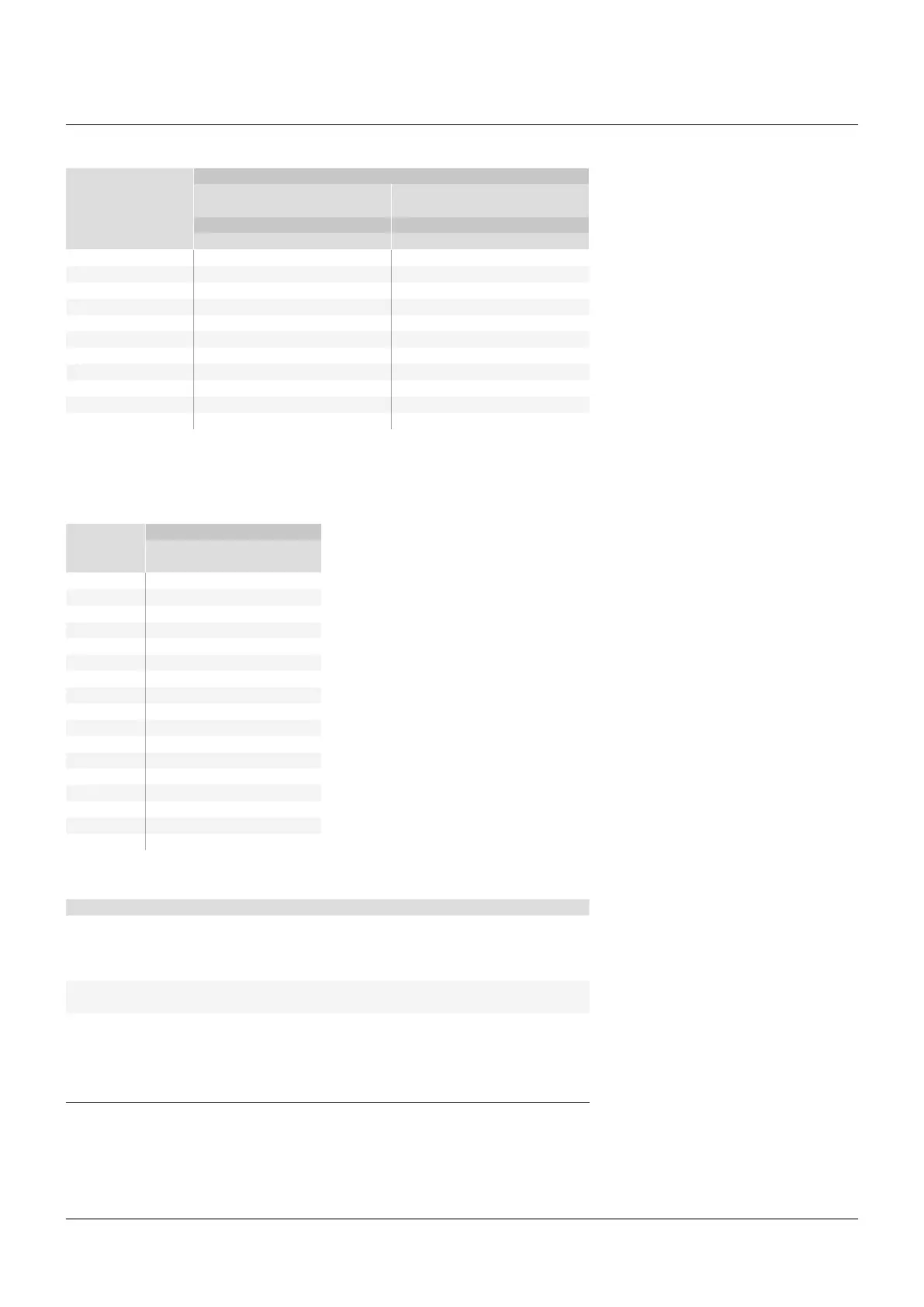

11

M10 10 7 20 15

M12 15 11 25 18

M14 20 15 45 33

M16 25 18 60 44

M18 30 22 65 48

M20 80 59 200 148

M24 180 133 340 251

M27 210 155 375 277

M30 290 214 495 366

M33 310 229 700 517

M42 - - 1250 923

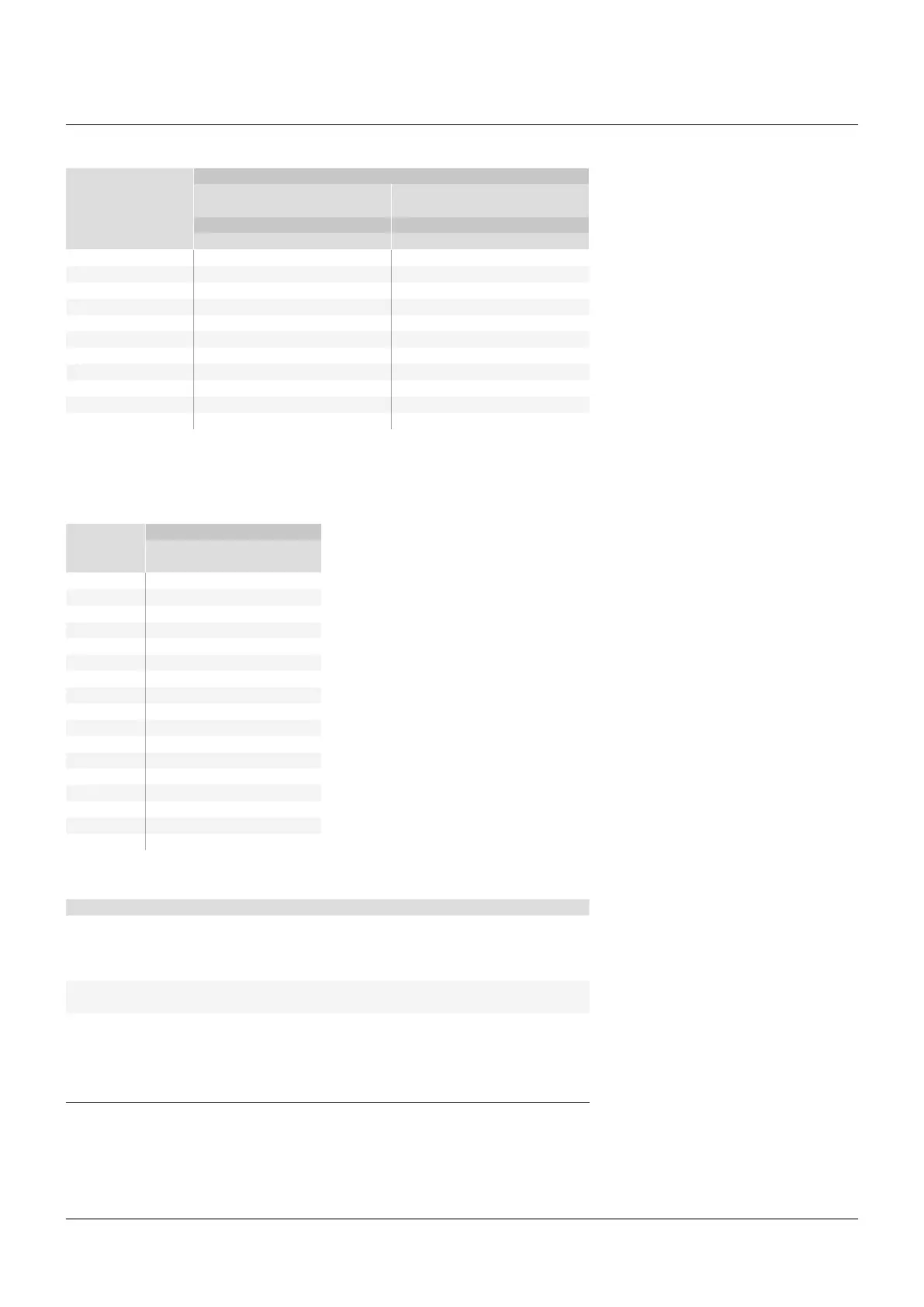

M6 10 7

M8 20 15

M10 45 33

M12 70 52

M14 110 81

M16 175 129

M18 235 173

M20 335 247

M22 370 273

M24 460 339

M27 595 439

M30 760 561

M33 785 579

M36 1010 745

M39 1315 970

M42 1625 1199

M45 2035 1501

VANESSA SERIES 30,000 TRIPLE OFFSET VALVE (TOV)

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TABLE 1 - TORQUE VALUES FOR PACKING FLANGE NUTS

Bolt dimensions

mm

Nominal pressure

ASME CLASS 150 - 300

EN PN 10 - 16 - 25 - 40

ASME CLASS 600 - 900 - 1500

EN PN 63 - 100 - 110 - 150 - 260

Torque Torque

Nm ft·lb Nm ft·lb

TABLE 2 - General torque values for retainer

flange and bottom flange bolting

Bolt

dimensions

(mm)

Torque values

Torque

(Nm)

Torque

(ft·lb)

TABLE 3 - Lubrication

Type Component to lubricate

Light mineral oil

1. Packing rings (5a)

2. Disc surface areas (2a) for seal ring and spiral wound

gasket location

3. Spiral wound gasket (6c)

Molykote

®

- P74 (grease) or equivalent

1. Stud bolts/nuts (5d)

2. Screw (6b)

Molykote

®

spray - 321R (dry lubricant) or

equivalent

1. Seal ring (3a)

2. Body seat

NOTE

Tighten the packing flange nuts slowly and evenly

until the leakage stops. The torque values are max

suggested value.

SECTION 6 - DECOMMISSIONING

Instruction for decommissioning

Comply with the national regulations for disposal and recycling.

The comprehensive list of materials is available in the relevant technical literature.

Loading...

Loading...