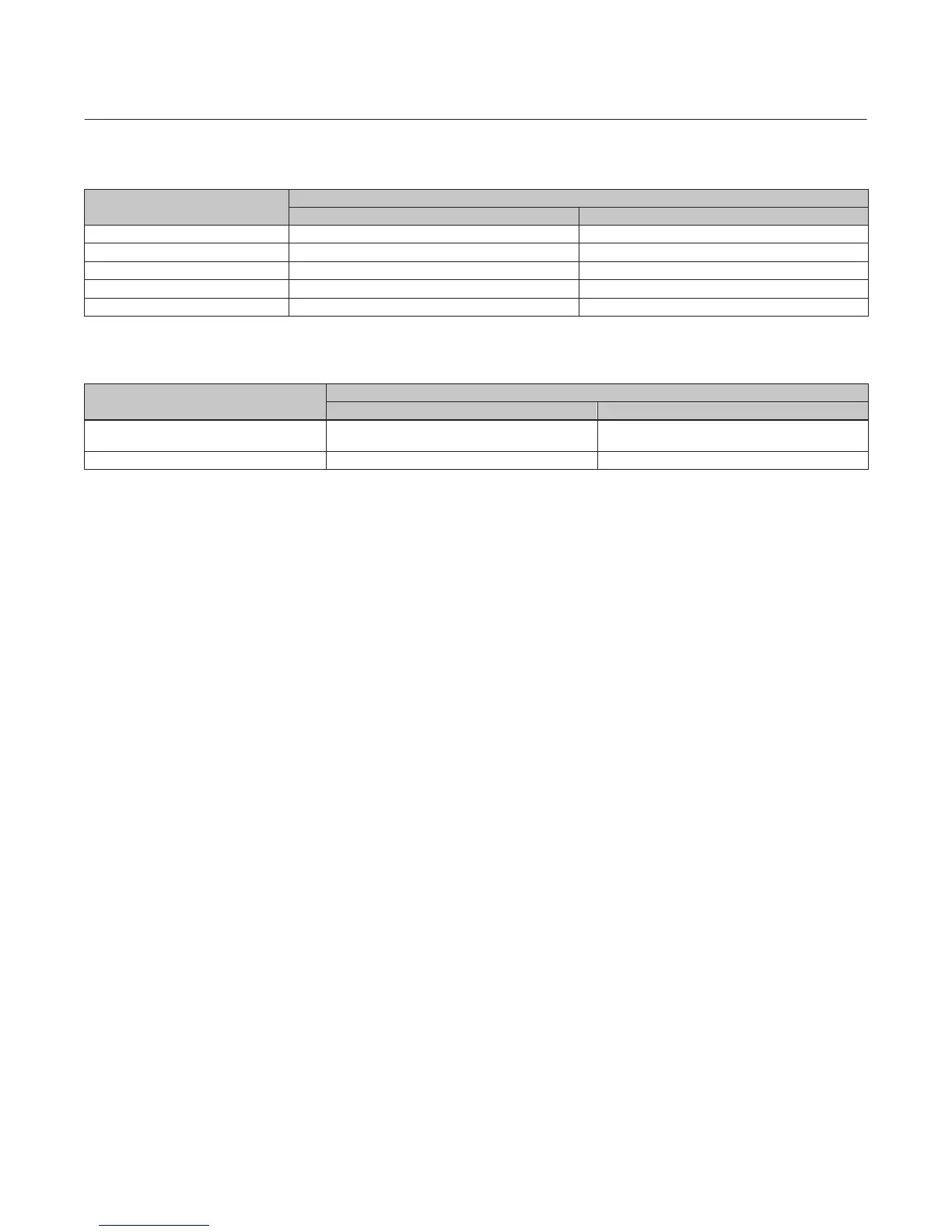

Table 5. Yoke/Extension Bonnet Nut (Key 46) Torque Requirements (used on Extension Bonnet and Bellows Bonnet

constructions)

VALVE SIZE

TORQUE

NSm lbfSft

DN 15, 20, 25, 40, and 50 (NPS 1/2, 3/4, 1,

1‐1/2, and 2)

79.8 58.9

DN 80 and 100 (NPS 3 and 4) 163 120

Actuator Assembly For Air‐to‐Open Constructions (or to Change Action to Air‐to‐Open ‐ see

figure 18 or 19)

1. Install the diaphragm (key 10) on the diaphragm plate (key 11). Insert the cap screw (key 14) through the actuator

spacer (key 13) and place this assembly through the diaphragm/diaphragm plate assembly.

2. Place the washer (key 15) over the center hole of the diaphragm, so that the convex part of the washer is facing

down toward the diaphragm.

3. Screw the actuator rod (key 22) onto the cap screw (key 14) and torque to 80 NSm (59.1 lbfSft). Install the actuator

stem/diaphragm assembly back into the actuator yoke (key 8).

4. Place the actuator springs (key 12 and/or 82) onto the spring locators in the diaphragm plate (key 11). See figure 3

and table 2 for proper spring quantity and arrangement.

D If the nameplate does not contain spring information, use the same quantity and arrangement as originally

installed.

5. Install the upper diaphragm casing (key 9) so that the ribs on the top of the upper diaphragm casing are

perpendicular with the yoke legs.

D For size 225 and 750 actuators, install the 2 long cap screws (key 16) and hex nuts (key 18) 180 degrees apart from

each other and in line with the actuator yoke legs.

D For size 1200 actuators, install the 4 long cap screws (key 16) and hex nuts (key 18) 90 degrees from each other,

with two of them in line with the actuator yoke legs.

6. Tighten the long cap screws (key 16) and hex nuts (key 18), alternating between them to gradually compress the

springs, until the two casing halves and diaphragm touch.

7. Install the remaining short cap screws (key 17) and hex nuts (key 18) to the casing.

8. Tighten the actuator casing cap screws evenly using a cross‐tightening procedure. Torque to 55 NSm (40 lbfSft).

9. If you had previously removed the actuator assembly from the valve, place the actuator assembly back onto the

valve body (key 1). Install the four body nuts (key 7), but tighten them only finger‐tight.

Loading...

Loading...